Elevator

A technology of lifting device and installation sleeve, which is applied in the direction of cooling bed, metal processing equipment, metal rolling, etc., can solve the problems of low guiding precision and failure to meet the lifting device, etc., and achieve the effect of high positioning precision and not easy to rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

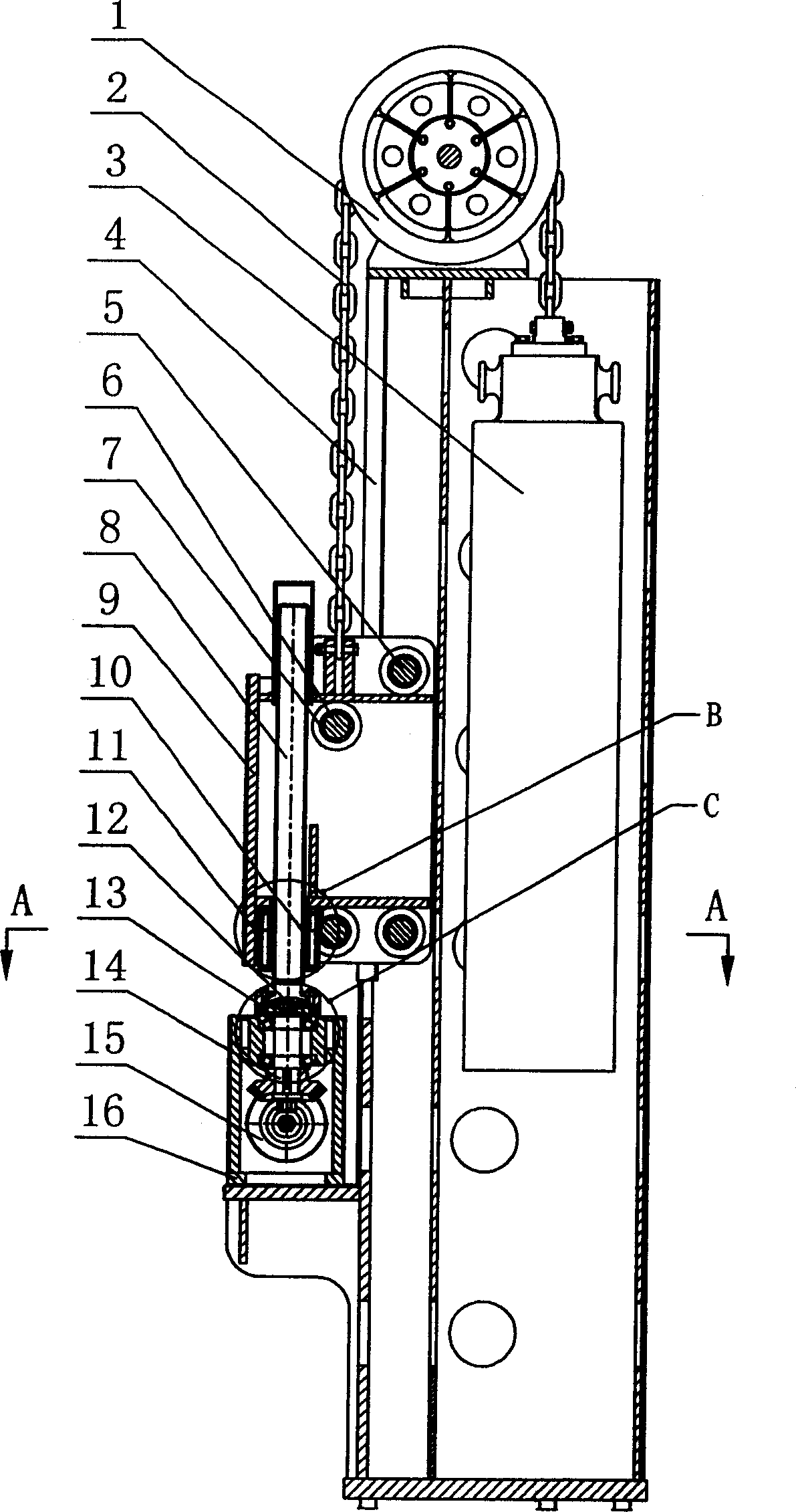

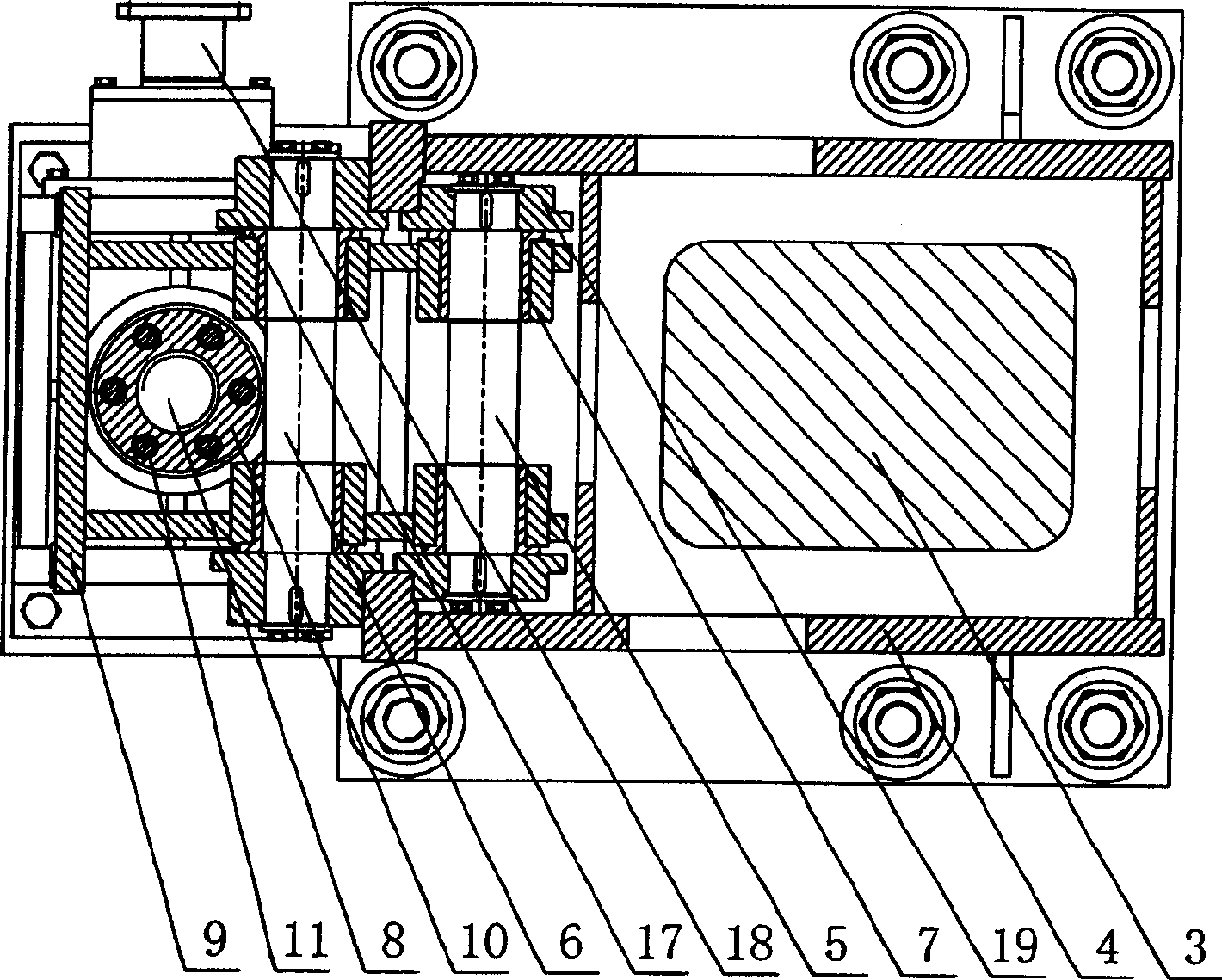

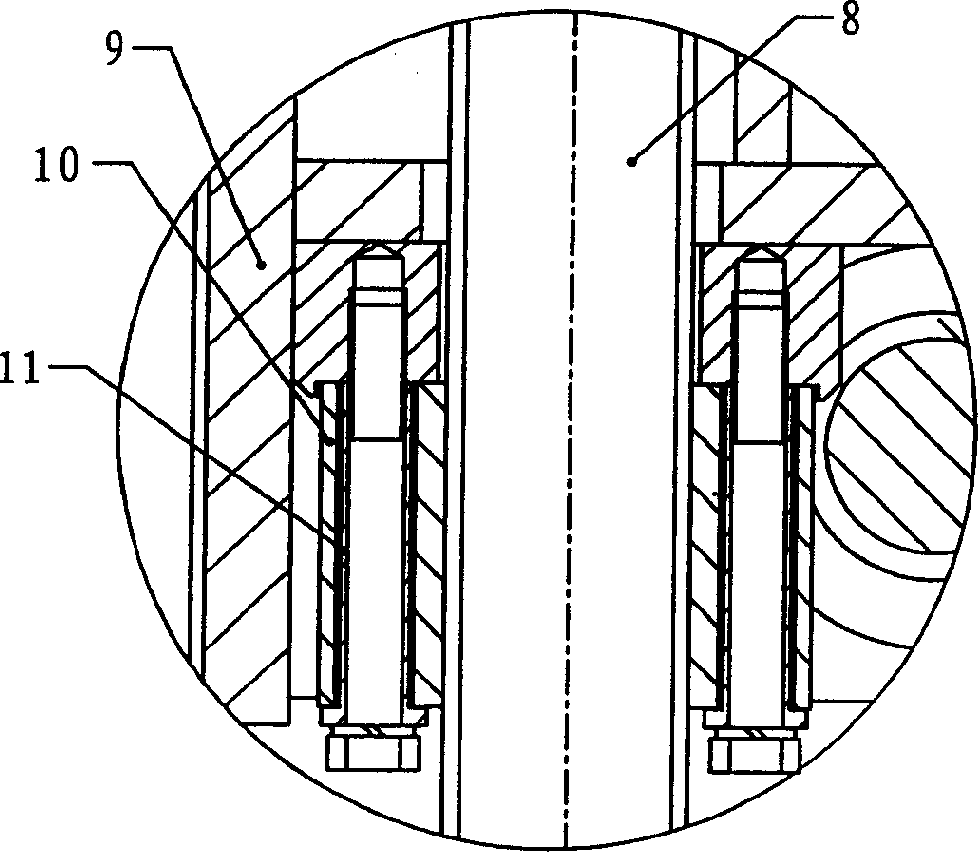

[0017] Example: such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the lifting device of the present invention includes a load-bearing sprocket 1, a ring chain 2, a counterweight 3, a column 4, an inner guide wheel shaft 5, an outer guide wheel shaft 6, a self-lubricating thrust bearing 7, a screw mandrel 8, and a lifting movement Frame 9, nut 10, nut mounting sleeve 11, spherical pad 12, spherical gland 13, vertical shaft 14, bevel gear pair 15, lifting transmission box 16, outer guide wheel 17, horizontal transmission shaft 18, inner guide wheel 19. The column 4 and the lifting mobile frame 9 are connected through a nut 10 and a screw rod 8. The two ends of the inner guide wheel shaft 5 and the outer guide wheel shaft 6 arranged on the lifting mobile frame 9 are equipped with inner and outer guide surfaces of the column 4 respectively. The inner guide wheel 19 and the outer guide wheel 17 of rolling fit, are respectively provided with self-lubricating thrust be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com