Full hand clothes washing method

A technology of manual and laundry equipment, which is applied in the direction of manual washing utensils, chemical instruments and methods, washing equipment, etc., which can solve the problems of labor-consuming and insufficient removal of oil stains, and achieve the effect of good cleaning effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

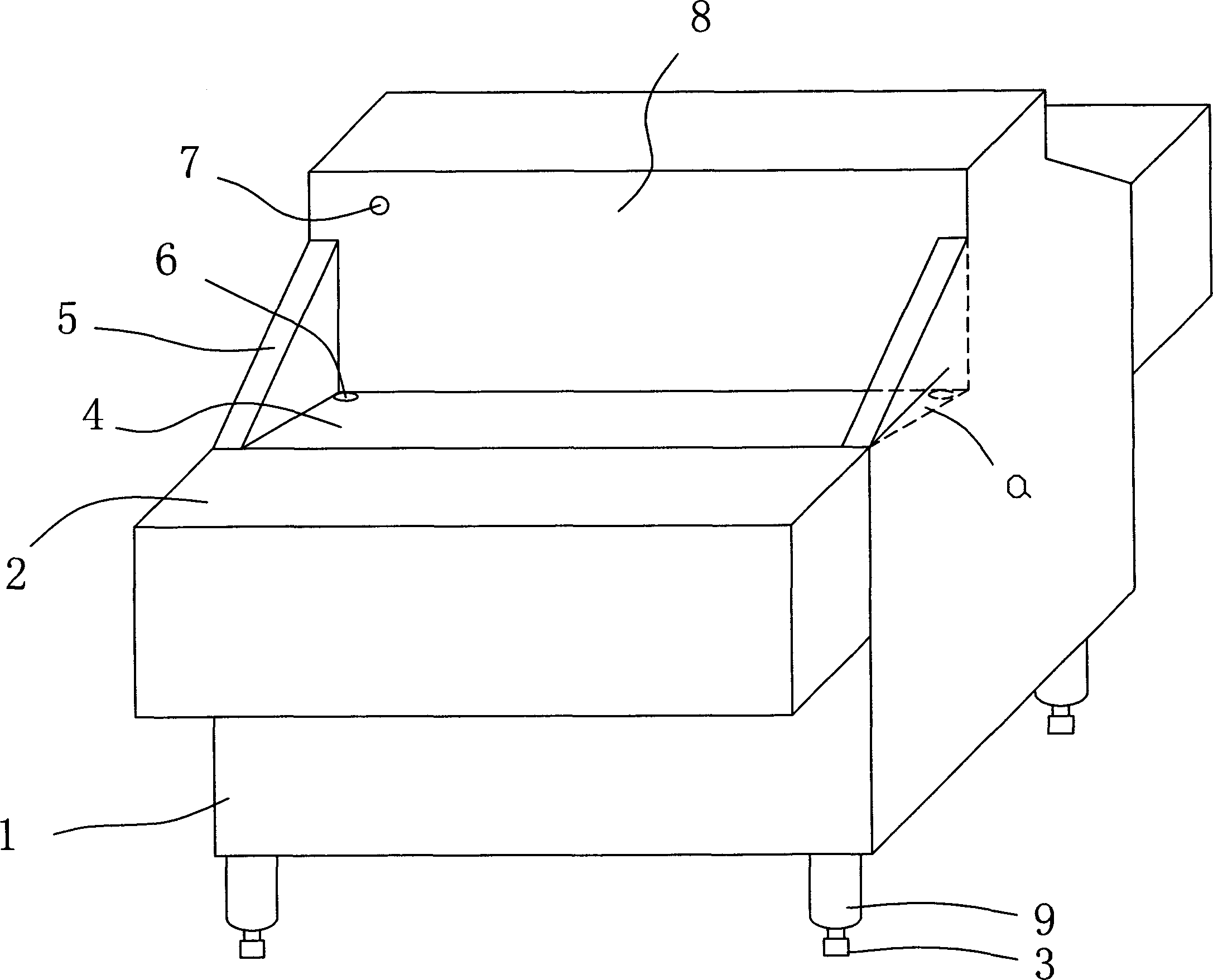

[0016] Such as figure 1 Shown, the present invention comprises the steps:

[0017] 1) Carry out an overall inspection of the clothes to determine the parts of heavy dirt and ordinary dirt;

[0018] 2) Place the heavily dirty parts evenly on the horizontal stain-removing table of the washing machine, and apply an appropriate amount of laundry descaling agent, and use a stain-removing brush to scrub first. The clothing descaling agent consists of 1% glycol ether, Fatty alcohol polyoxyethylene ether 15%, the balance is made of water;

[0019] 3) The clothes after above-mentioned scrubbing are placed in the laundry detergent and soaked for 2 to 5 minutes. The laundry detergent is composed of AES (coco-based polyoxyethylene ether sodium sulfate) 5%, alkylbenzene sulfate 10%, coconut oil fatty acid ethanol Amide 2%, fatty alcohol polyoxyethylene ether 1%, and the balance is water;

[0020] 4) Re-place the soaked clothes on the inclined laundry table of the laundry device and scru...

Embodiment 2

[0025] The steps of the present invention include:

[0026] 1) Carry out an overall inspection of the clothes to determine the parts of heavy dirt and ordinary dirt;

[0027] 2) Place the heavily dirty parts evenly on the horizontal stain-removing table of the washing machine, and apply an appropriate amount of laundry descaling agent, and use a stain-removing brush to scrub first. The clothing descaling agent consists of 5% glycol ether, Fatty alcohol polyoxyethylene ether 15%, the balance is made of water;

[0028] 3) The clothes after above-mentioned scrubbing are placed in the laundry liquid and soaked for 2 to 5 minutes, and the laundry liquid is composed of 15% AES (sodium coco polyoxyethylene ether sulfate), 3% alkylbenzene sulfate, coconut oil fatty acid ethanol Amide 2%, fatty alcohol polyoxyethylene ether 1%, and the balance is water;

[0029] 4) Re-place the soaked clothes on the inclined laundry table of the laundry device and scrub them with a brush for 2 to 5 m...

Embodiment 3

[0033] The steps of the present invention include:

[0034] 1) Carry out an overall inspection of the clothes to determine the parts of heavy dirt and ordinary dirt;

[0035] 2) Place the heavily dirty parts evenly on the horizontal stain-removing table of the washing machine, and apply an appropriate amount of laundry descaling agent, and use a stain-removing brush to scrub first. The clothing descaling agent consists of 3% glycol ether, Fatty alcohol polyoxyethylene ether 15%, the balance is made of water;

[0036] 3) The clothes after above-mentioned scrubbing are placed in the laundry liquid and soaked for 2 to 5 minutes, and the laundry liquid is composed of AES (coco-based polyoxyethylene ether sodium sulfate) 7%, alkylbenzene sulfate 6%, coconut oil fatty acid ethanol Amide 3%, fatty alcohol polyoxyethylene ether 3%, and the balance is water;

[0037] 4) Re-place the soaked clothes on the inclined laundry table of the laundry device and scrub them with a brush for 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com