Light-emitting device, colour light filtering structure and producing method thereof

A light-emitting device and color filter technology, applied in electroluminescent light sources, lighting devices, light sources, etc., can solve the problems of degradation of the light-emitting layer, increase in complexity, and shorten the life of color filters, so as to prolong the life and improve the finished product. The effect of rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

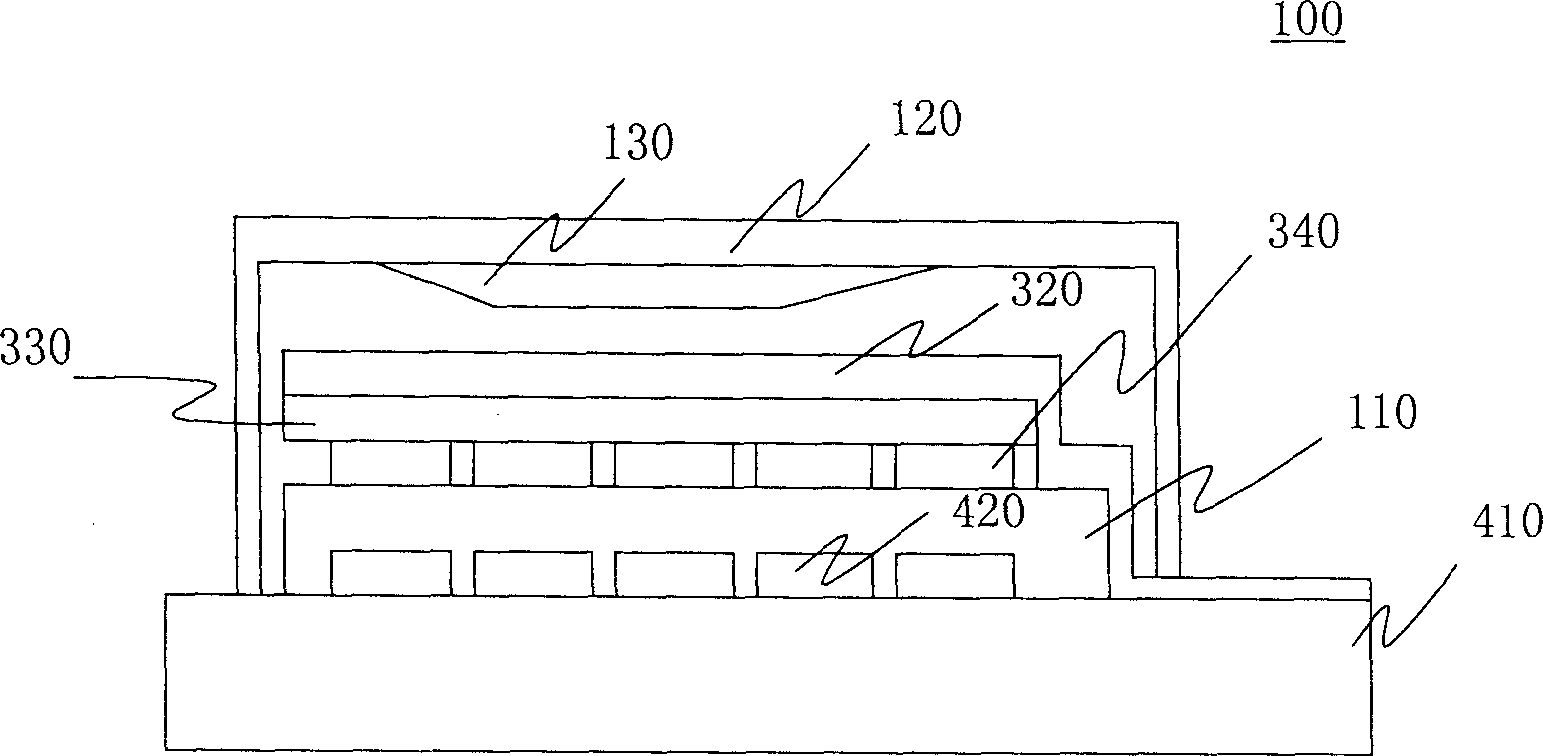

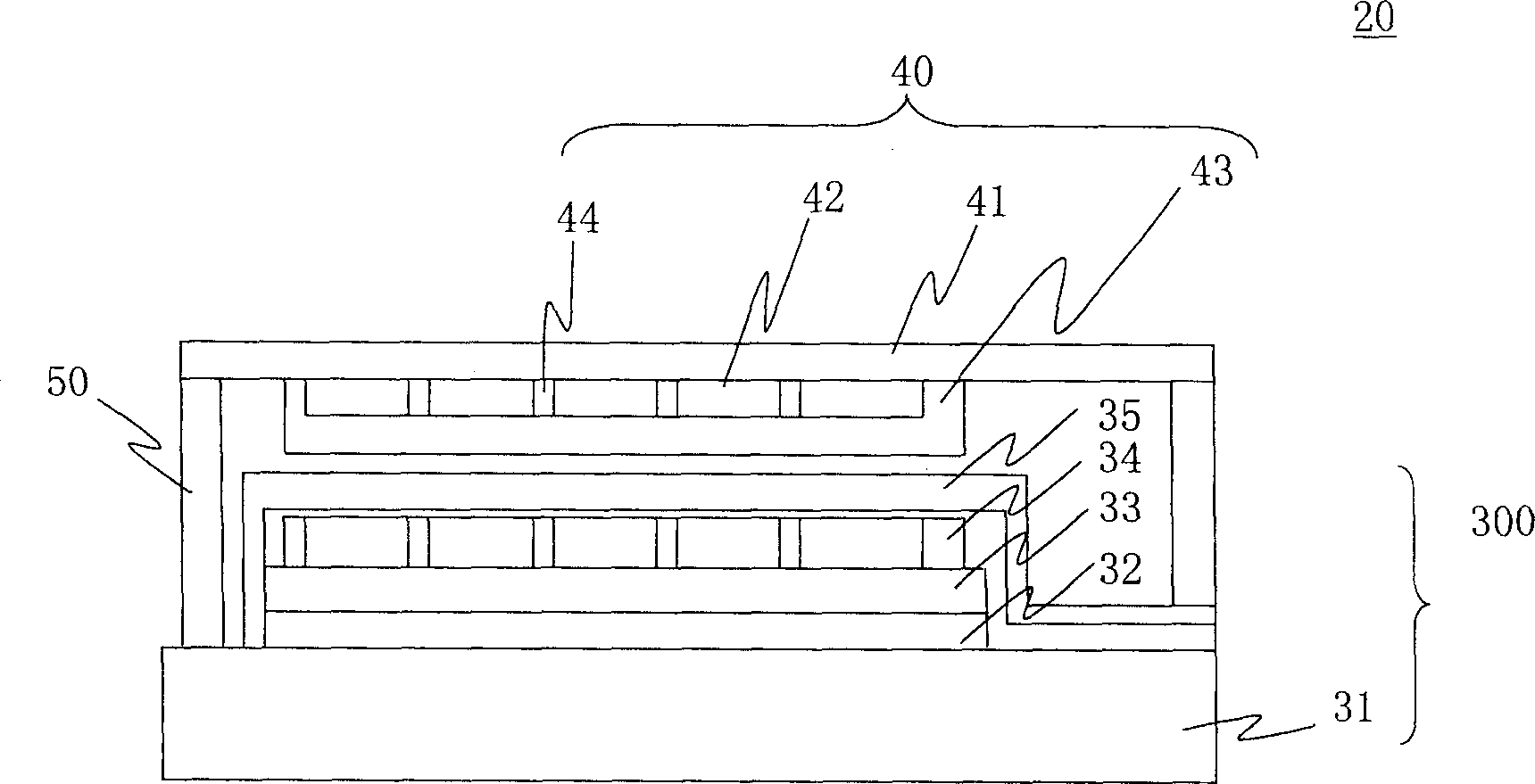

[0026] figure 2 A cross-sectional view of an embodiment of a light-emitting device of the present invention is shown. The light emitting device 20 includes: a light emitting portion 30 and a color filter structure 40 . The color filter structure 40 includes: a first substrate 41 , a filter component 42 and a first protection layer 43 . The light emitting part 30 includes: a second substrate 31 , a first electrode 32 , a light emitting layer 33 , a second electrode 34 and a second protection layer 35 . When the light emitting layer 33 is an organic light emitting layer, the light emitting device 20 is an organic electroluminescent device.

[0027] A multi-array control element (not shown in the known figure) is formed on the second substrate 31 , and each control element is composed of a switching thin film crystal, a driving thin film crystal and a capacitor. The reflectance of the second substrate 31 can be lower than that of the first electrode 32 and the second electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com