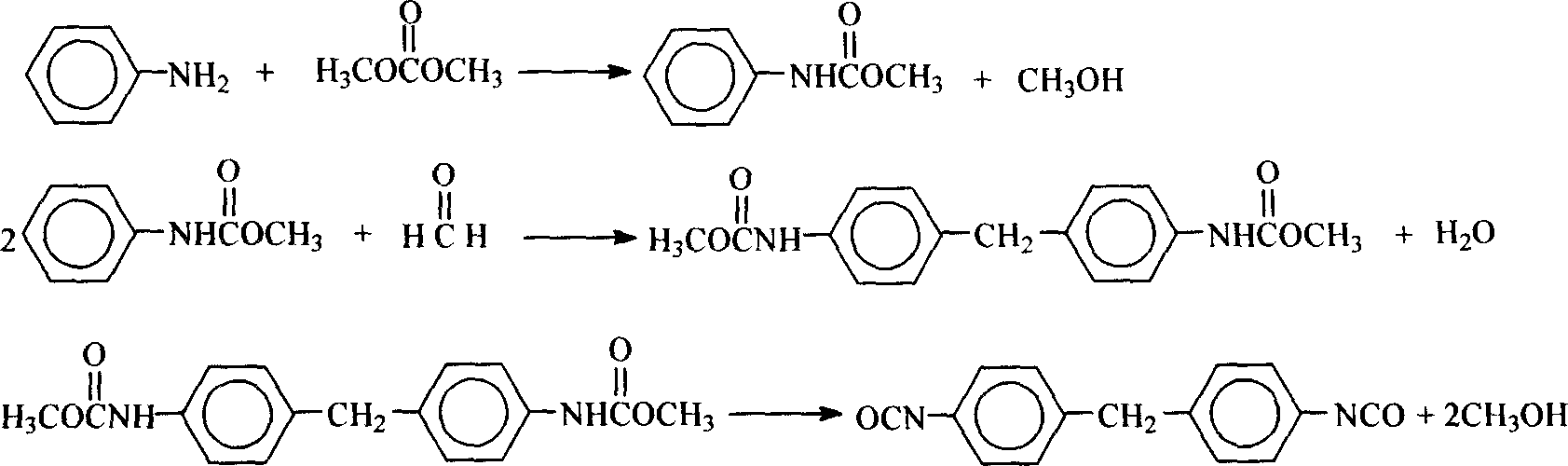

Catalyst for synthesizing phenyl-methyl-formater, its preparing and applicating method

A technology of methyl phenylcarbamate and an application method, applied in the field of TiO2-ZnO catalysts, can solve the problems of unrecyclable homogeneous catalysts, difficult product separation, unfriendly environment, etc., and achieves high repeatability, easy separation and recovery, and stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 0.015mol of tetrabutyl titanate, dissolve it in 100ml of anhydrous methanol, and make a solution with a concentration of 0.15mol / L;

[0028] (2) Add deionized water dropwise to the tetrabutyl titanate methanol solution prepared in step (1), until the tetrabutyl titanate is completely hydrolyzed;

[0029] (3) Vacuum suction filtration of the hydrolyzate of tetrabutyl titanate obtained in step (2), and washing with the same amount of deionized water as in step (2);

[0030] (4) According to the molar weight and molar ratio of tetrabutyl titanate taken in (1) step ZnO: TiO 2 =1:1 calculation, weigh 0.015mol Zn(OOCCH 3 ) 2 2H 2 O, dissolved in 10ml of water to make a solution with a concentration of 1.5mol / L, mix the solution with the hydrolyzate of tetrabutyl titanate prepared in step (3), and dry at 80°C for 8 hours to obtain a catalyst precursor ;

[0031] (5) the catalyst precursor that (4) step makes is roasted 8 hours at 500 ℃, makes the TiO that synthe...

Embodiment 2-4

[0033] Identical to the preparation method of Example 1, just changing the roasting temperature of the catalyst precursor in the step (5) is respectively 400°C, 600°C, and 700°C to obtain the respective TiO used for the synthesis of methyl phenylcarbamate of the present invention. 2 - ZnO catalyst.

Embodiment 5-7

[0035] Same as the preparation method of Example 1, just change Zn(OOCCH 3 ) 2 2H 2 The amount of O used is 0.03mol, 0.0075mol, 0.0038mol, respectively, dissolved in 10ml of water to prepare solutions with concentrations of 3mol / L, 0.75mol / L, and 0.38mol / L, so that the molar ratio ZnO:TiO 2 Respectively 1: 0.5, 1: 2, 1: 4, make respective TiO used for synthesizing methyl phenylcarbamate of the present invention 2 - ZnO catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com