Method of producing a colour display device and colour display device

An equipment and liquid crystal display technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of increasing final products, time-consuming batch processes, complexity, etc., and achieve the effect of improving efficiency and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

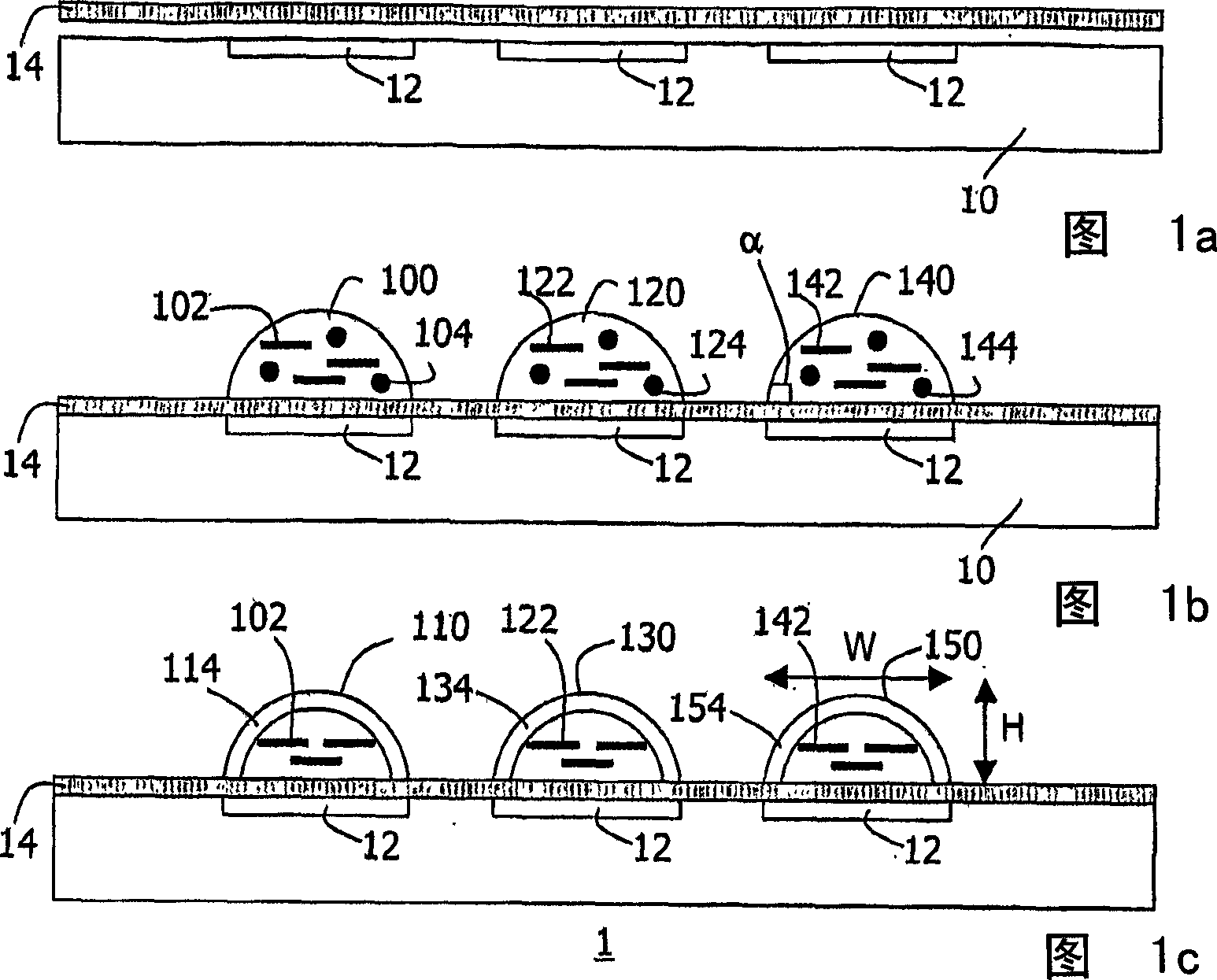

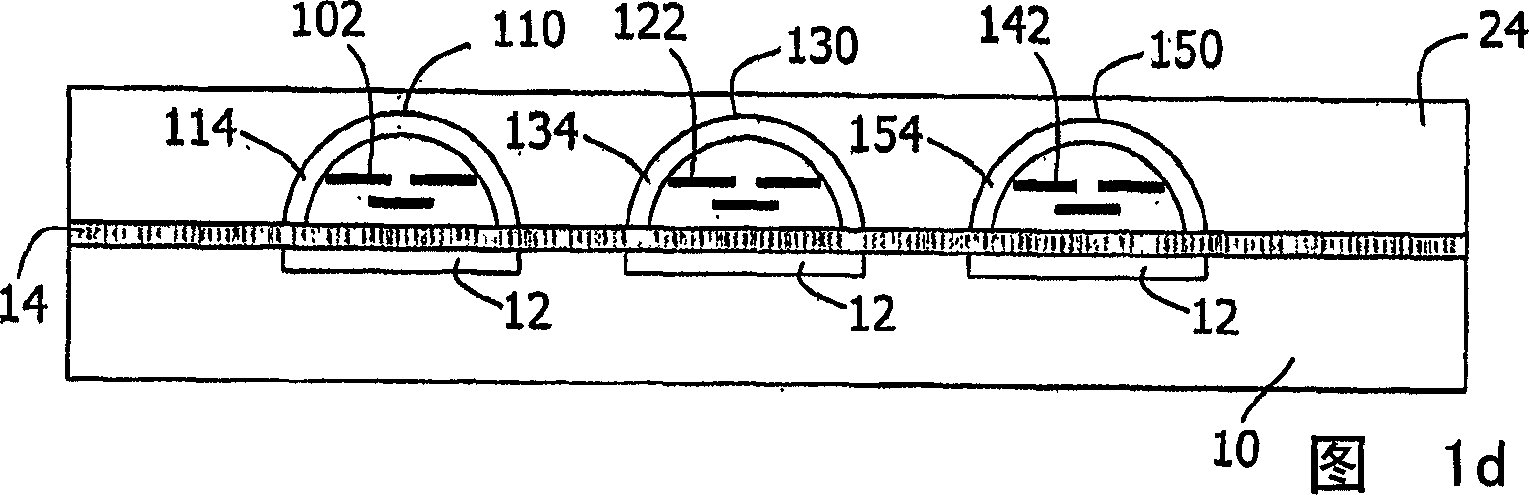

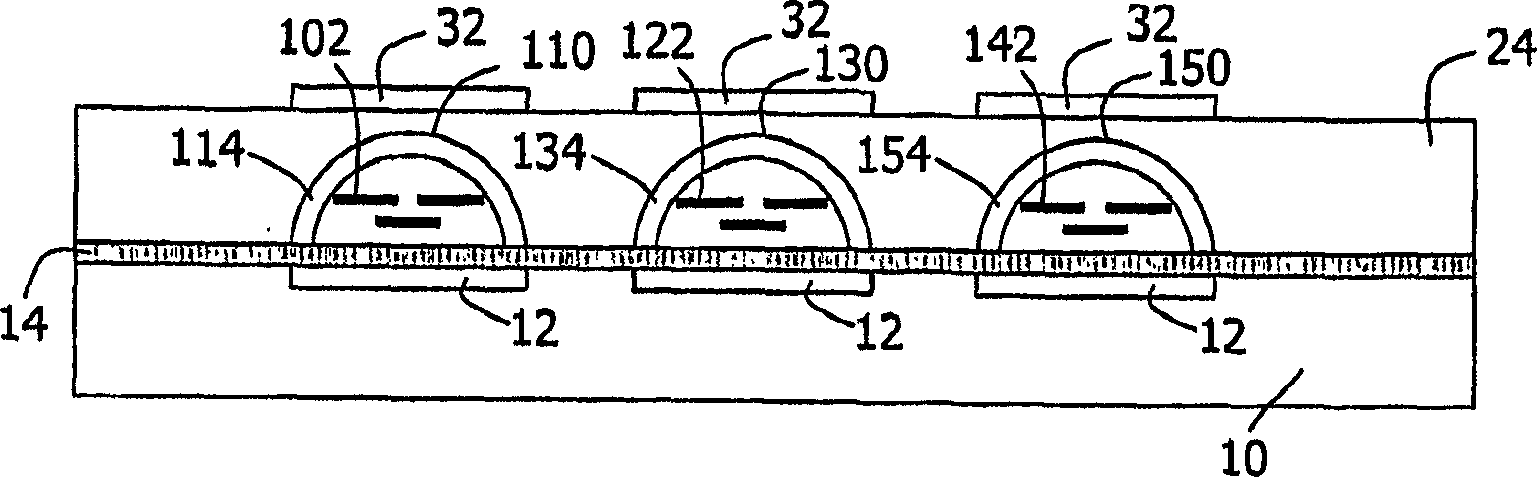

[0030] It should be understood that the drawings are only schematic and not drawn to scale. It should also be understood that throughout the drawings, the same reference numerals are used to designate the same or similar parts.

[0031] FIG. 1 a shows a carrier 10 including an optional electrode structure 12 . It should be emphasized that Figure 1 and the following figures show an embedded electrode structure 12 for reasons of clarity only. It should be understood that the surface of the carrier 10 is preferably also defined by the arrangement of the electrode structures 12 on top of the carrier 10 . The electrode structure 12 may be formed from a known material, such as indium tin oxide (ITO), on top of the carrier 10 by known techniques for forming electrode structures on the carrier 10 . The carrier 10 may comprise any suitable material, such as glass, polymers, or even non-obvious materials such as modified wood, ceramic or modified paper.

[0032] Optionally, the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com