Release film

A technology for peeling off film and base materials, which is applied in capacitor manufacturing, fixed capacitance parts, laminated capacitors, etc., which can solve the problems of slurry repelling, static electricity generation, and small hole formation, and achieve the effect of preventing adhesion and static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

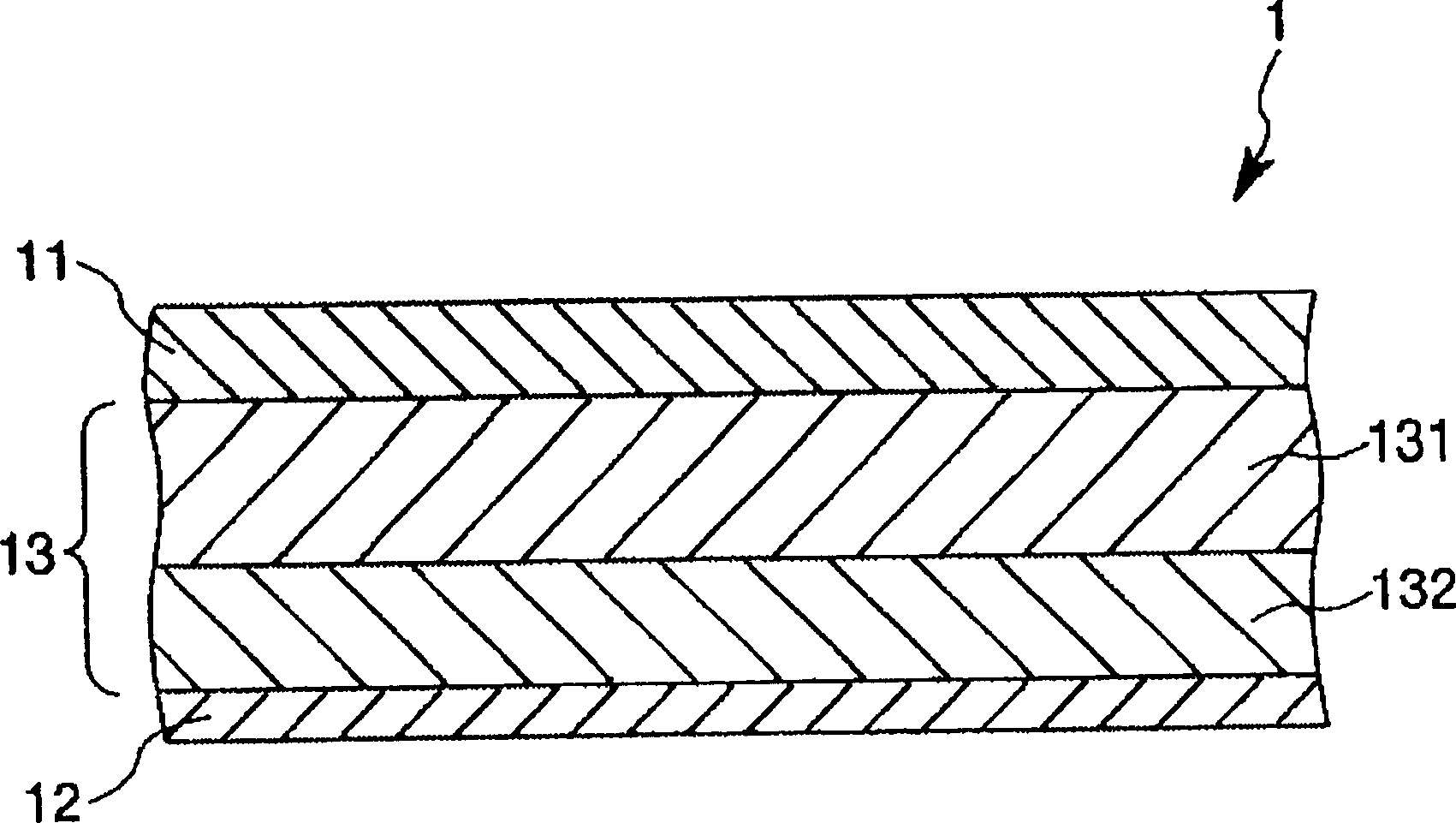

[0071] First, a substrate composed of a first substrate layer and a second substrate layer both made of polyethylene terephthalate (PET) was formed by a co-extrusion method. The surface roughness Ra of the outer surface of the first base material layer was 5 nm and the thickness of the first base material layer was 6 μm. On the other hand, the surface roughness Ra of the outer surface of the second base material layer was 20 nm and the thickness of the second base material layer was 32 μm.

[0072] Furthermore, 100 parts by weight of a silicone resin ("KS847H", manufactured by Shin-Etsu Chemical Co., Ltd.) and 1 part by weight of a curing agent ("CAT-PL5OT", manufactured by Shin-Etsu Chemical Co., Ltd.) were diluted with toluene. .manufacturing) to prepare a coating liquid having a solid content of 1% by weight.

[0073] The coating liquid thus obtained was then applied on the upper surface of the first substrate layer using a mayer bar #4, and then dried by heating at a temp...

Embodiment 2

[0082] First, the same substrate as used in Example 1 was prepared.

[0083] On the other hand, 100 parts by weight of a mixture of a silicone-modified alkyd resin and an amino resin ("KS-882", manufactured by Shin-Etsu Chemical Co., Ltd.) and 1 part by weight of p-toluenesulfonate were diluted with toluene Acid (curing agent) to prepare a coating liquid with a solid content of 2% by weight.

[0084] The coating liquid thus obtained was then applied on the upper surface of the first substrate layer using a Meyer rod #4, and then dried by heating at a temperature of 140° C. for 60 seconds to form a release film having an average thickness of 0.2 μm agent layer.

[0085] Further, the coating liquid thus obtained was applied on the lower surface of the second substrate layer using a Meyer rod #4 and then dried by heating at a temperature of 140° C. for 60 seconds to form an antistatic coating having an average thickness of 0.2 μm. Floor.

[0086] Release films were prepared as...

Embodiment 3

[0088] A release film was produced in the same manner as in Example 1, except that the substrate was formed so that the surface roughness Ra of the outer surface of the first substrate layer was 5 nm, the thickness of the first substrate layer was 6 μm, and the thickness of the outer surface of the second substrate layer was The surface roughness Ra was 15 nm, and the thickness of the second base material layer was not more than 32 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com