Apparatus for conducting stack gas desulfurization with limestone grout tank arranged in lower position and method thereof

A technology for limestone slurry and desulfurization process, which is applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., to achieve the effects of reducing height, occupying a small site area, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

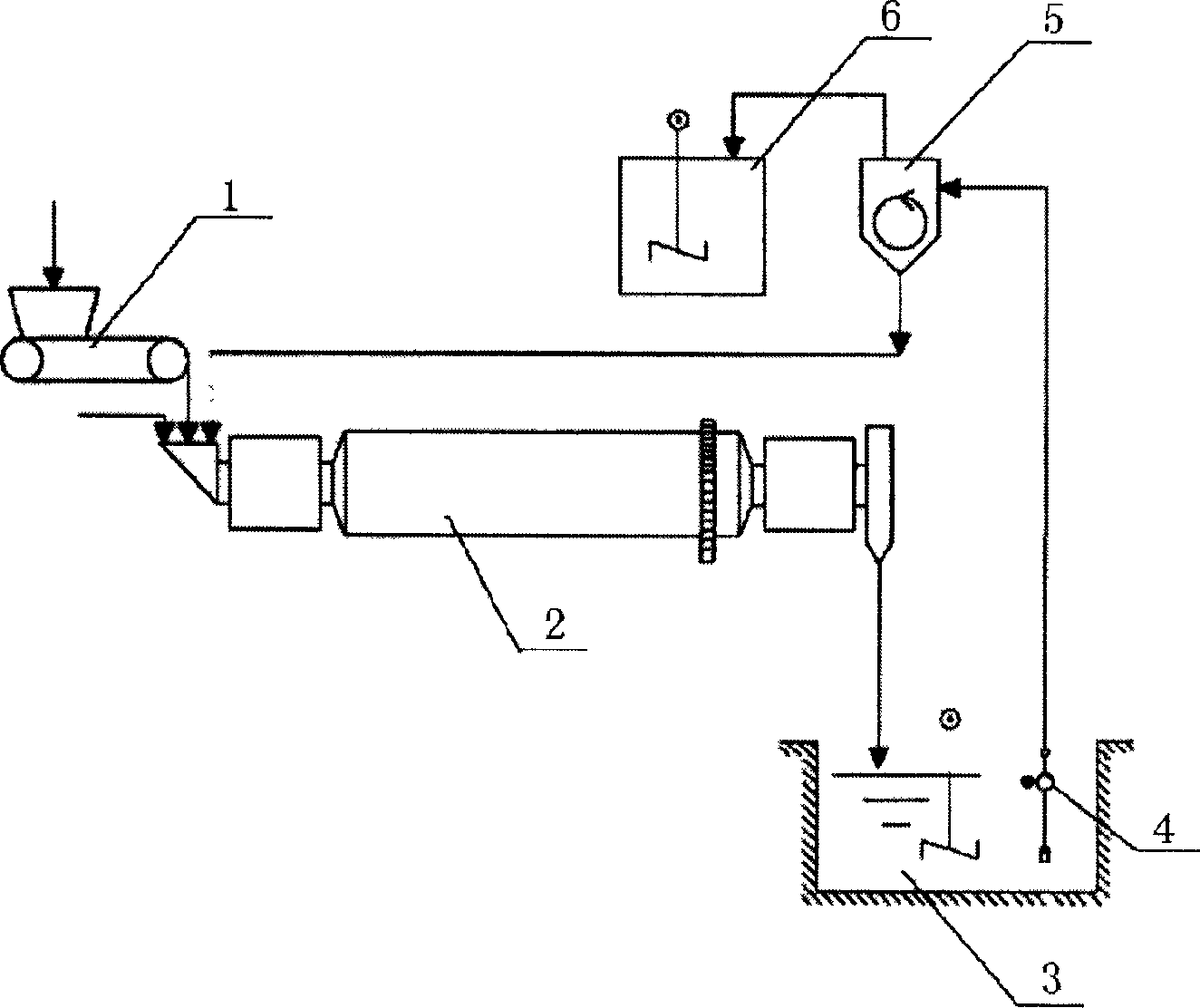

[0023] Embodiment one sees figure 1 : The wet ball mill limestone pulping system of the present invention can be divided into I-level recirculation system and II-level recirculation system to meet the needs of different particle size slurries. Limestone from mines is usually crushed into limestone blocks larger than 20 mm. The limestone particle size required by the limestone-gypsum wet flue gas desulfurization plant must meet the requirements of a fineness of less than 63 μm and a sieve rate of 90%. At the same time, the limestone powder must be prepared into a uniform slurry before it can be added to the flue gas desulfurization plant. . When the limestone particle size only needs to be finer than 63μm and the sieve rate is 90%, use figure 1 The shown I level recycling preparation process and equipment.

[0024] In the limestone slurry preparation system of the present invention, the limestone blocks are quantitatively transported into the wet ball mill 2 through the weig...

Embodiment 2

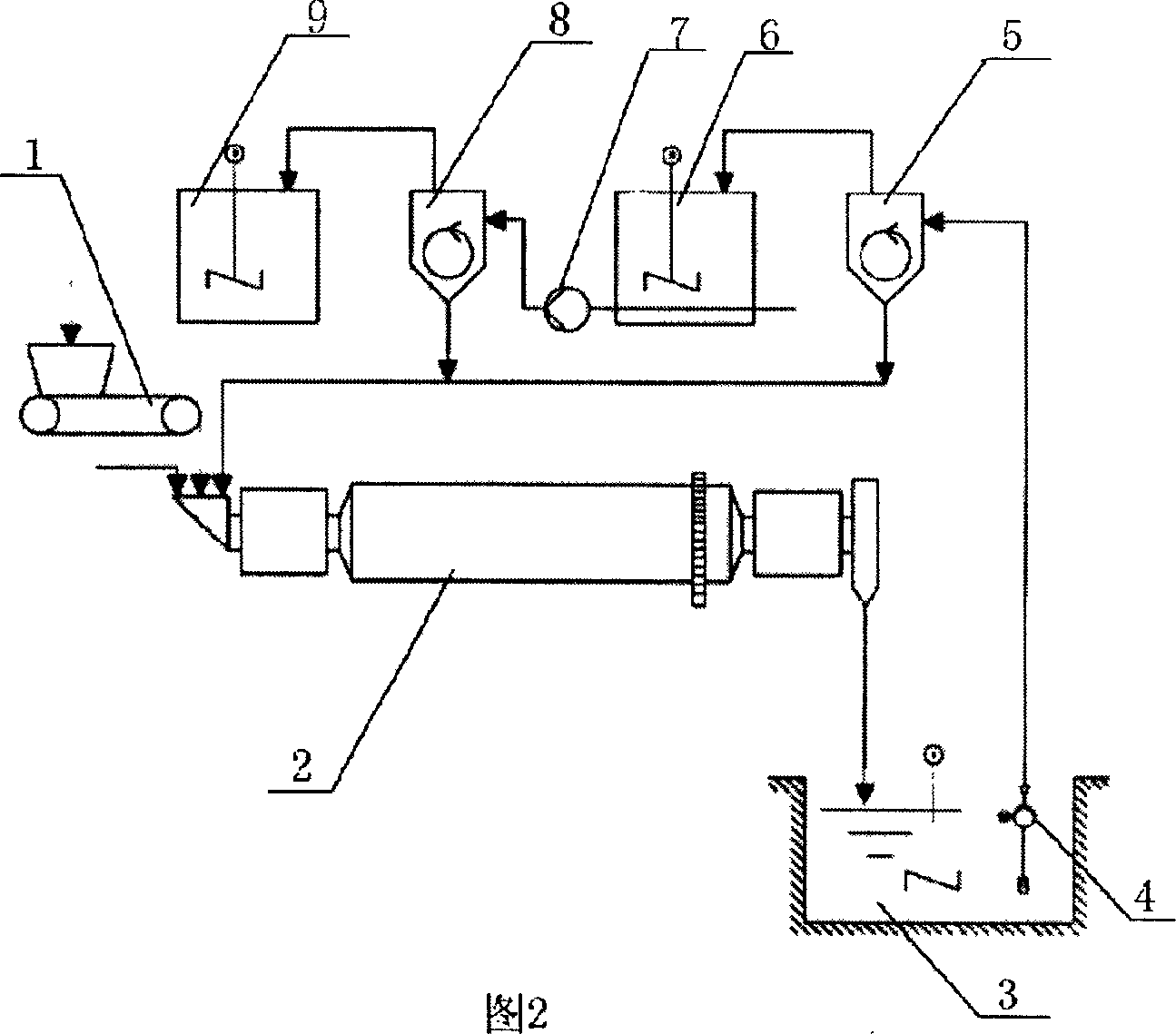

[0025] Example 2 Refer to Fig. 2: When the particle size of limestone requires a fineness of less than 31 μm and a sieving rate of 90%, the II-level recycling preparation process and device shown in Fig. 2 are generally used. The II-level recirculation system is based on the products of the I-level recirculation system, and then performs a hydrocyclone separation. After the II-level circulation separation, the slurry with a limestone particle size of less than 31 μm and a sieving rate of 90% can be obtained.

[0026] First, dig a limestone slurry tank underground to replace the previous limestone slurry tank. Second, the limestone slurry circulation pump adopts the type of submerged pump, and the pump body and impeller of the submerged pump vertically extend into the limestone slurry tank. This is because, to arrange conventional water pumps below zero meters, pump pits and corresponding accidental drainage systems need to be excavated to prevent the pumps from being submerged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com