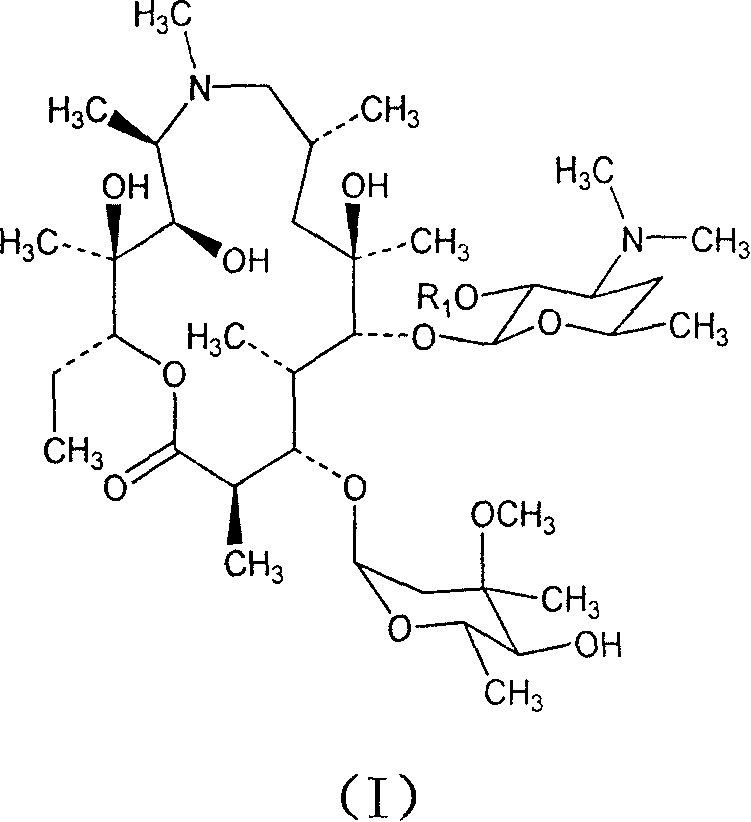

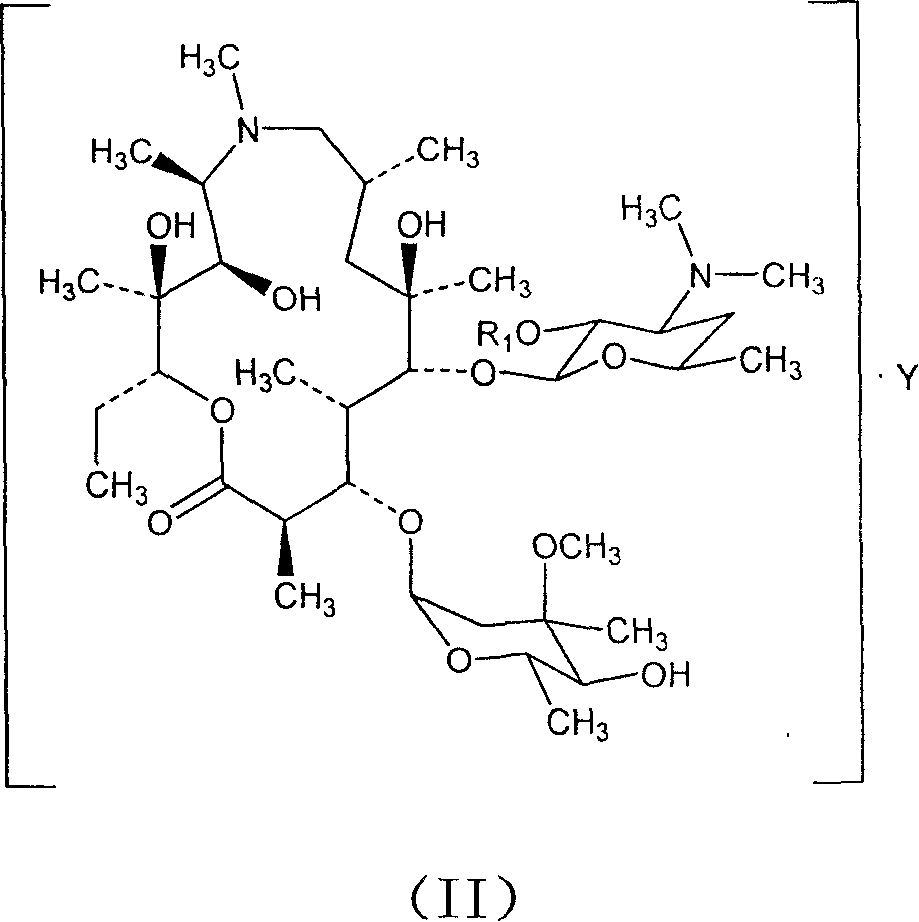

Azithromycin derivatives and its preparation process and pharmaceutical application

A technology of azithromycin and derivatives, applied in the field of macrolide drugs, can solve problems such as azithromycin taste bitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

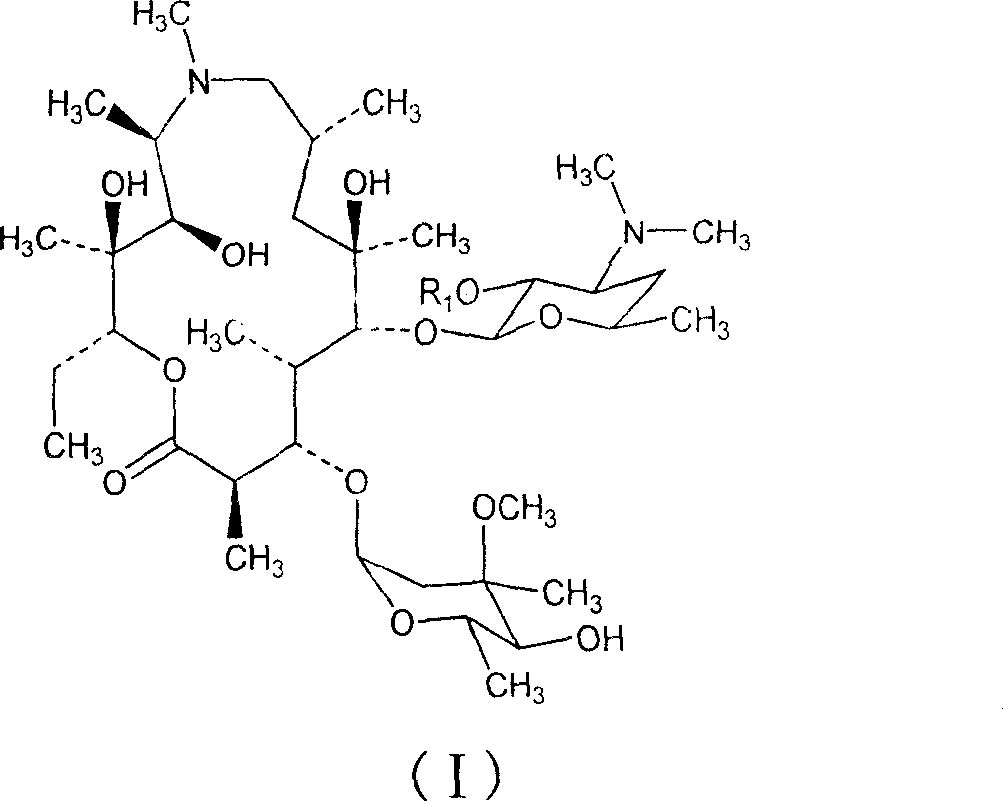

[0110] Example 1 Azithromycin-2'-propionate

[0111] method one

[0112] Azithromycin 6.0g, dissolved in 20ml THF, 4.8g K 2 CO 3 A solution made of 22ml of water was added, the mixture was stirred and cooled to 5-10°C, 5.0g of propionyl chloride was added over 40 minutes, stirred in an ice bath for 30 minutes, and then stirred overnight at room temperature. Add 0.3g of sodium citrate, use NaOH solution to adjust the pH value of the reaction aqueous solution between 8.0-9.0, and stir for half an hour, the solution is layered, take the organic layer, concentrate to obtain a white solid, add ether to dissolve the solid, and heat Wash, cool and filter, and dry the filter cake in an oven at 30-40°C. The weight of the white solid is 5.2 g, and the yield is 81.0%.

[0113] Method Two

[0114] Dissolve 6.0 g of azithromycin in 30 ml of THF with stirring, add 5.0 g of propionic acid, dropwise add 1.0 ml of dimethyl sulfoxide, stir for 7 hours, adjust the pH value of the reaction a...

example 2

[0119] Example 2 Azithromycin-2'-ethylsuccinate

[0120] method one

[0121] Azithromycin 6.0g, dissolved in 20ml THF, 4.8g K 2 CO 3 A solution made of 22ml of water was added, the mixture was stirred and cooled to 5-10°C, 3.7g of succinic monoethyl chloride was added over 40 minutes, stirred in an ice bath for 30 minutes, and then stirred at room temperature for 24 Hour. Add 0.3g of sodium citrate, adjust the pH value of the reaction aqueous solution between 9.0-9.5 with NaOH solution, and stir for half an hour, the solution is layered, the organic layer is taken, concentrated to obtain 6.0g of white waxy solid, the yield 86%.

[0122] Method Two

[0123] Dissolve 6.0g of azithromycin in 30ml of THF with stirring, add 4.0g of monoethyl succinate, dropwise add 1.0ml of dimethyl sulfoxide, stir and react for 7h, adjust the pH value of the reaction aqueous solution between 8.0-9.0 with NaOH solution Then, about 40ml of water was added to precipitate a solid, which was filt...

example 3

[0126] Example 3 Azithromycin-2'-isobutyrate

[0127] method one

[0128] Azithromycin 6.0g, dissolved in 20ml THF, 4.8g K 2 CO 3 A solution made of 22ml of water was added, the mixture was stirred and cooled to 5-10°C, 5.0g of isobutyryl chloride was added over 40 minutes, stirred in an ice bath for 30 minutes, and then stirred overnight at room temperature. Add 0.3g of sodium citrate, use NaOH solution to adjust the pH value of the reaction aqueous solution between 8.0-9.0, and stir for half an hour, the solution is layered, take the organic layer, concentrate to obtain a white solid, add ether to dissolve the solid, and heat Wash, cool and filter, and dry the filter cake in an oven at 30-40°C. The weight of the white solid is 5.0 g, and the yield is 76.5%.

[0129] Method Two

[0130] Dissolve 6.0g of azithromycin in 30ml of THF with stirring, add 5.0g of isobutyric anhydride, dropwise add 0.5ml of concentrated sulfuric acid, stir for 3 hours, then add about 40ml of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com