Dried fish floss producing process with fishbone separating machine as main apparatus

A separator and fish floss technology, which is applied in the direction of cutting fish into pieces, food science, etc., can solve the problems of simple equipment, low degree of automation, time-consuming and laborious, and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

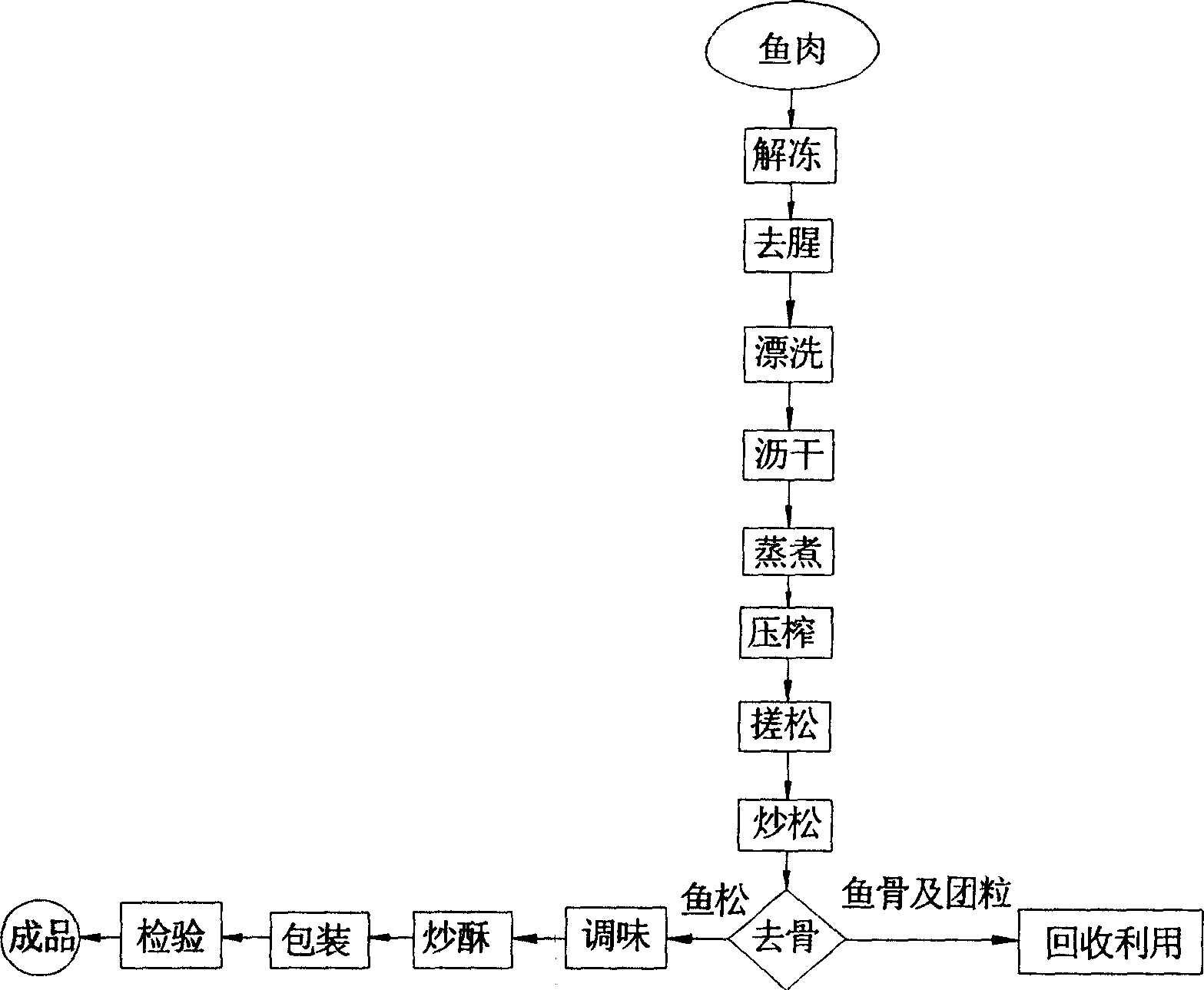

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Make spicy fish floss with tilapia minced meat

[0018] Raw material: minced tilapia fish;

[0019] Accessories: soybean powder, white vinegar, rice wine, vegetable oil, sugar, salt, monosodium glutamate, soy sauce, ginger powder, chili powder, five-spice powder.

[0020] Formula: soybean powder 5%, white vinegar 1%, rice wine 1%, vegetable oil 2%, sugar 4%, salt 4%, monosodium glutamate 0.5%, soy sauce 1%, chili powder 1%, ginger powder 0.5%, five-spice powder 0.5% ( The consumption of each auxiliary material is all the percentages of their respectively and fish meat consumption). According to the formula requirement, weighed 6 samples of fish meat with a weight of 1kg, the fish floss was produced by the technique of producing fish floss based on the fishbone separator of the present invention. 6 samples were tested, and the test results are as follows:

[0021] 1. Sensory evaluation

[0022] Color: Golden yellow, uniform; Odor: Fishy, no peculiar s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com