Immobilized xanthine oxidase, its prepn. and uses

A technology of xanthine oxidase and carbon nanotubes, which is applied in the field of immobilized xanthine oxidase and its preparation, can solve the problems that limit the practical application of carbon nanotubes, and achieve easy control of operating parameters, mild conditions, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

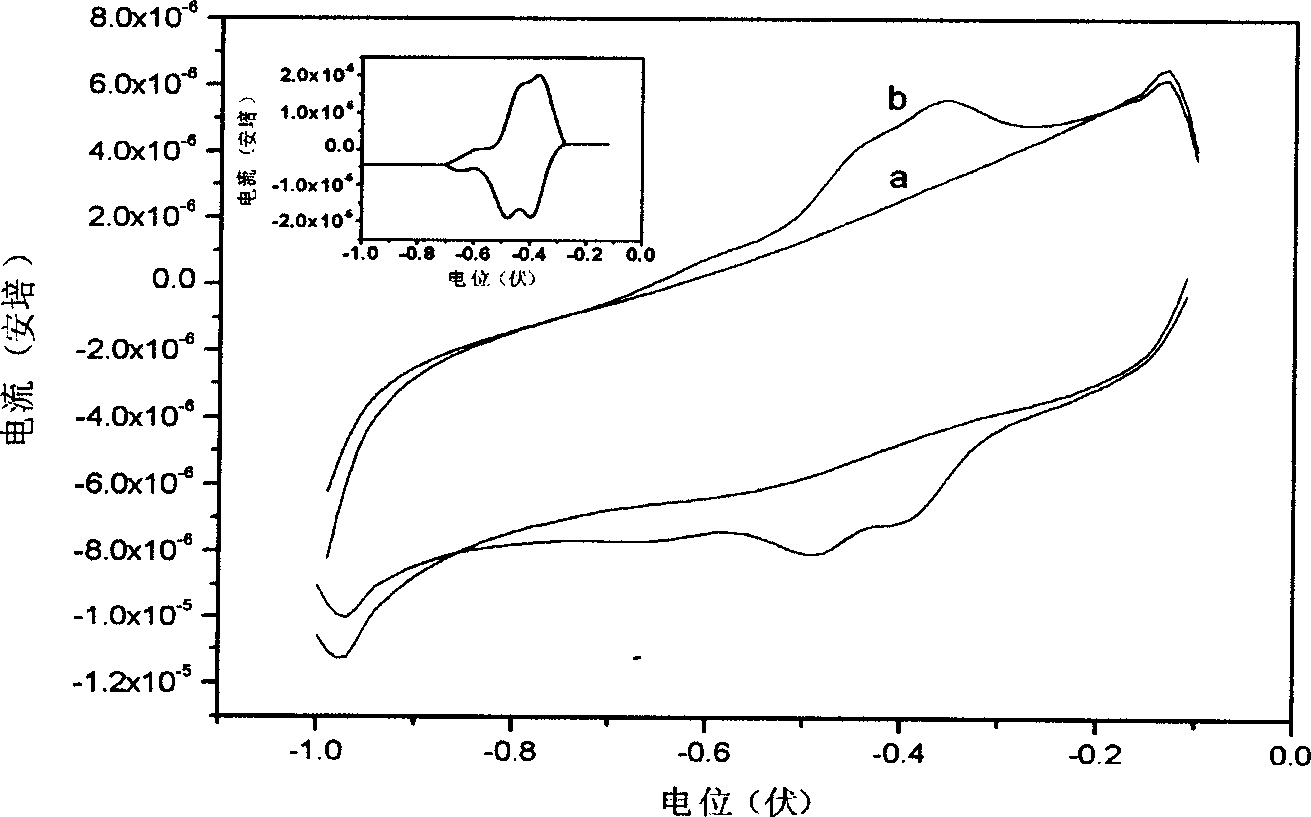

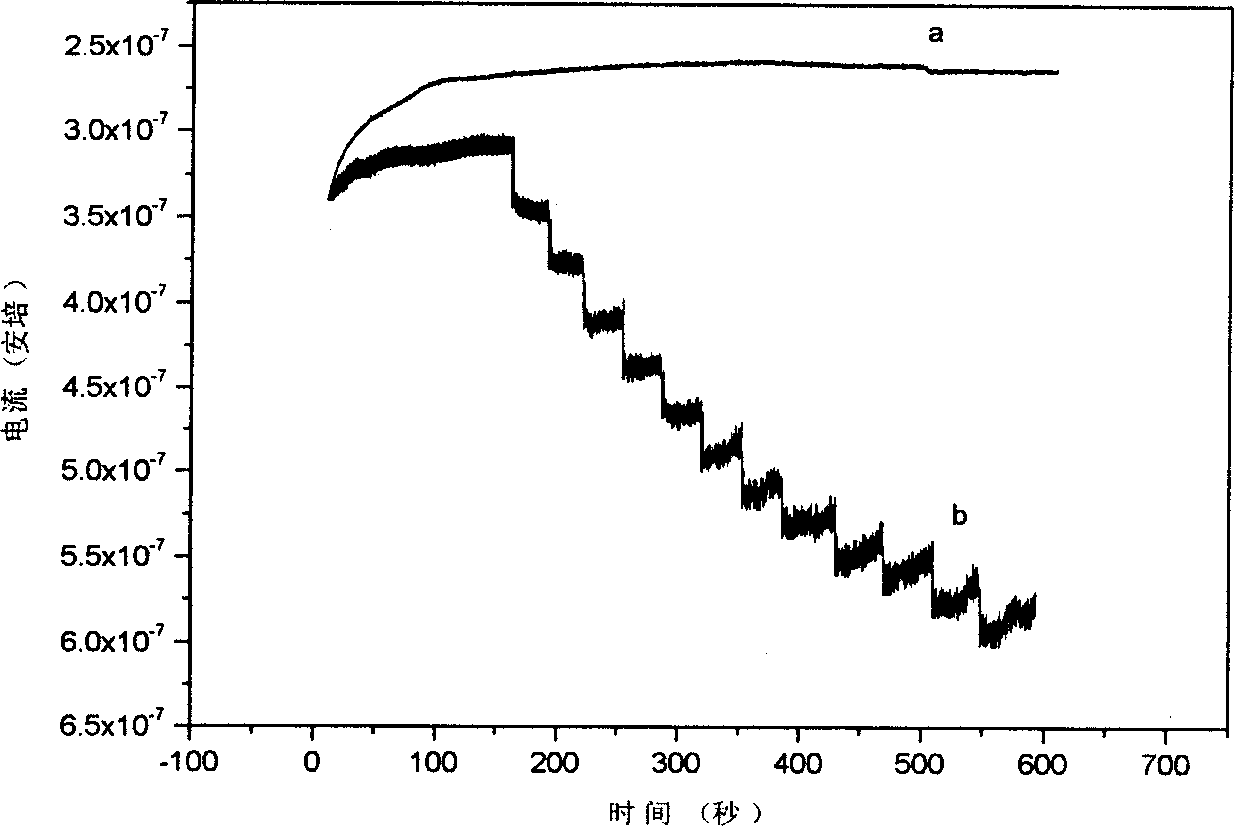

[0017] Embodiment 1: immobilized xanthine oxidase and its preparation: Commercialized single-walled carbon nanotubes were refluxed with 68% concentrated nitric acid for 16 hours to carry out open-tube oxidation (Nature 372 (1994) 159-162), and washed with water to medium and dry it, take 1 mg of the obtained single-walled carbon nanotubes and 1 mg of dihexadecyl phosphoric acid, add them to 1 ml of distilled water, and ultrasonically disperse them for 10 hours to obtain stable single-walled carbon nanotubes - dihexadecane phosphoric acid dispersion. Add 2 microliters of the obtained dispersion solution dropwise on the polished glassy carbon electrode, place it under an infrared lamp, and wait for the solvent to volatilize completely to obtain a glassy carbon electrode modified by a single-walled carbon nanotube-dicetyl phosphoric acid mixed film. In the potential range of -1.0 volts to 1.5 volts, the electrochemical workstation was scanned cyclically at a scan rate of 500 mV / s...

Embodiment 2

[0020] Example 2: immobilized xanthine oxidase and its preparation: commercialized multi-walled carbon nanotubes were refluxed with 68% concentrated nitric acid for 16 hours to carry out open-tube oxidation (Nature 372 (1994) 159-162), and washed with water to medium properties and drying, take 0.5 mg of the resulting multi-walled carbon nanotubes and 0.6 mg of dihexadecyl phosphoric acid, add to 0.5 ml of distilled water, and ultrasonically disperse for 10 hours to obtain stable multi-walled carbon nanotubes - dihexadecane phosphoric acid dispersion. Add 2 microliters of the obtained dispersion solution dropwise on the polished glassy carbon electrode, place it under an infrared lamp, and wait for the solvent to volatilize completely to obtain a glassy carbon electrode modified by a multi-walled carbon nanotube-dicetyl phosphate mixed film. In the potential range of -1.0 volts to 1.5 volts, the electrochemical workstation was scanned 30 times at a scan rate of 100 mV / s to obt...

Embodiment 3

[0023]Example 3: immobilized xanthine oxidase and its preparation: Commercialized single-walled carbon nanotubes were refluxed with 68% concentrated nitric acid for 16 hours to carry out open-tube oxidation (Nature 372 (1994) 159-162), and washed with water to medium and dried, take 2 mg of the obtained single-walled carbon nanotubes and 1.7 mg of dihexadecyl phosphoric acid, add them to 1 ml of distilled water, and ultrasonically disperse them for 10 hours to obtain stable single-walled carbon nanotubes - dihexadecane phosphoric acid dispersion. Add 2 microliters of the obtained dispersion solution dropwise on the polished glassy carbon electrode, place it under an infrared lamp, and wait for the solvent to volatilize completely to obtain a glassy carbon electrode modified by a single-walled carbon nanotube-dicetyl phosphoric acid mixed film. In the potential range of -1.0 volts to 1.5 volts, the electrochemical workstation was cycle-scanned at a scan rate of 500 mV / s for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com