Local heat treatment residual heat stress control method of spherical vessel

A technology of residual thermal stress and local heat treatment, which is applied in the field of heat treatment, can solve problems such as the inability to guarantee the effect of heat treatment, and achieve the effects of avoiding stress corrosion cracking and brittle fracture, safe and convenient operation, and increasing safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

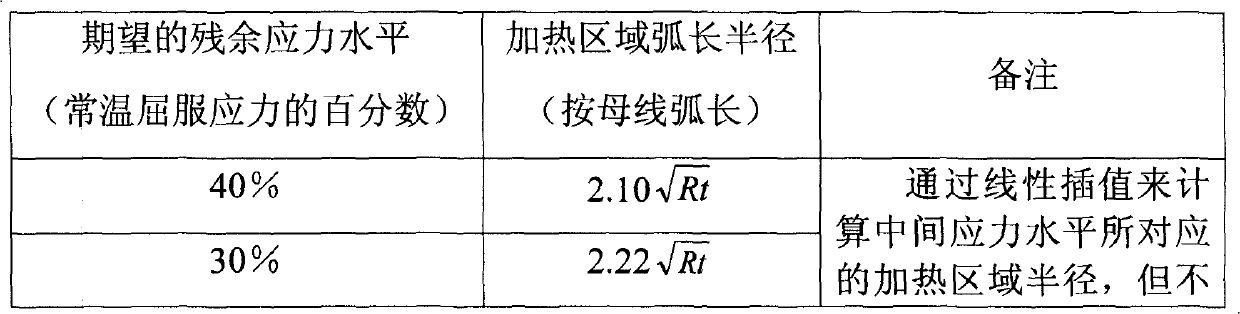

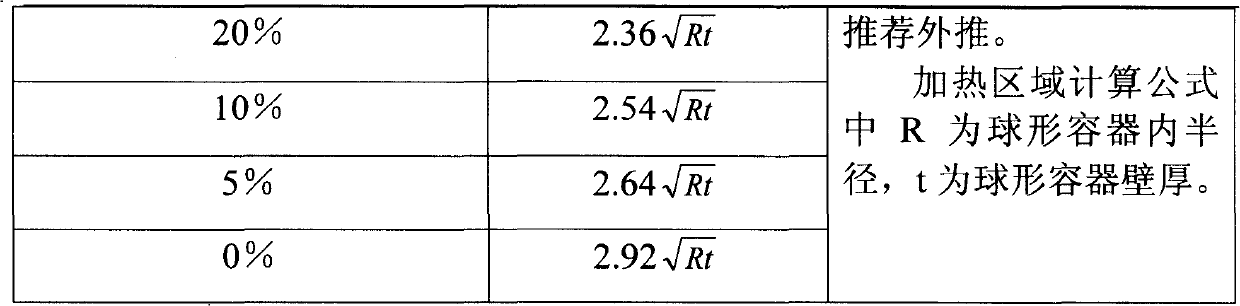

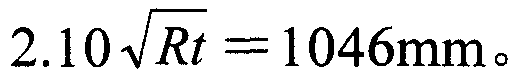

[0013] The present invention will be further described in detail below in conjunction with specific embodiments: A method for controlling the residual thermal stress of a spherical container in local heat treatment, firstly calculate the area of the circular heating area according to the volume of the spherical container, the wall thickness and the area of the treated area required for local heat treatment. arc length radius, place the selected heating appliance on the area to be treated for heating. Can be heated on one side or on both sides. When the inner single-sided heating is used, the corresponding outer surface should be provided with an insulating layer; when the outer single-sided heating is used, the corresponding inner surface should be provided with an insulating layer. However, regardless of single-sided heating or double-sided heating, the surface of the heating appliance in contact with the air should be reliably insulated. The heating surface is circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com