Co-burning method for oxygen sensor electrolyte and palatinum electrode

An oxygen sensor and electrolyte technology, applied in instruments, circuits, scientific instruments, etc., can solve the problems of cumbersome process, long time to reach working temperature, slow response, etc., and achieve the effect of reducing volume, fast response, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] By weight percent, 55% doped Y8mol% ZrO 2 Base electrolyte and 45% polyvinyl alcohol binder ingredients are ball milled, cast into a 0.15mm film, and superimposed into 5 layers, isostatically pressed into a laminated film, and cut according to the designed size; the platinum electrode slurry The composition in weight percent is 71.8% of Pt, 28% of binder (30% of ethyl cellulose and 70% of terpineol), and 0.2% of glass to make platinum electrode slurry. Make a printing screen according to the size of the electrode, and use a thick film process to print the platinum electrode on the laminated diaphragm. The thickness of the platinum electrode is 50-150um. Cut the diaphragm according to the size of the oxygen sensor, degrease, and burn to 1560°C , heat preservation for 4 hours, the two are combined into a whole.

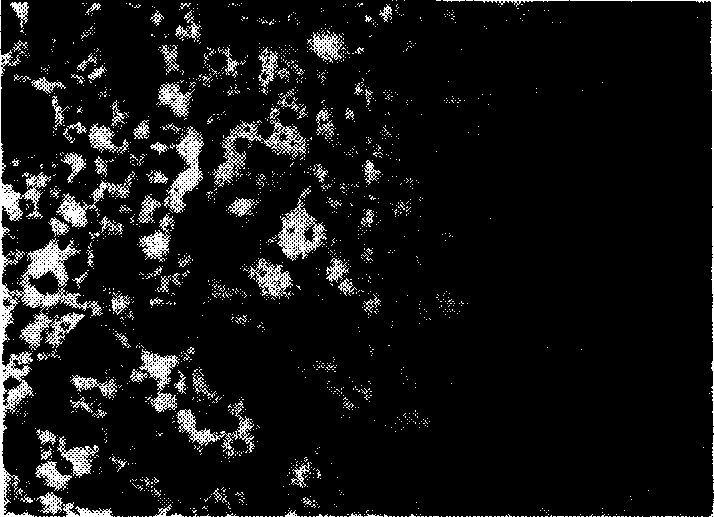

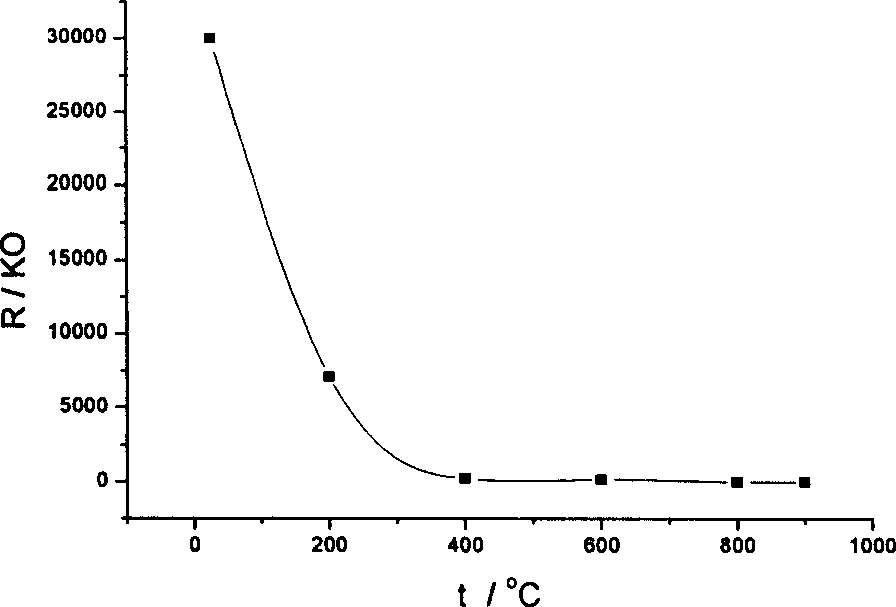

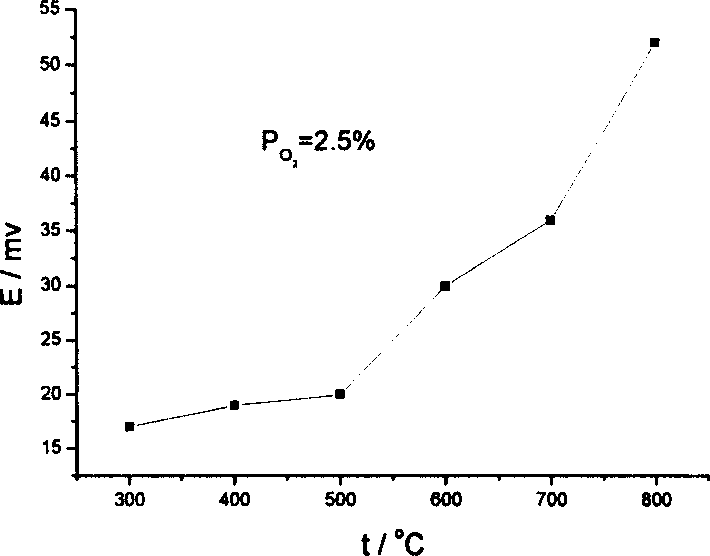

[0023] Take the sample prepared by co-firing the electrolyte of the oxygen sensor prepared by the above method and the platinum electrode and observe the electr...

Embodiment 2

[0025] By weight percentage, 50% doped Y 5mol% ZrO 2 Base electrolyte and 50% polyvinyl alcohol binder ingredients are ball milled, cast into a 0.10mm film, and superimposed into 6 layers, isostatically pressed into a laminated film, and cut according to the designed size; the platinum electrode slurry The composition in weight percentage is 85% of Pt, 15% of binder (components are 20% of ethyl cellulose and 80% of terpineol) to make platinum electrode slurry. Make a printing screen according to the size of the electrode, and use a thick film process to print the platinum electrode on the laminated diaphragm. The thickness of the platinum electrode is 50-120um. Cut the diaphragm according to the size of the oxygen sensor, degrease, and burn to 1600°C , heat preservation for 2 hours, the two are combined into a whole.

[0026] Tested according to the method of Example 1, the electrode structure of the sample was observed under an electron microscope SEM, a porous network was s...

Embodiment 3

[0028] By weight percentage, 60% doped Y 10mol% ZrO 2 Base electrolyte and 40% butyral binder ingredients are ball milled, cast into a 0.20mm film, and superimposed into 3 layers, isostatically pressed into a laminated film, and cut according to the designed size; the platinum electrode slurry The composition in weight percent is 65% of Pt, 33% of binder (the components are 40% of ethyl cellulose and 60% of terpineol), and 2% of glass to make platinum electrode slurry. Make a printing screen according to the size of the electrode, and use a thick film process to print the platinum electrode on the laminated diaphragm. The thickness of the platinum electrode is 80-150um. Cut the diaphragm according to the size of the oxygen sensor, degrease, and burn to 1500°C , heat preservation for 6 hours, the two are combined into a whole.

[0029] Tested according to the method of Example 1, the electrode structure of the sample was observed under an electron microscope SEM, a porous netw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com