Steel for low temperature and high tenacity structure use and its production method

A technology for structural steel and manufacturing methods, which is applied in the field of structural steel, can solve problems such as high cost and complicated processing technology, and achieve the effects of increasing manufacturing cost, reducing production cost, and shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

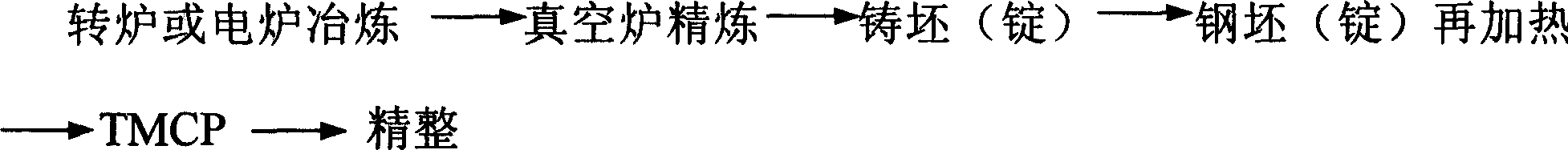

Method used

Image

Examples

Embodiment Construction

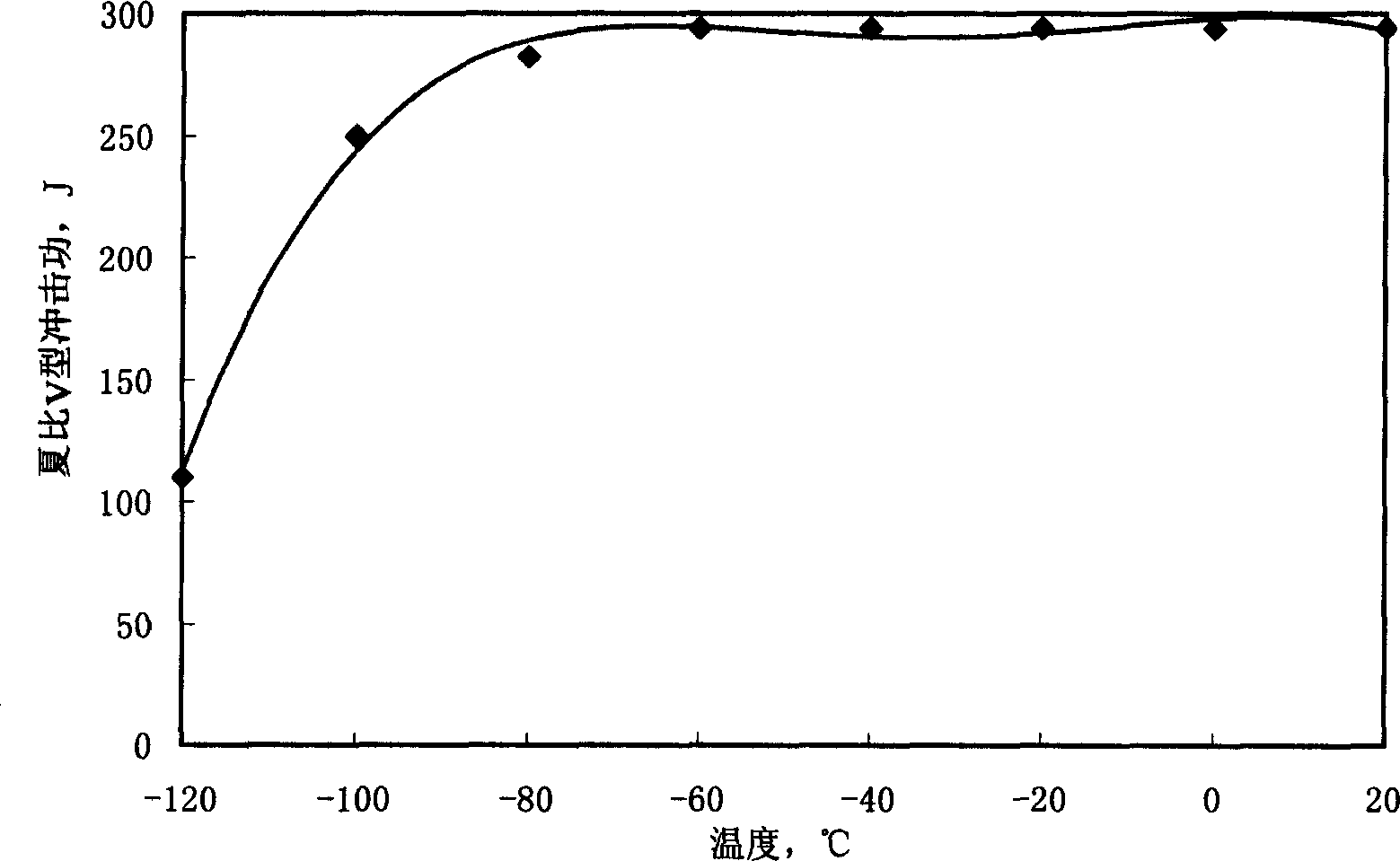

[0037] Examples see figure 1 ,Table 2.

[0038] The steel type designed by the present invention does not need to add elements such as above precious Ni, Cr or Mo, only needs to slightly increase very cheap Si (extremely cheap. Solid solution strengthening, reduces bainite transformation point, and makes bainite C The curve moves to the right, inhibits the decomposition of supercooled austenite, increases the volume fraction of retained austenite and stabilizes austenite, promotes the formation of carbon-rich austenite film between ferrite in bainite, and improves toughness), Mn (Cheap. Strongly reduce bainite point, weakly reduce martensite point, improve hardenability and strength) and trace amounts of Nb and Ti (Nb and Ti are microalloying elements, which can control the growth of grains by precipitation Large, improve strength) and other elements and a certain controlled rolling and controlled cooling process (TMCP), can meet the requirements of better strength and toughn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com