Environment protection elastic metallic plastic bush

An elastic metal, environmentally friendly technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of uneven contact pressure, high cost, complex product structure, etc., to reduce costs, wear resistance and mechanical properties. The effect of improved performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] a. Using existing technology to make wire mats;

[0013] b. Mix the aramid fibers accounting for 2-8% of the total weight, polyphenylene ester or polyimide accounting for 20-30% of the total weight, and the rest of polytetrafluoroethylene, and put the raw materials into the cylinder for mixing In the machine, select the rotating speed of 100~150r, and mix for 20~50 minutes;

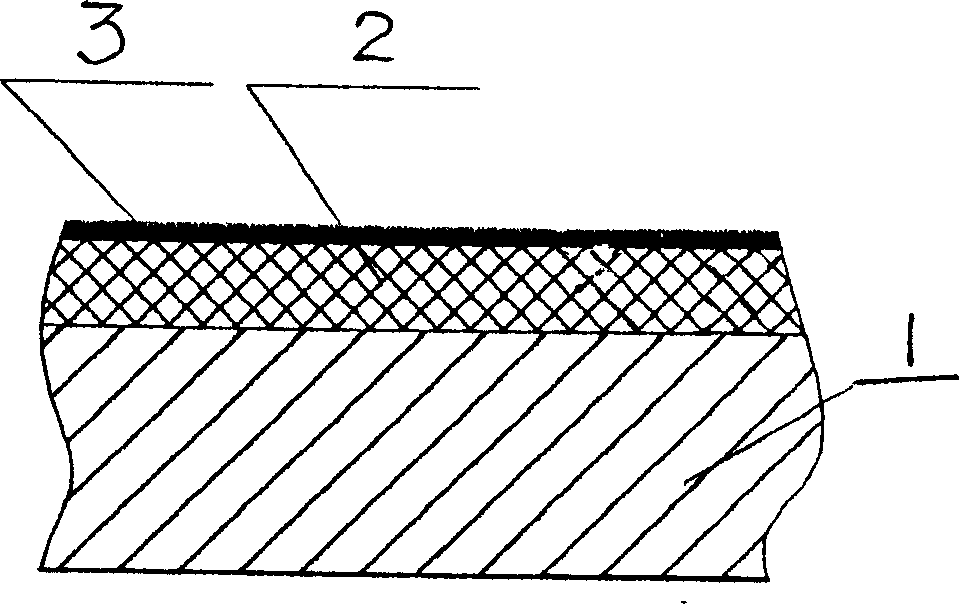

[0014] c. Sprinkle the mixed powder on the metal wire elastic pad 2 blank, and mold and compound it into a tile surface blank according to the conventional method;

[0015] d. Sinter the tile surface blank according to the conventional method to make a tile surface with a surface plastic layer 3 embedded on the wire elastic pad 2;

[0016] e. The tile surface is brazed on the steel tile base 1, that is, it is made as figure 1 product shown.

Embodiment 2

[0018] Others are the same as in embodiment 1, except that the aramid fiber accounts for 3-4% of the total weight, polyphenylene ester or polyimide accounts for 23-26% of the total weight, and the balance is polytetrafluoroethylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com