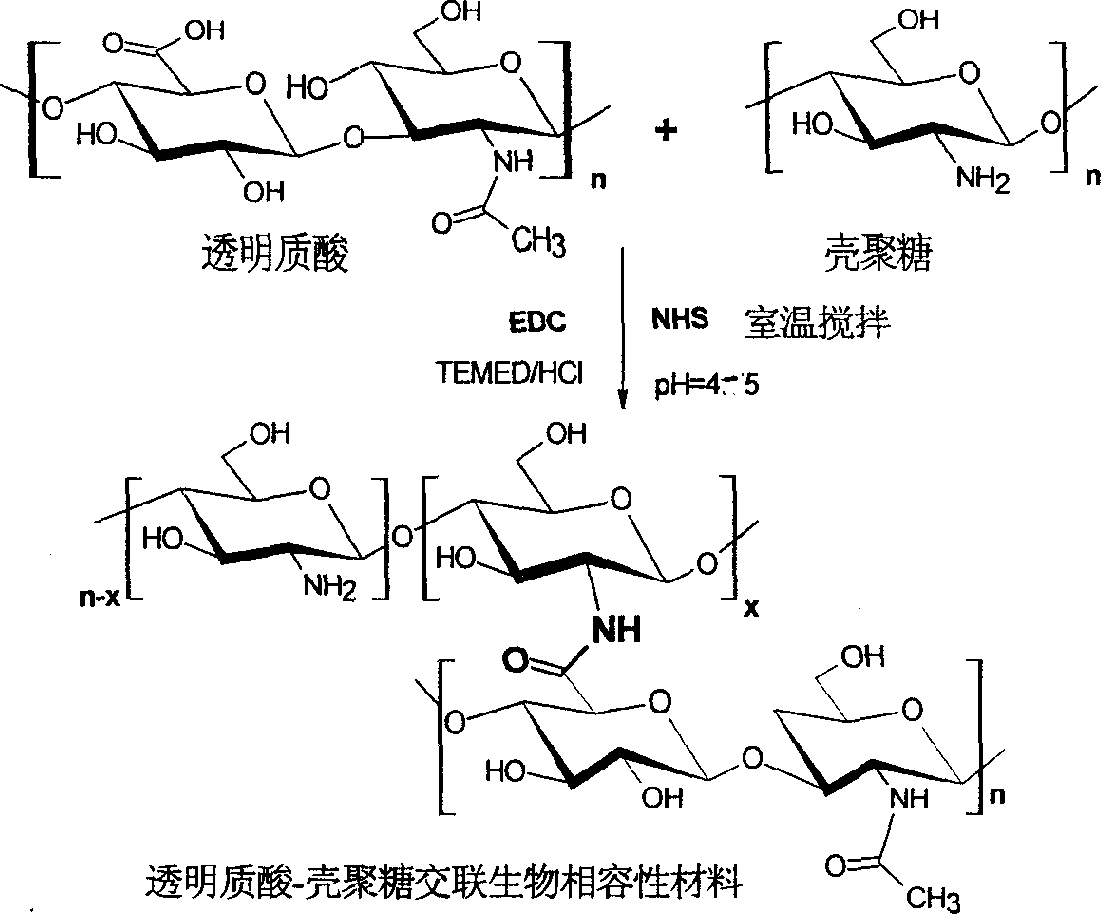

Process for preparing hyaluronic acid-chitosan crosslinked biocompatible materials

A technology of chitosan cross-linking and hyaluronic acid, applied in the field of biochemistry, can solve the problems of non-biocompatibility, single function, and no multiple biological functions, and achieve the effect of expanding application fields and high biological stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

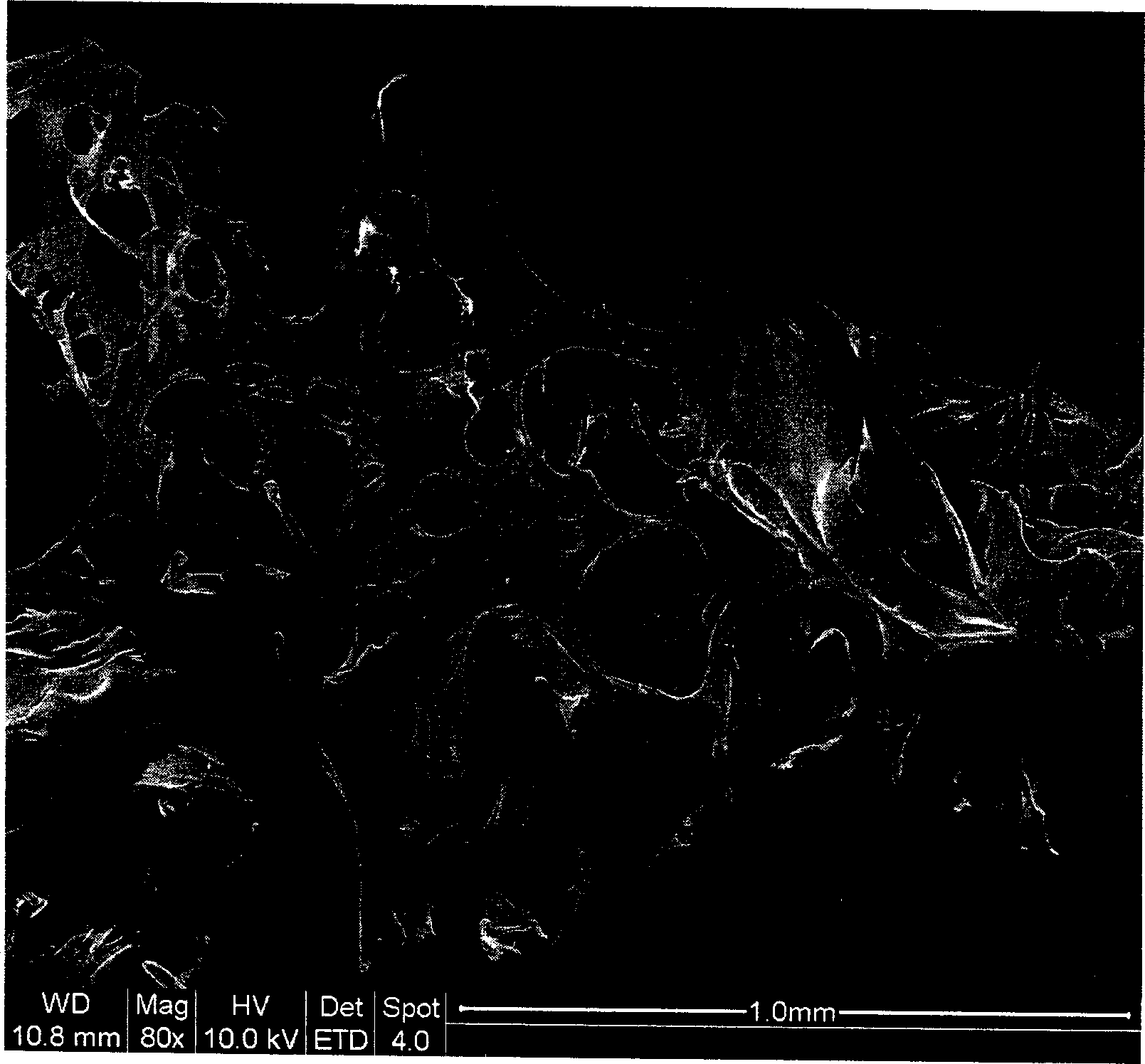

Embodiment 1

[0018] 0.2g (0.5mM) hyaluronic acid and 0.2g (1.25mM) chitosan were respectively dissolved in 20ml 0.1M HCl solution and stirred overnight. Add solid NaCl with a final concentration of 2M to the dissolved hyaluronic acid hydrochloride solution, stir well to dissolve. Weigh 0.0956g (0.5mM) EDC and 0.0575g (0.5mM) NHS, dissolve them in 5ml ultrapure water, then pour into the hyaluronic acid hydrochloric acid solution, and stir for 30min. Then inject the chitosan hydrochloric acid solution into the hyaluronic acid hydrochloric acid solution, and constantly and fully stir. When the solution is stable and uniform, slowly add liquid N,N,N',N'-tetramethylethylenediamine to the mixed solution to adjust the pH to 5.0. Stir at room temperature for 12h. The stirred product was loaded into a dialysis bag with a molecular weight cut-off of 14,000, dialyzed in 1M NaCl solution for 2 days, and then dialyzed in ultrapure water for one day. The dialysis product was freeze-dried to obtain a ...

Embodiment 2

[0020] 0.1 g of hyaluronic acid and 0.2 g of chitosan were dissolved in 20 ml of 0.1 M HCl solution and stirred overnight. Add solid NaCl with a final concentration of 2M to the dissolved hyaluronic acid hydrochloride solution, stir well to dissolve. Weigh 0.0478g EDC and 0.0288g NHS, dissolve them in 5ml ultrapure water, then pour into the hyaluronic acid hydrochloric acid solution, and stir for 30min. Then inject the chitosan hydrochloric acid solution into the hyaluronic acid hydrochloric acid solution, and constantly and fully stir. When the solution is stable and uniform, slowly add liquid N,N,N',N'-tetramethylethylenediamine to the mixed solution to adjust the pH to 4.5. Stir at room temperature for 9h. The stirred product was loaded into a dialysis bag with a molecular weight cut-off of 14,000, dialyzed in 1M NaCl solution for 2 days, and then dialyzed in ultrapure water for one day. The dialysis product was freeze-dried to obtain a mesh material.

Embodiment 3

[0022] 0.2 g of hyaluronic acid and 0.1 g of chitosan were dissolved in 20 ml of 0.1 M HCl solution, and stirred overnight. Add solid NaCl with a final concentration of 2M to the dissolved hyaluronic acid hydrochloride solution, stir well to dissolve. Weigh 0.0956g EDC and 0.0575g NHS, dissolve them in 5ml ultrapure water, then pour into the hyaluronic acid hydrochloric acid solution, and stir for 30min. Add liquid N,N,N',N'-tetramethylethylenediamine to the two polysaccharide solutions respectively to adjust the pH to 4.0. Then the chitosan hydrochloric acid solution was injected into the hyaluronic acid hydrochloric acid solution and stirred at room temperature for 6 h. The stirred product was loaded into a dialysis bag with a molecular weight cut-off of 14000, dialyzed in 1M NaCl solution for 2 days, and then dialyzed in ultrapure water for 1 day. The dialysis product was freeze-dried to obtain a mesh material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com