Method for increasing refrigerating quantity and reducing power of air conditioner and air conditioning device

A high-pressure refrigerant and power technology, used in refrigerators, refrigeration components, air-conditioning systems, etc., can solve problems such as reducing refrigeration capacity, increasing refrigeration system load, reducing evaporator evaporation effect, etc., to improve refrigeration capacity and improve refrigeration capacity. , the effect of reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

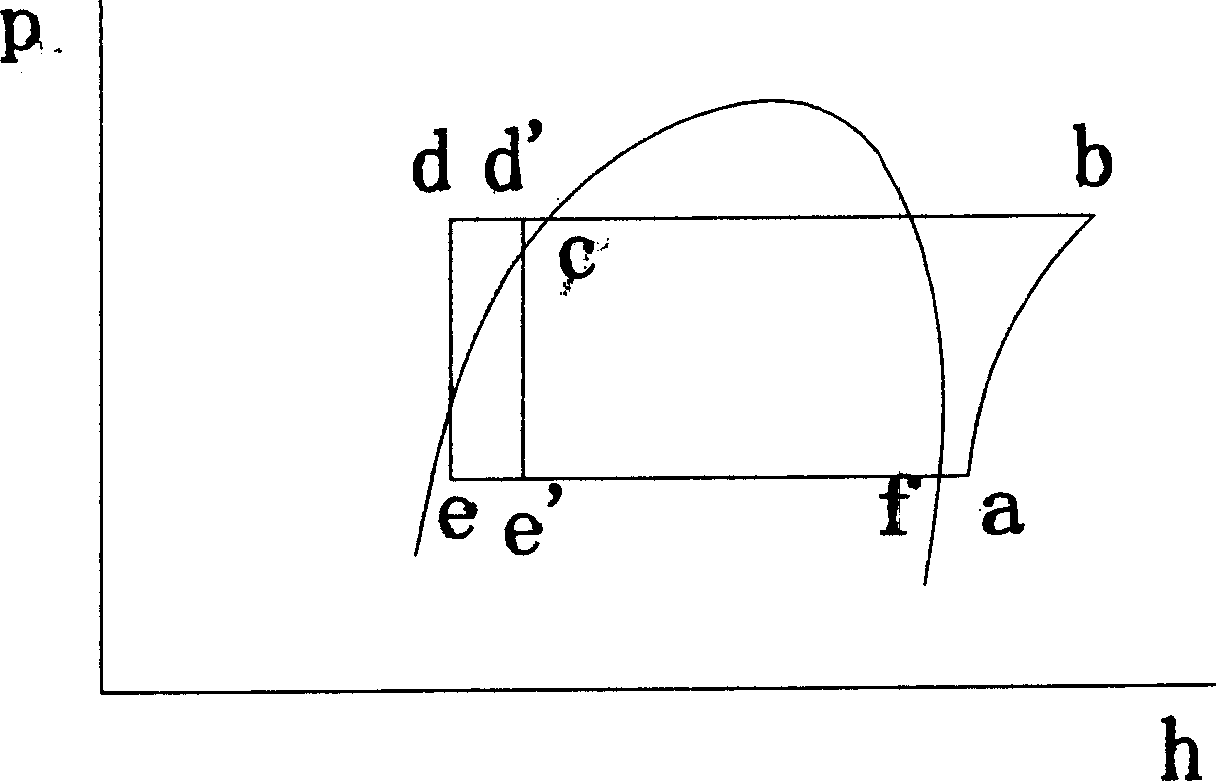

[0011] figure 1 It is the pressure enthalpy diagram of refrigeration principle. The compressor sucks low-pressure and low-temperature gaseous refrigerant a, which is compressed into high-temperature and high-pressure gaseous refrigerant b; b is condensed by the condenser to become high-pressure and medium-temperature liquid refrigerant c; c is further cooled to become d with constant pressure and lower temperature ; c-d is called the subcooling cooling process, also called the degree of supercooling, and the degree of supercooling increases, and the cooling capacity will increase accordingly; in the present invention, the copper pipe is cooled by the low-temperature condensed water in the indoor water tray after the condenser, and is connected at the same time The cooling of the high-pressure pipe in the pipe in the environment will increase the degree of subcooling in the present invention (the degree of subcooling of ordinary air conditioners is c-d'), and the cooling capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com