Functional transition metal silicates (FTMS)

A metal silicate and transition metal technology, applied in the direction of non-metallic elements, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as no research on copper silicate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

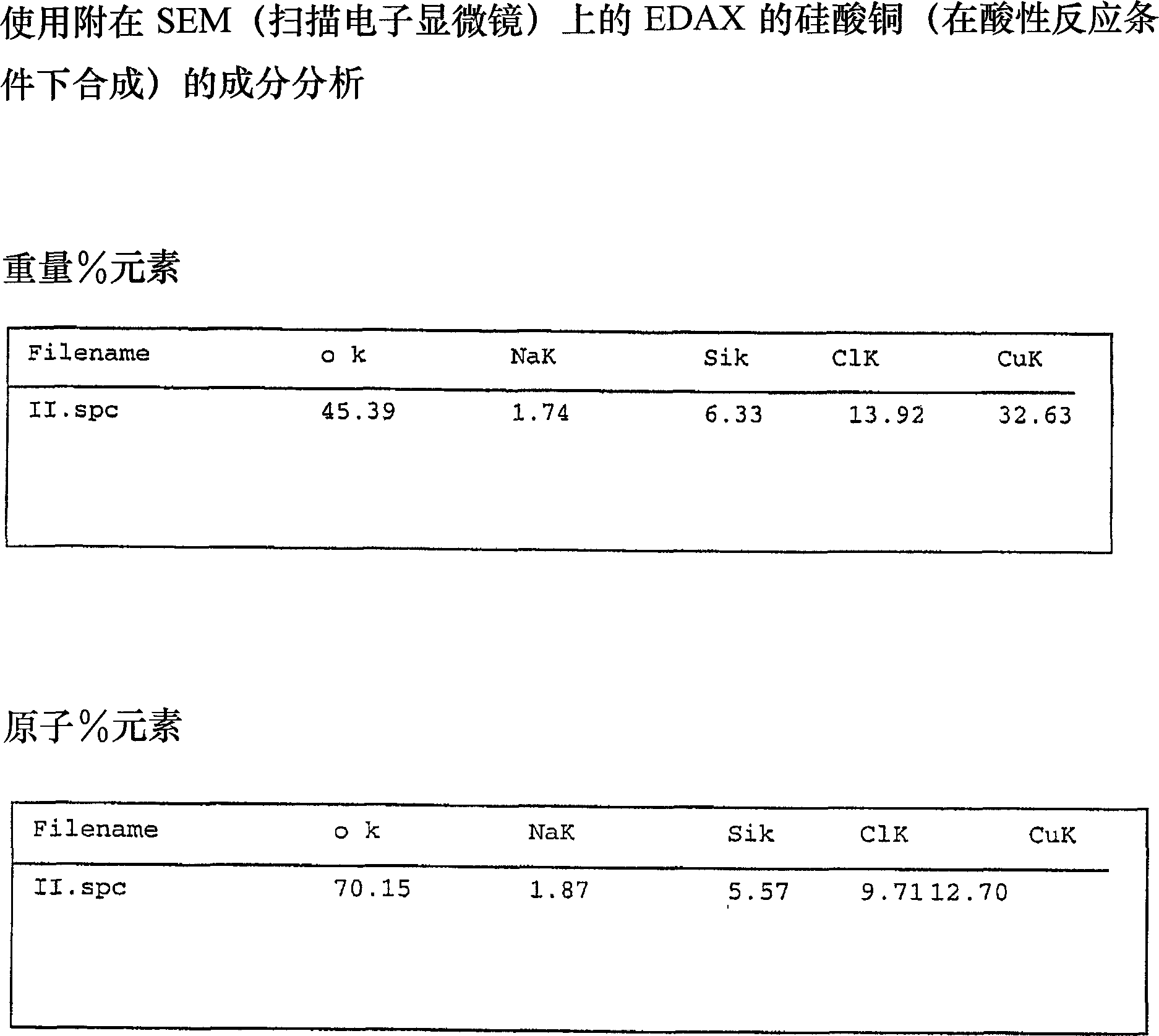

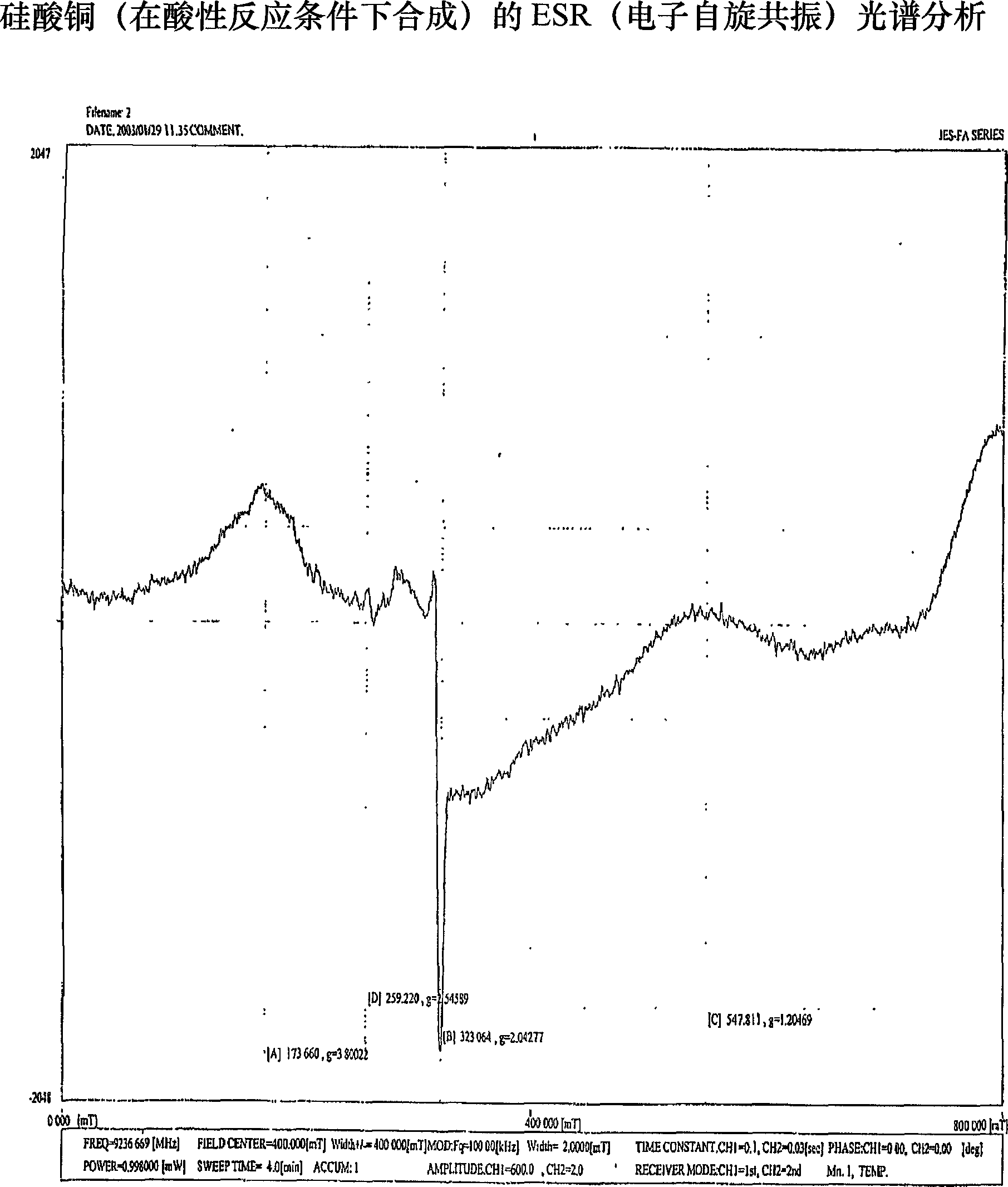

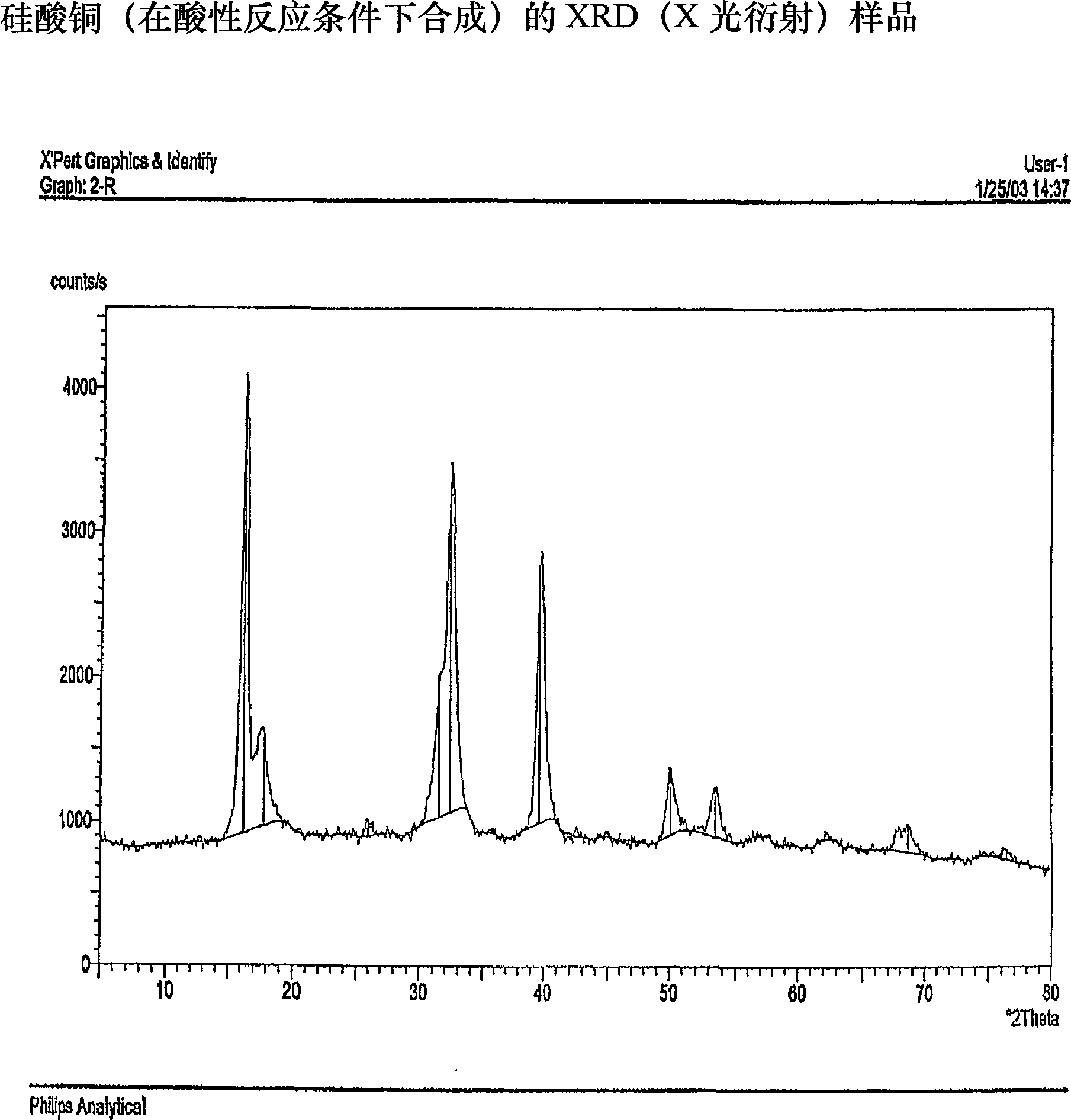

[0368] Analyze functional transition metal silicates through SEM / EDAX (ESEM, XL-30), ESR (JEOL, JES-FA-200), and XRD (PHILIPS, PW-1830) to understand the composition, structure and other details.

[0369] The applicant now provides the following detailed description of the present invention in the form of examples and illustrations, which should not be construed as limiting the scope of the present invention in any way.

[0370] Synthesis of Copper Silicate

[0371] The synthesis of copper silicate will be described in detail with the following example.

[0372] 1. Synthesis of copper silicate under acidic reaction conditions:

[0373] 10ml sodium silicate / sodium ratio 2:1 sodium silicate solution (0.5g / ml) was added to 100ml copper chloride solution (Cucl 2 2H 2 O, 0.5g / ml). The reaction conditions are acidic.

[0374] The final precipitate obtained after removing the supernatant is thoroughly washed with distilled water or deionized water and then dried.

[0375] Analyze copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com