Waterdrop slidable surface structure

A surface structure and water skiing technology, applied in the field of water skiing surface structure, can solve the problems of poor durability, low wear resistance, poor adhesion of fluororesin, etc., and achieve the effect of wear suppression and shear force suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

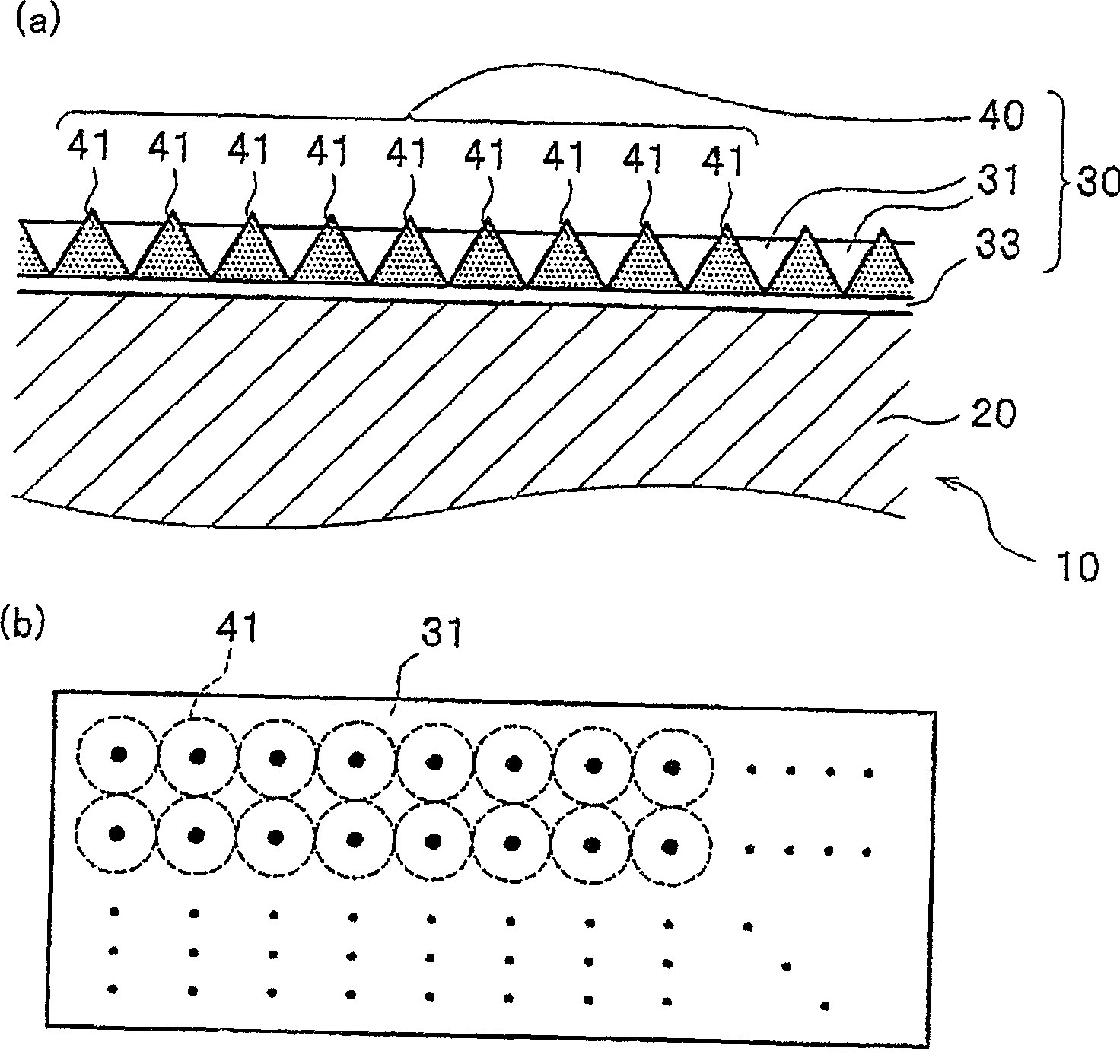

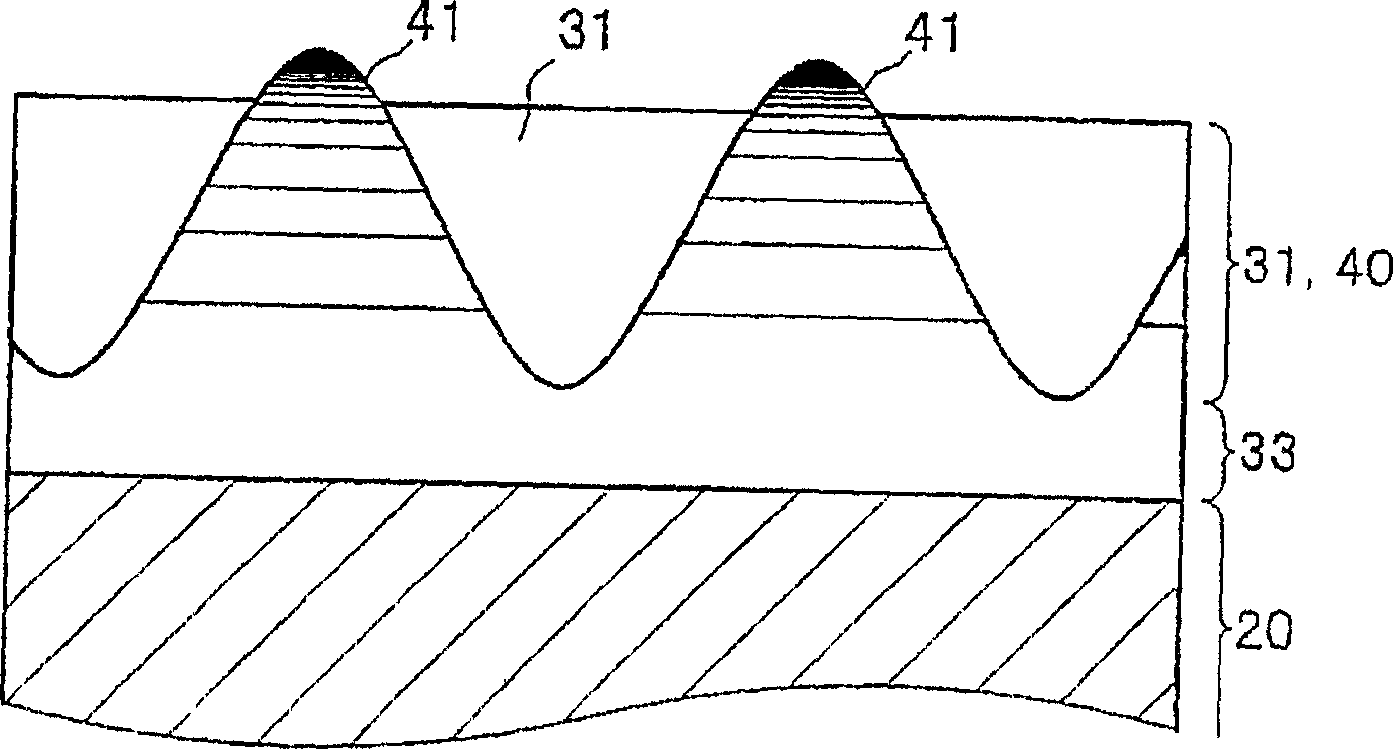

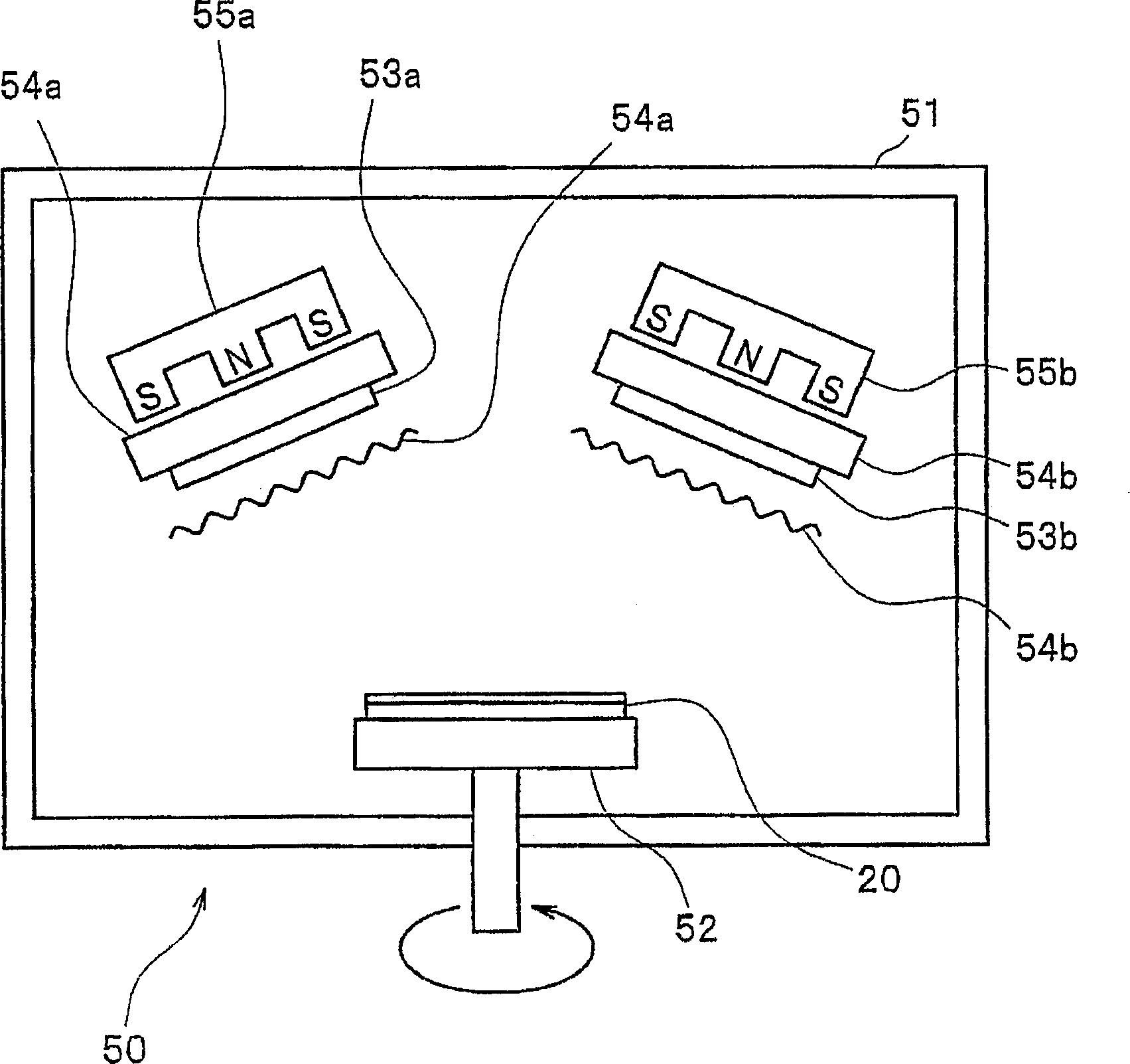

[0025] figure 1 It is a schematic diagram which shows the basic structure of the water-skiing surface structure in this embodiment, (a) is a cross-sectional view, (b) is a top view. figure 2 It is a cross-sectional view of a hard bump showing an enlarged basic structure of the water-skiing surface structure in this embodiment.

[0026] Such as figure 1 As shown, the glass substrate (substrate) 20 of the water slide glass 10 has a plate shape and can transmit visible light. The water slide glass 10 is provided with a water slide layer 30 on at least one surface of the glass substrate (substrate) 20. Moreover, this water ski layer 30 is composed of a hydrophobic layer 31, a hard layer 40, and a buffer layer 33.

[0027] The hard layer 40 is an assembly of hard protrusions 41. The top ends of these hard protrusions 41 are convex and the shape is roughly conical. They are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com