Double-spring balancing type combined vibration damping support-hanger

A balanced and combined technology, applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of difficult matching of performance and large dispersion of spring performance, and achieve weight reduction, production difficulty, external good balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

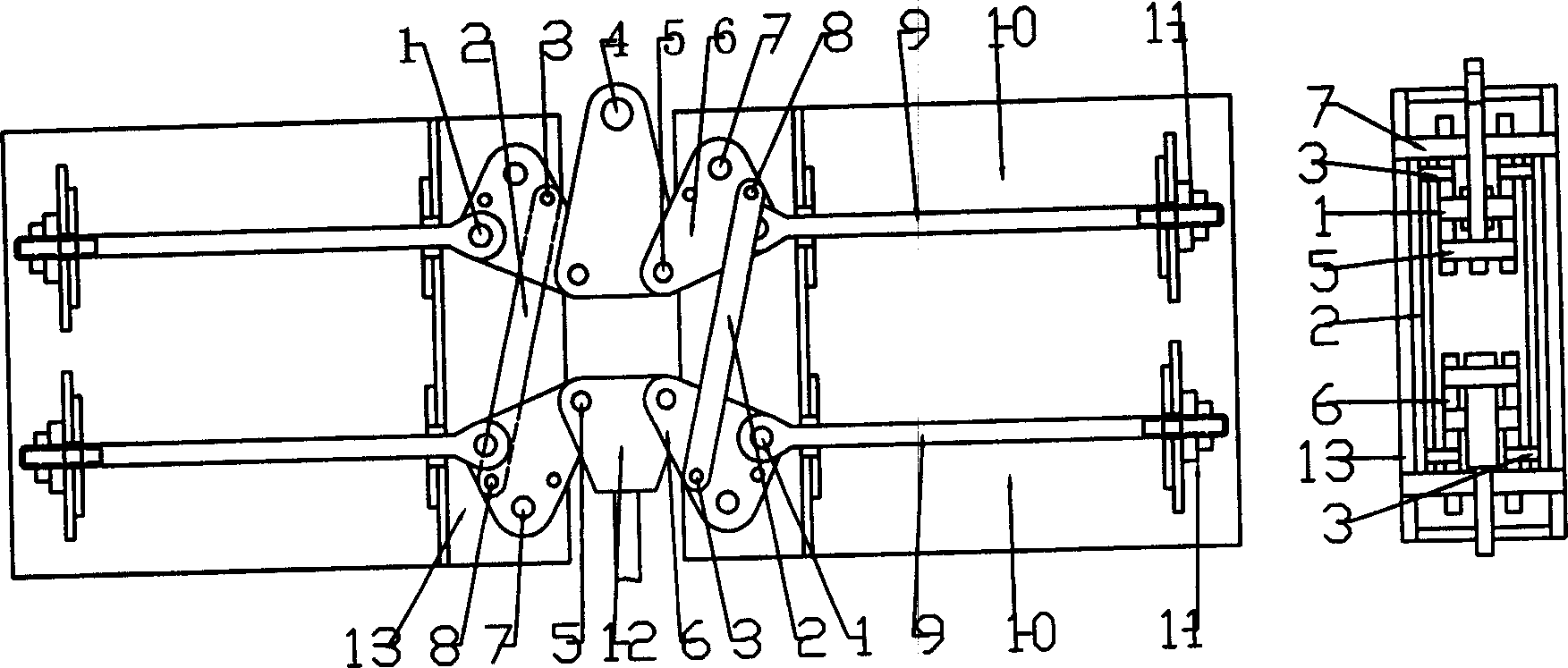

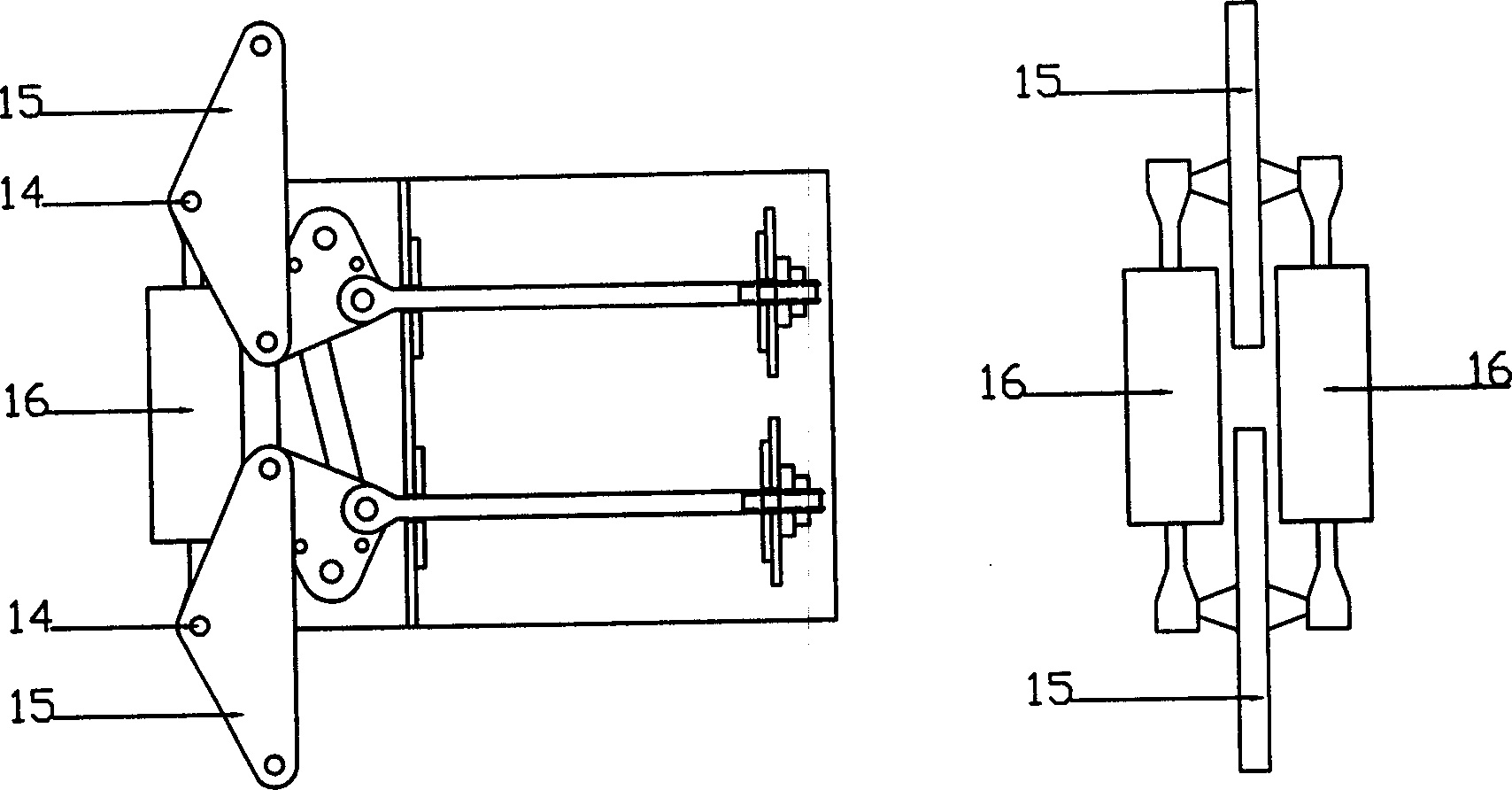

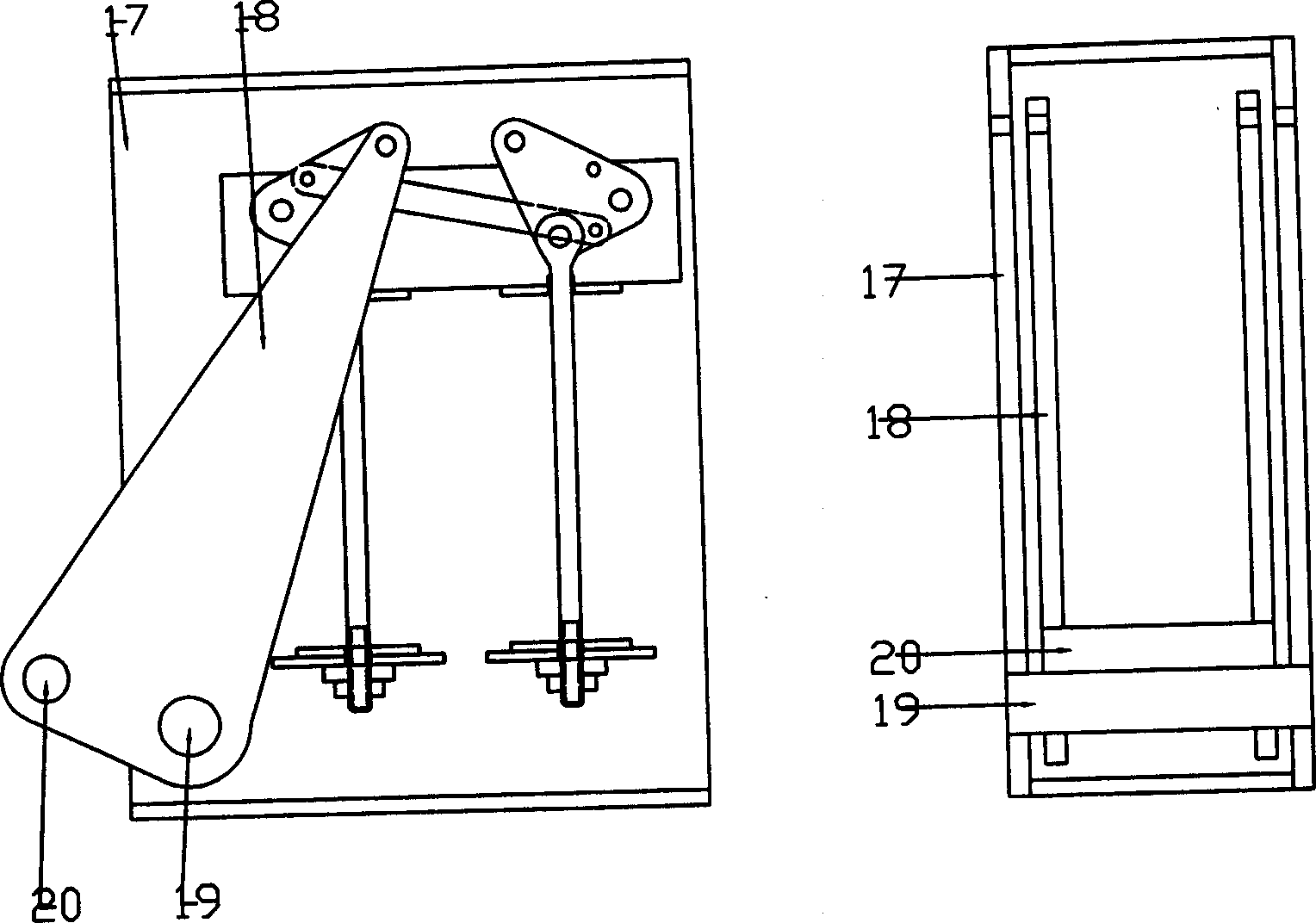

[0042] Combine below figure 1 Specific embodiments of the present invention are further described:

[0043] Depend on figure 1 It can be seen that when the upper load plate and the lower load plate are subjected to the force of lifting and pulling down in the vertical direction at the same time, the upper and lower slewing frames rotate along their respective main axes, and the upper and lower slewing frames simultaneously drive the upper and lower 9. The spring rod compresses the upper , Next 10. Spring.

[0044] If one spring is used, when the revolving frame equipped with the spring starts to rotate, the other revolving frame will also rotate under the action of the push-pull plate at the same time. The two revolving frames have the same rotation angle but opposite rotation directions. Quadrilateral double displacement amplifier.

[0045] In the same way, when two springs are used, the spring force with high spring force will make the two slewing frames rotate at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com