Reinforcement member, method of manufacturing reinforcement member, and engine block

A manufacturing method and component technology, applied in the direction of engine components, machines/engines, and rotating parts that resist centrifugal force, can solve problems such as poor adhesion, reduced thermal expansion suppression effect, and low strength, and achieve light weight and thermal expansion. Manufacturing Effects of cost reduction and low thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Composition of Embodiment

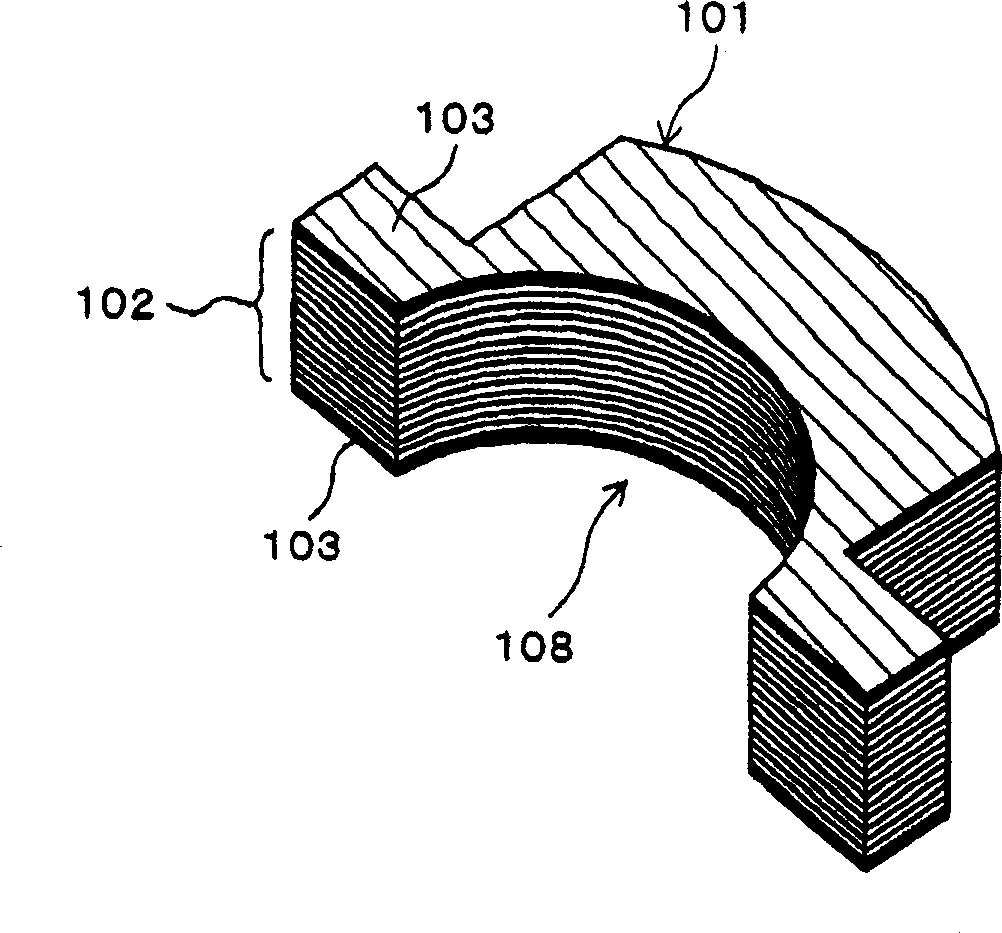

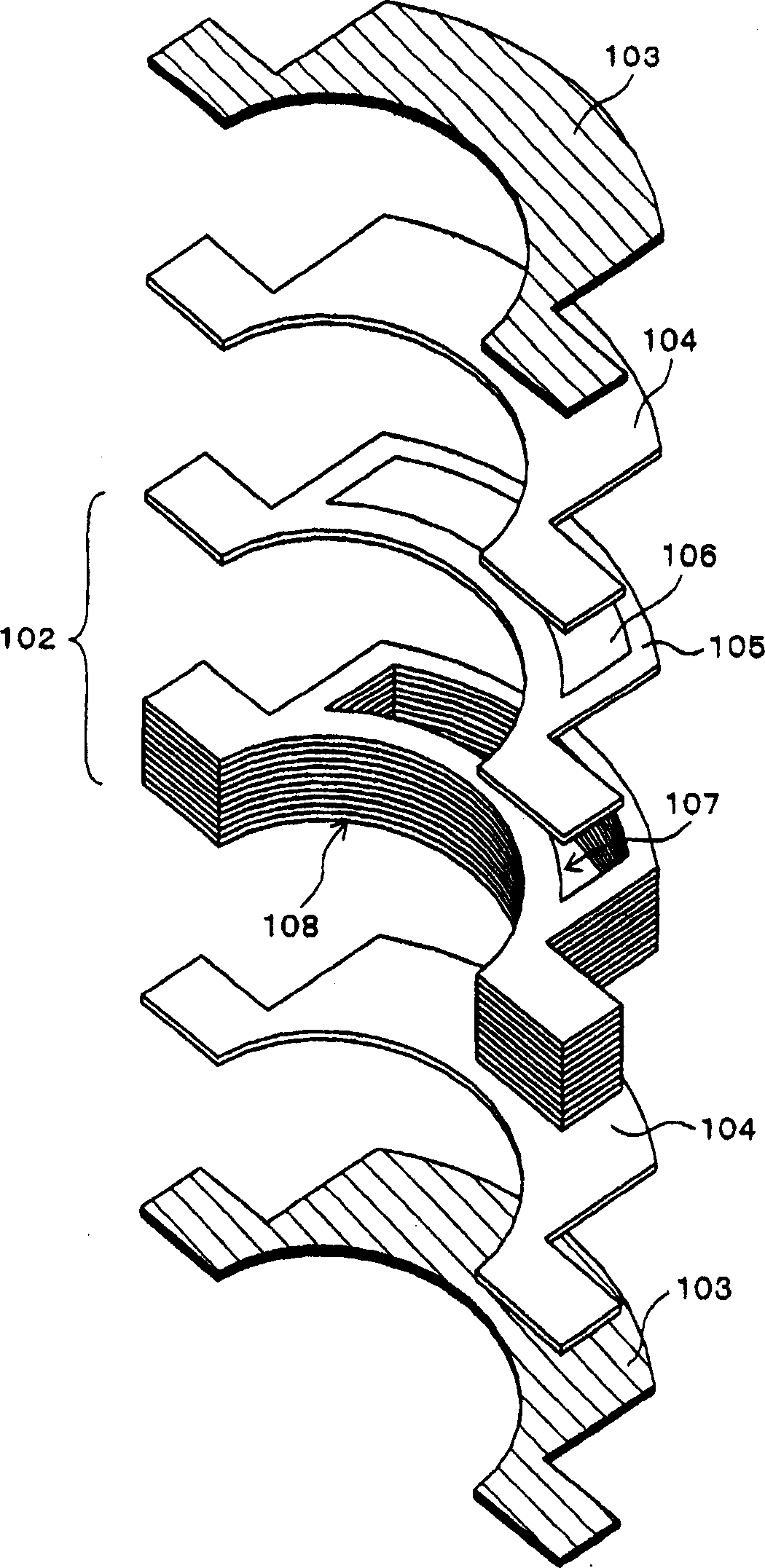

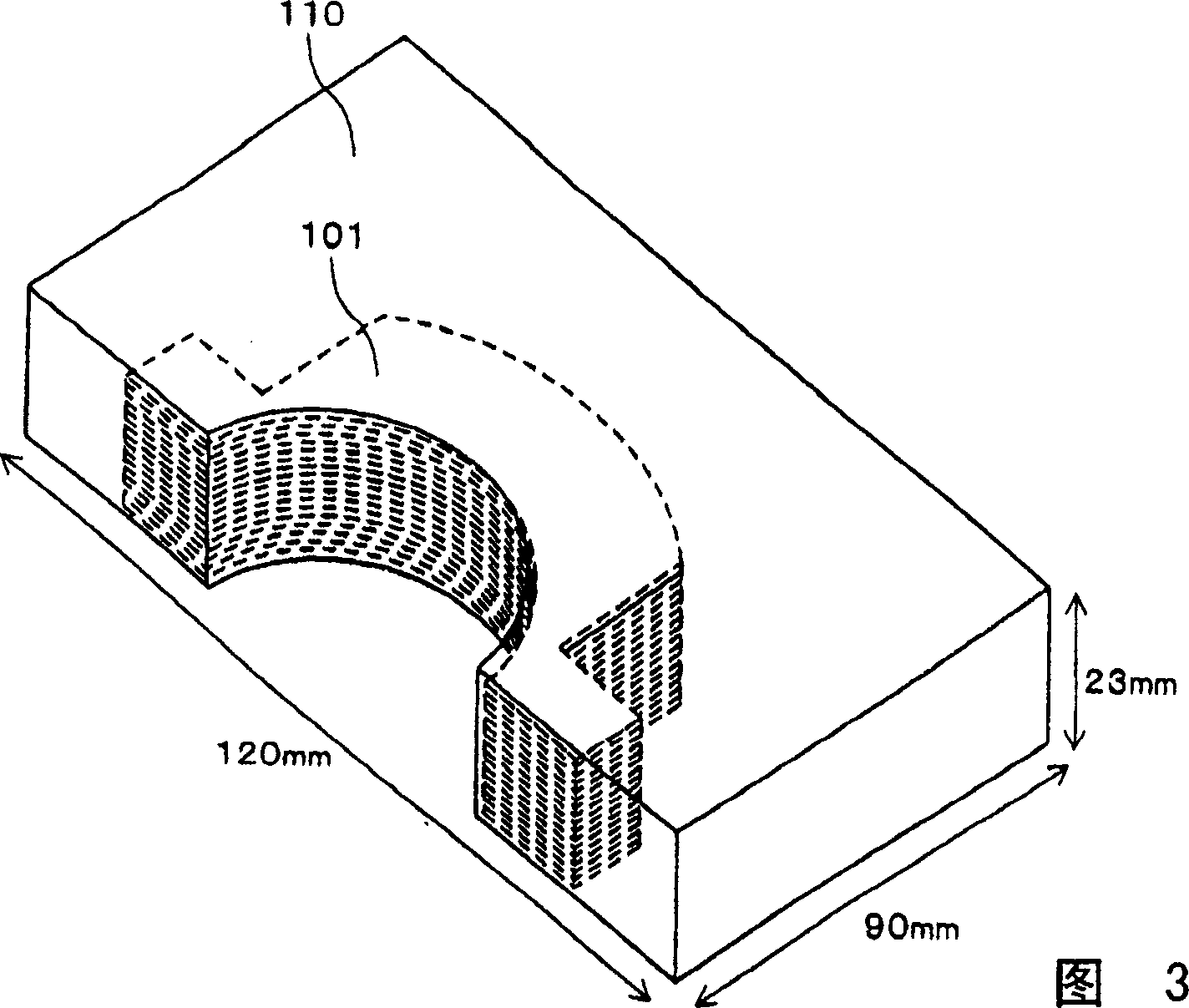

[0030] figure 1 It is a perspective view which shows the outline of the reinforcement member of this embodiment. figure 2 is the decomposition representation figure 1 An exploded perspective view of the reinforcement components shown. The reinforcing member 101 has a structure in which a laminated structure 102 formed by stacking thin iron plates, an iron plate 104 for closing an opening, and a porous body 103 are closely adhered to each other by sintering.

[0031] The laminated structure 102 is a main member constituting the reinforcing member 101 and has a hollow portion 107 formed therein. The laminated structure 107 has a structure in which multiple layers of iron plates 105 are stacked, and the iron plates 105 are punched to form an opening 106 constituting a hollow portion 107 . That is, the hollow portion 107 is formed by overlapping the opening portion 106 .

[0032] On the upper surface and the lower surface of the laminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com