Broadband single-polarization single-mode dual-core photonic crystal fiber

A photonic crystal fiber, single-polarization technology, used in cladding fibers, optical waveguides, light guides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

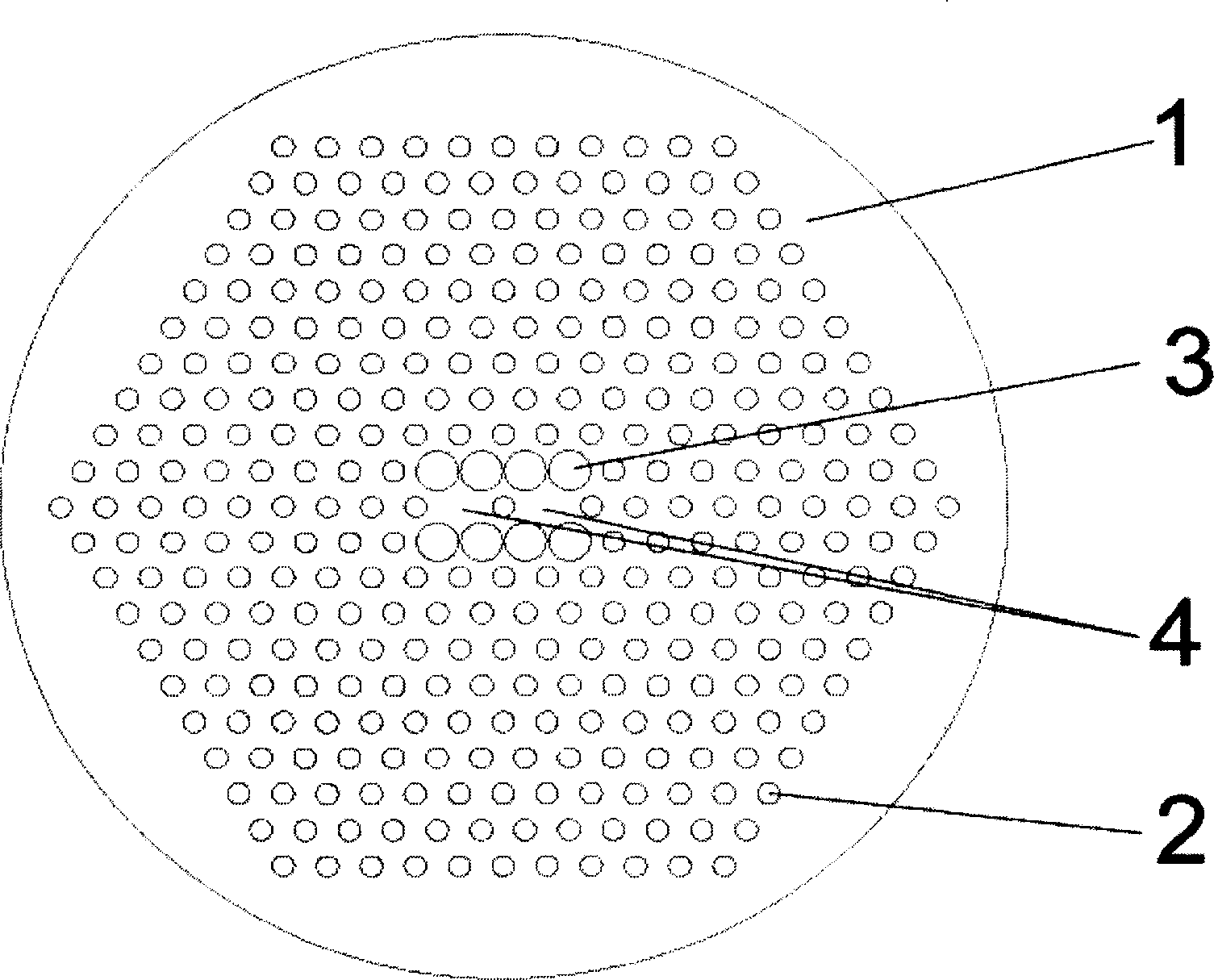

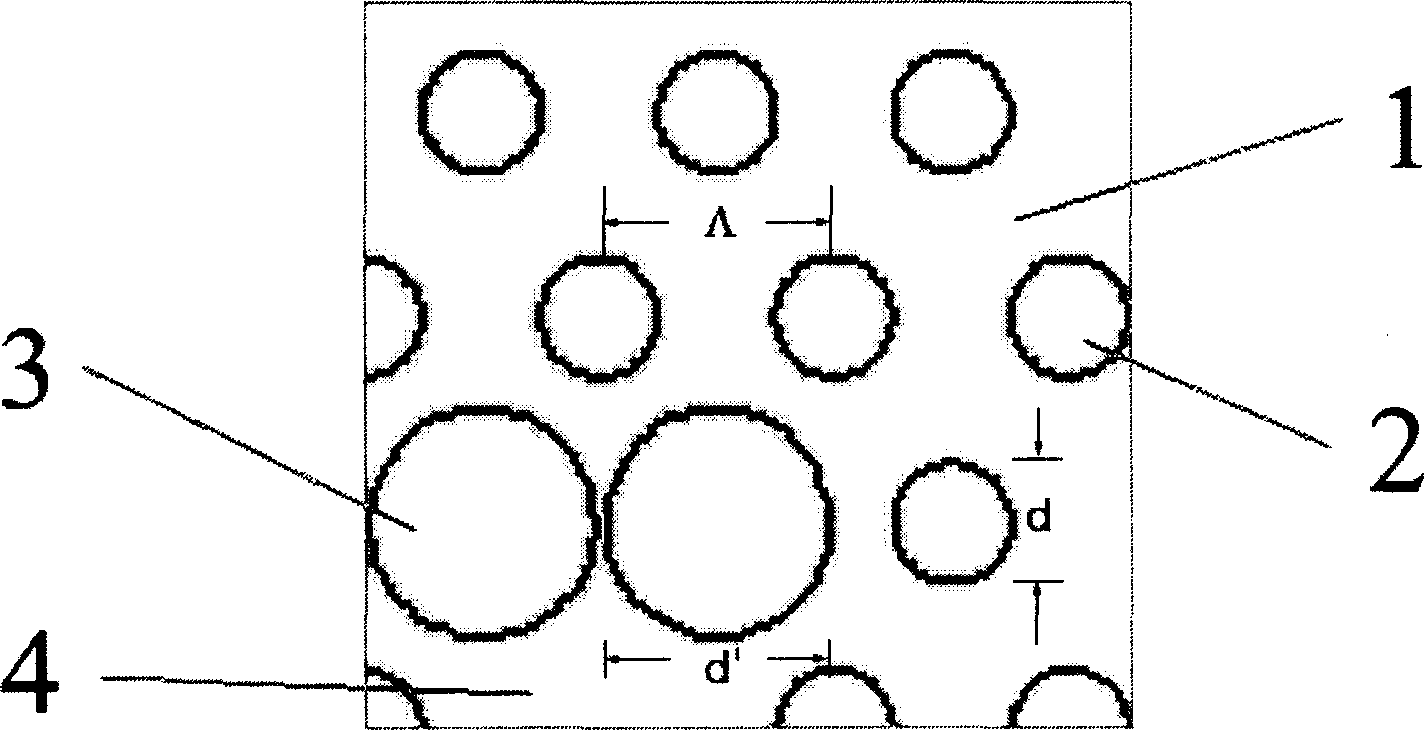

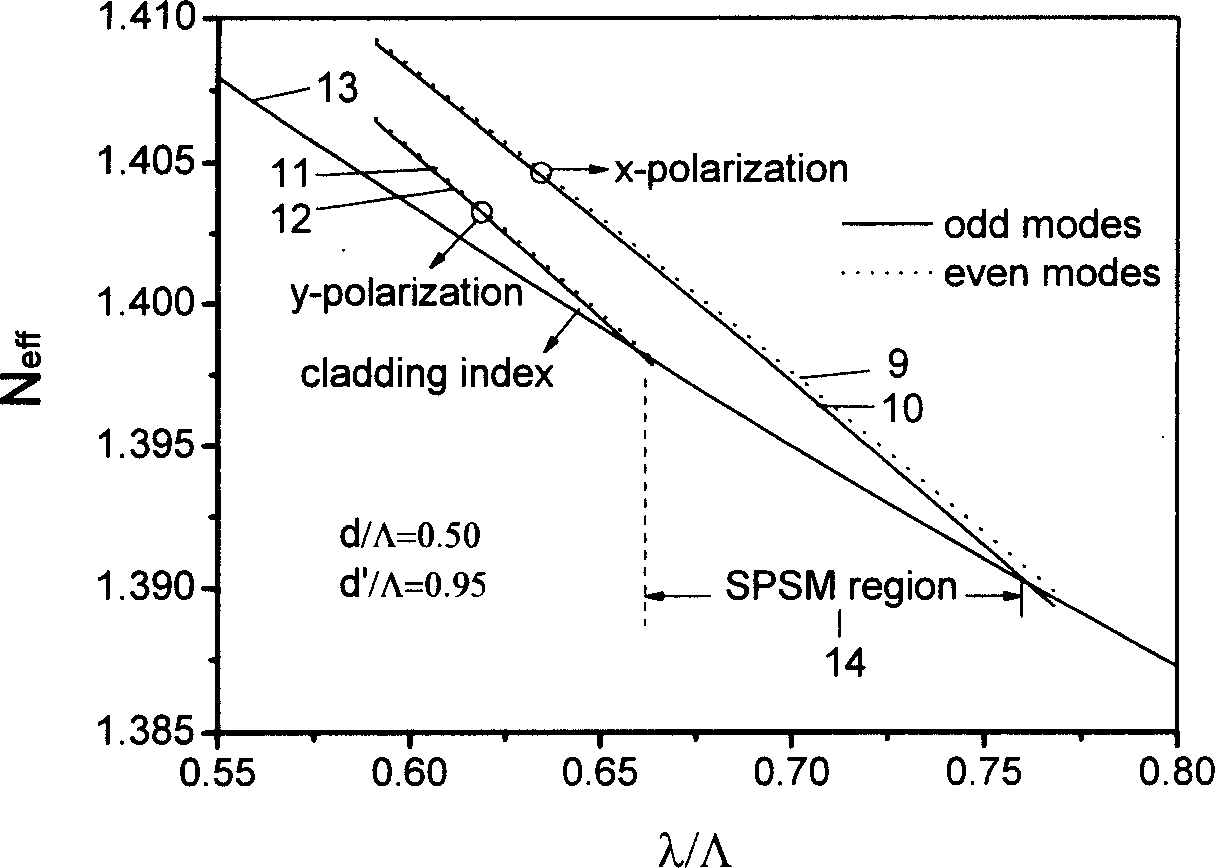

[0022] The cladding of this broadband single-polarization single-mode dual-core photonic crystal fiber is formed by arranging air holes 2 and 3 in a regular network structure on the substrate, and two defect cores 4 are formed by the absence of cladding air holes, which are characterized in that : The sizes of the air holes near the two core regions are different in the two orthogonal polarization directions of the fiber cross-section, and the above-mentioned cross-sectional structure is constant along the length direction of the fiber.

[0023]The air holes in the fiber cladding are arranged in a triangular grid, and the two defect cores are located at the nodes of the triangular grid.

[0024] The air hole in the cladding layer and the defect core on the cross section of the fiber can be circular, and the diameter of the hole in the X direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com