Cuttlebone polysaccharide CPS-1 and its preparation and use

A technology of CPS-1 and squid octopus, which is applied in the field of medicine, can solve the problems of no polysaccharide components and undetermined active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

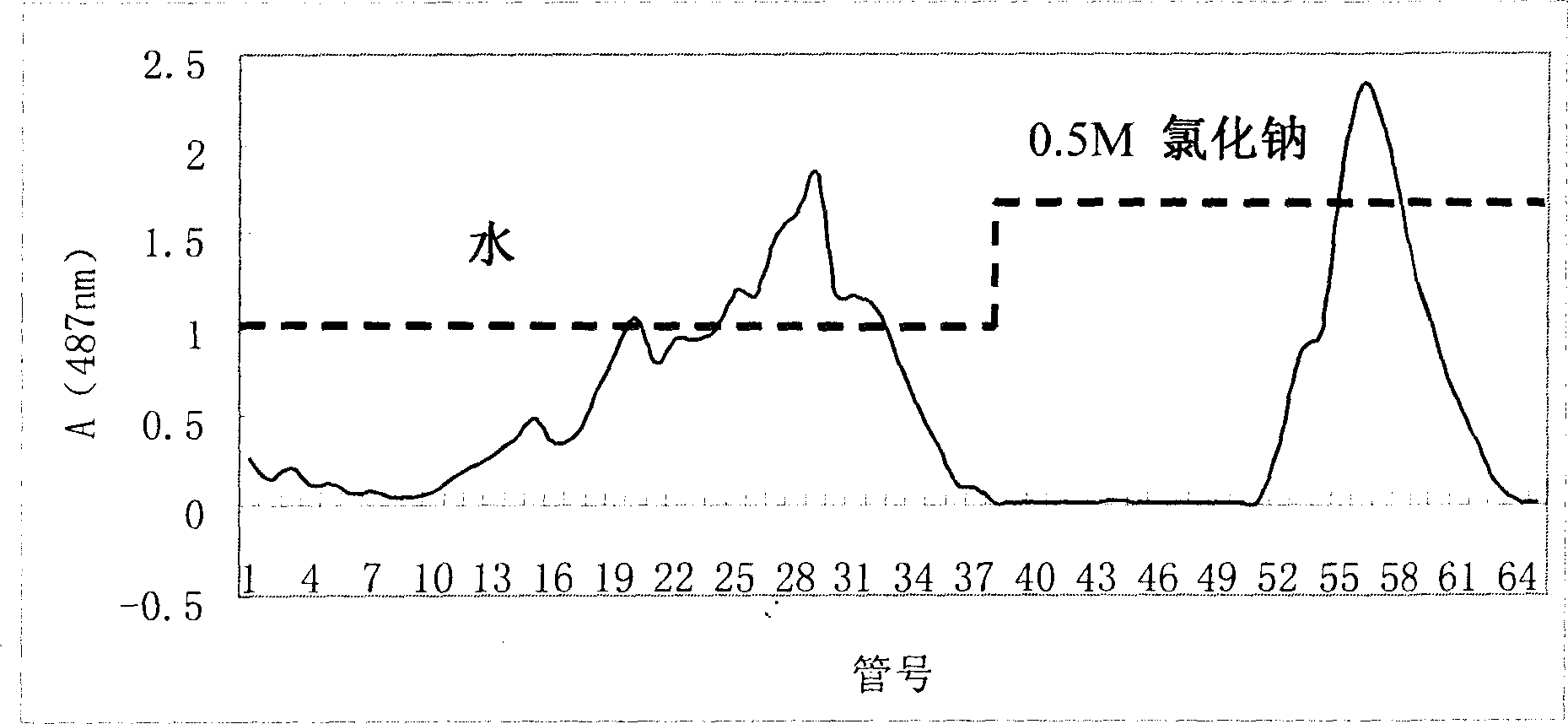

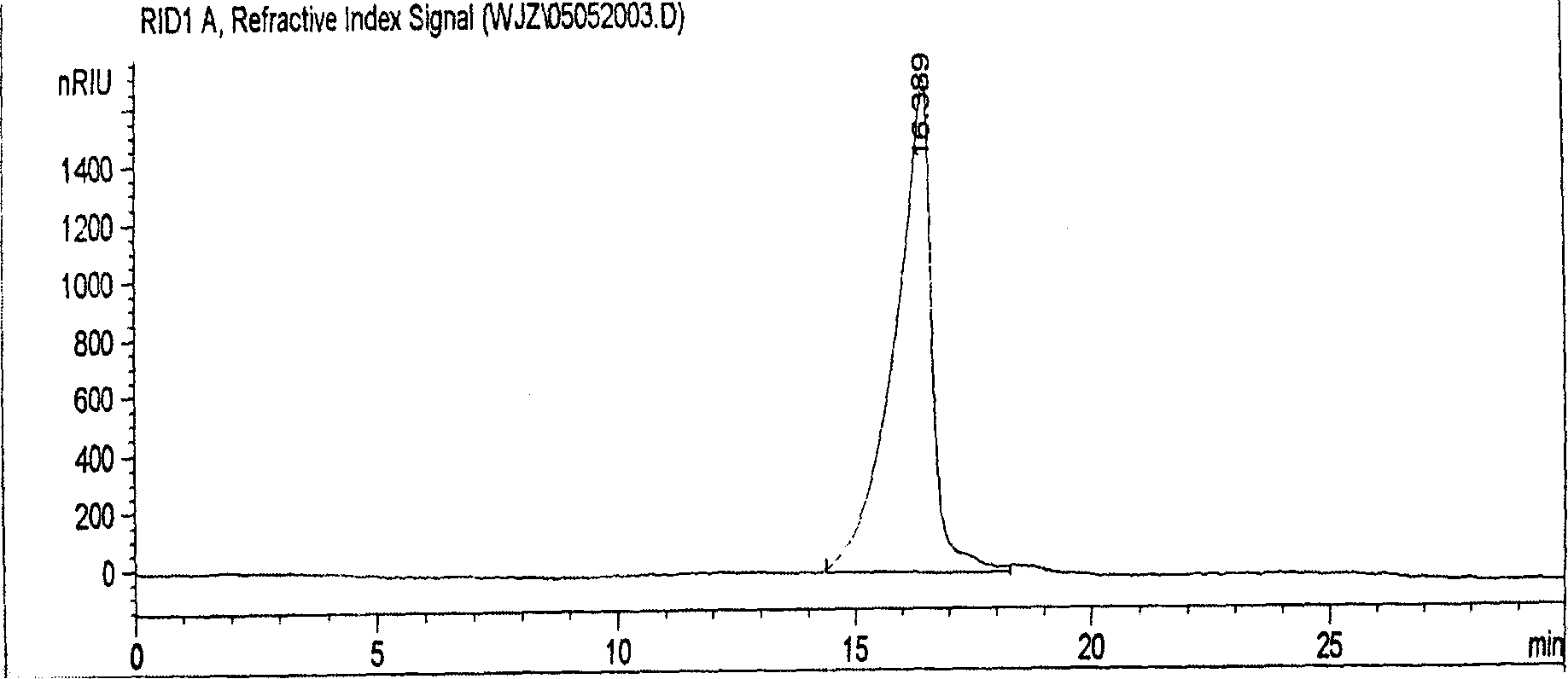

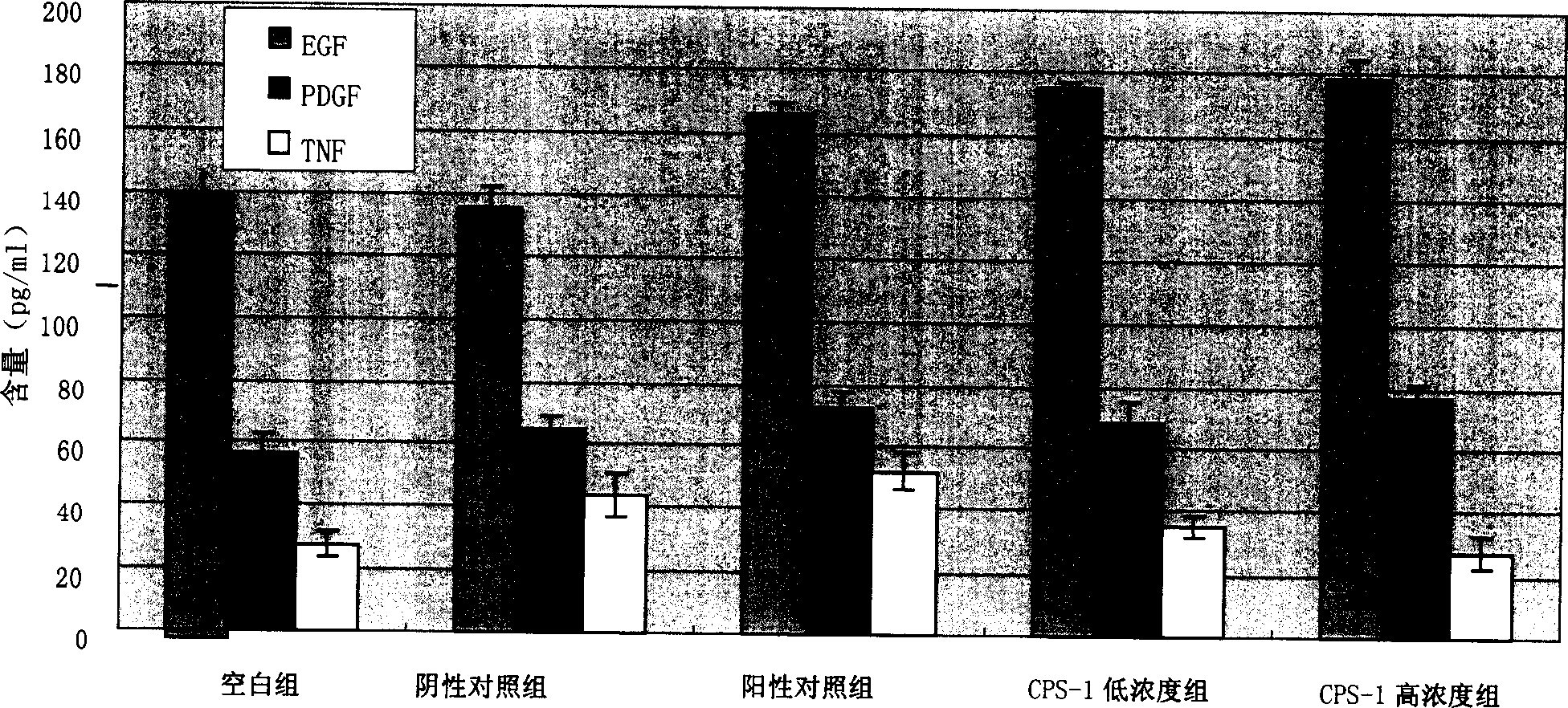

[0025] Example 1: Preparation of seaweed octopus polysaccharide CPS-1

[0026] (1) Preparation of Crude Polysaccharides from Sea Cuttlefish

[0027] Crush 5kg of sea octopus for 3 minutes, add 16L of water and cook for 10 hours, filter with gauze while it is hot, repeat the extraction of the residue twice, combine the water extracts for 3 times, concentrate to 12L with a rotary evaporator, centrifuge at 5000rpm for 10 minutes, and discard the precipitate. The supernatant was extracted three times by sevage method with a volume ratio of chloroform and n-butanol of 4:1 to remove protein, until the aqueous phase was free of protein, and then added 3 times the volume of ethanol to ethanol precipitation overnight. Discard the supernatant by centrifugation, redissolve the precipitate in distilled water, centrifuge at 5000rpm for 10 minutes, discard the insoluble matter, and precipitate the supernatant with ethanol for the second time, centrifuge to remove the supernatant, dissolve t...

Embodiment 2

[0038] Example 2: Preparation of seaweed octopus polysaccharide CPS-1

[0039]Crush 5kg of sea octopus for 5 minutes, add 12L of water and cook for 9 hours, filter with gauze while it is hot, repeat the extraction of the residue twice, combine the water extracts for 3 times, concentrate to 12L with a rotary evaporator, centrifuge at 5000rpm for 10 minutes, and discard the precipitate. The supernatant was extracted three times by sevage method with a volume ratio of chloroform and n-butanol of 4:1 to remove protein until the aqueous phase was free of protein, and then added 3 times the volume of ethanol to ethanol precipitation overnight. Discard the supernatant by centrifugation, redissolve the precipitate in distilled water, centrifuge at 5000rpm for 10 minutes, discard the insoluble matter, and precipitate the supernatant with ethanol for the second time, centrifuge to remove the supernatant, dissolve the precipitate in distilled water, and dialyze in running water for 40 hou...

Embodiment 3

[0041] Example 3: Preparation of seaweed octopus polysaccharide CPS-1

[0042] Crush 5kg of sea octopus for 8 minutes, add 14L of water and cook for 14 hours, filter with gauze while it is hot, repeat the extraction of the residue twice, combine the water extracts for 3 times, concentrate to 12L with a rotary evaporator, centrifuge at 5000rpm for 10 minutes, and discard the precipitate. The supernatant was extracted three times by sevage method with a volume ratio of chloroform and n-butanol of 4:1 to remove protein until the aqueous phase was free of protein, and then added 3 times the volume of ethanol to ethanol precipitation overnight. Discard the supernatant by centrifugation, redissolve the precipitate in distilled water, then centrifuge at 5000rpm for 10 minutes, discard the insoluble matter, and precipitate the supernatant with ethanol for the second time, centrifuge to remove the supernatant, dissolve the precipitate in distilled water, and dialyze in running water for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com