Wafer laser processing method and laser processing device

A laser processing method and chip technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that it is difficult to uniformly cover liquid resin, difficult to cover resin protective film, etc., and achieve uniform laser processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, best embodiments of the laser processing method and laser processing apparatus for a wafer using the present invention will be described in detail with reference to the accompanying drawings.

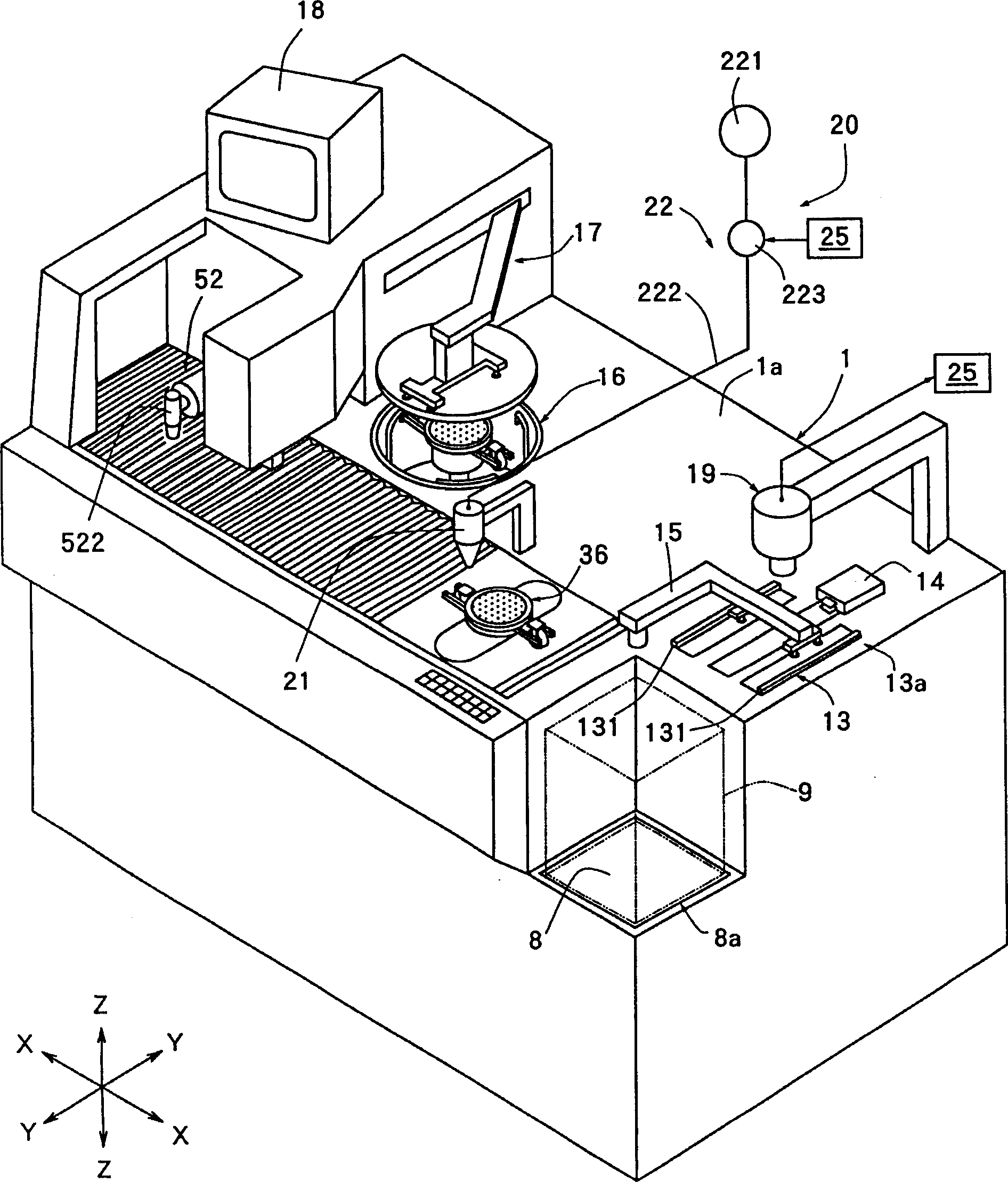

[0031] figure 1 It is a perspective view of a laser processing apparatus according to the present invention, which has a protective film forming and cleaning mechanism for implementing the protective film coating method of the present invention.

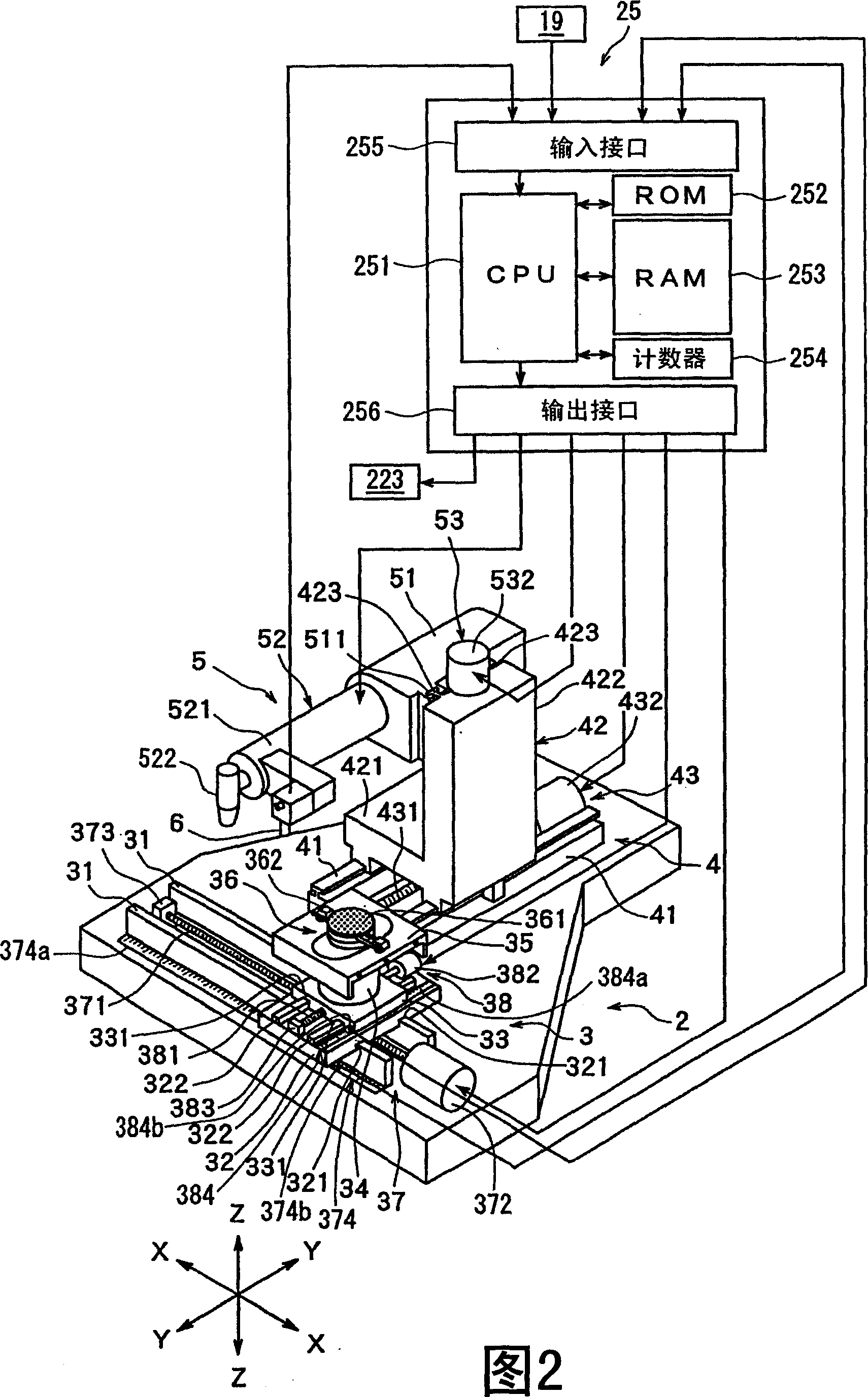

[0032] figure 1 The laser processing device shown has an approximately cuboid-shaped device housing 1 . Arranged in this device shell 1: the stationary base 2 shown in Fig. 2; It has a chuck table for holding the processed object; the laser beam irradiation unit support mechanism 4 is arranged on the stationary base 2, and can be in the direction shown by the arrow Y as the indexing feed direction ( Move in the direction perpendicular to the direction shown by the arrow X as the processing feed direction); and the lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com