Technology and apparatus for preparing cyclohexanol, cyclohexanone and adipic acid by cyclohexane

A technology for air oxidation and cyclohexane, which is applied in the field of cyclohexanol prepared by air oxidation of cyclohexanone, adipic acid and cyclohexane, which can solve the problem of unsatisfactory metalloporphyrin catalytic effect, cyclohexane conversion rate and reaction selectivity And low yield of oxidation products, lower reaction temperature and pressure, etc., to achieve the effect of reducing the formation of deep oxidation products, inhibiting a series of side reactions, and improving the reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

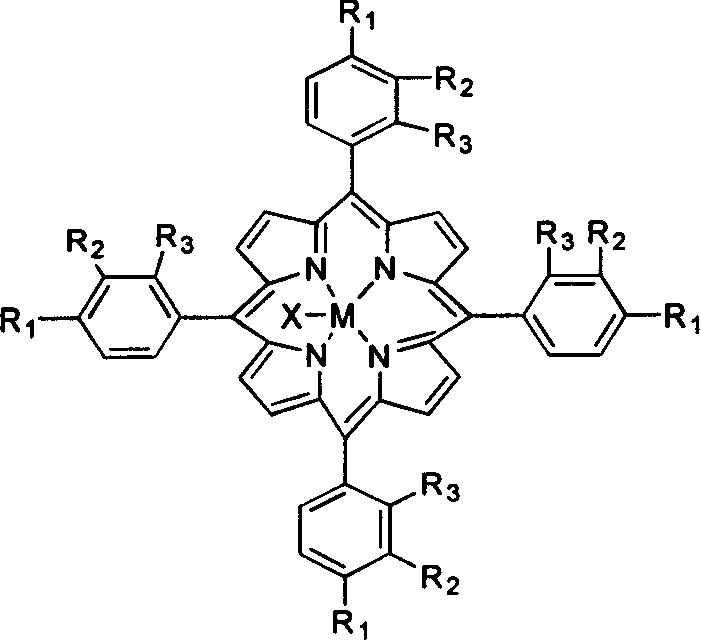

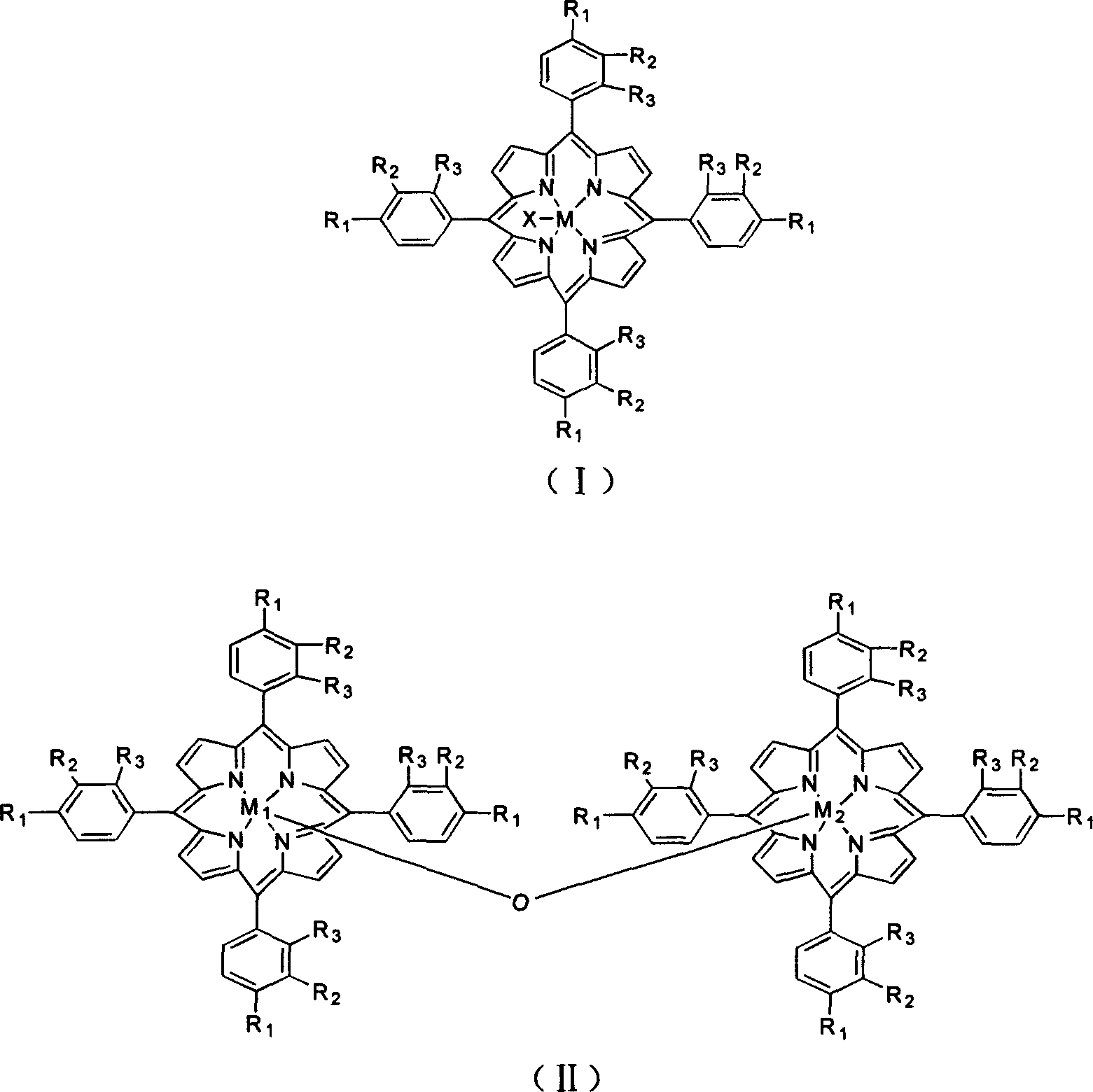

Embodiment 1

[0011] The reaction equipment includes two bubble column reactors with external circulation and a tubular reactor connected in series. Production process: at 150°C, the metalloporphyrin dissolved in 10PPM structural formula (I) is introduced, R 1 = H, R 2 = R 3 =CH 3 , M=Mn cyclohexane, 0.4MPa air through the gas distributor is passed into the bottom of the first bubble column reactor, and the reaction liquid overflows from the upper part of the first bubble column reactor into the second bubble column At the bottom of the tower reactor, the catalyst-containing cyclohexane and the reaction liquid overflowing from the upper part of the second bubble column reactor are mixed with air by the Venturi mixer and then enter the tubular reactor, and the flow rate of the cyclohexane is controlled to make the residence The time is 90 minutes. The oxidized liquid from the tubular reactor is cooled and separated to obtain adipic acid crystals, the filtrate is decomposed after flash ev...

Embodiment 2

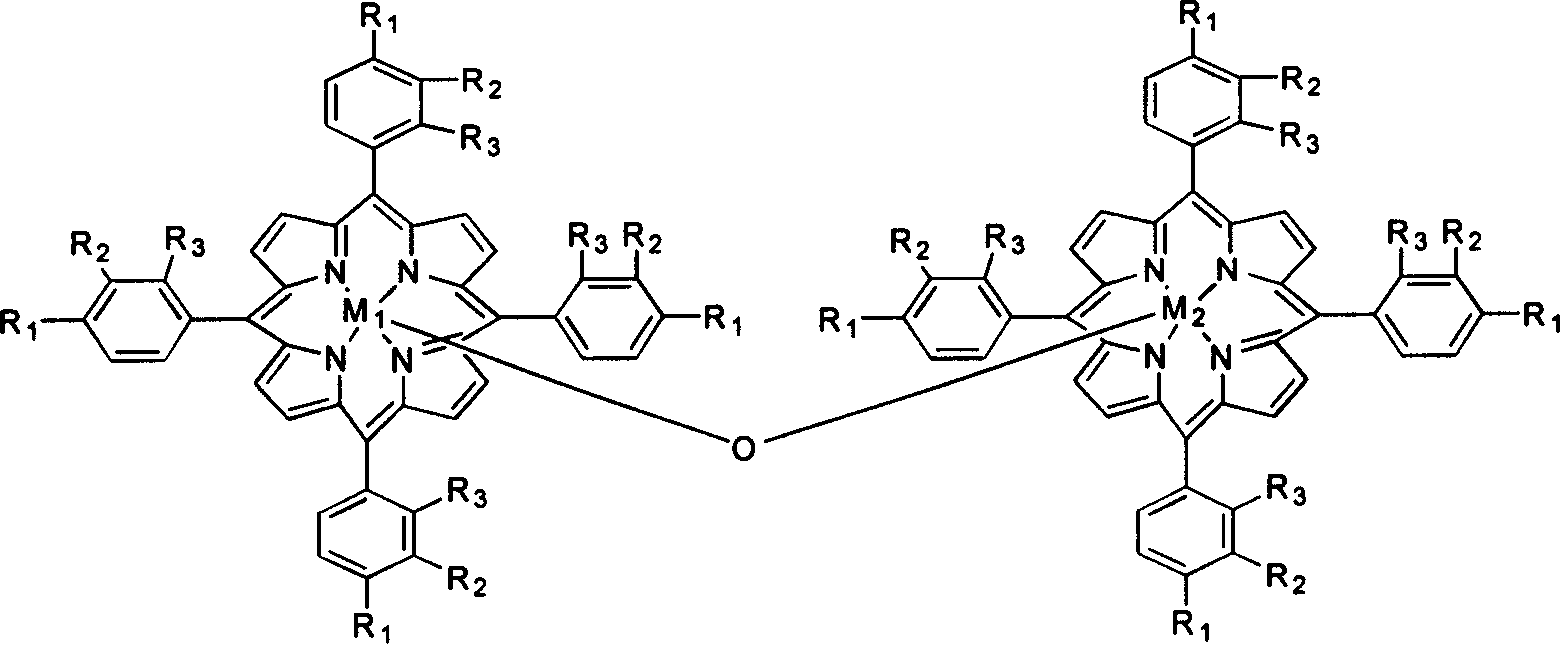

[0013] The reaction equipment includes 6 tank reactors with agitator connected in series. Production process: the catalyst is a metalloporphyrin with structural formula (II), R 1 = R 2 =OCH 3 , R 3 =Cl,M 1 = M 2 =Fe, the oxidant is 0.8MPa air. The cyclohexane containing 2PPM catalyst and the air through the gas distributor are passed into the bottom of the first reactor, and the reaction liquid overflows from the upper part of the first reactor to the bottom of the second reactor, and the reaction temperature is 145 ° C. The reaction pressure is 0.9MPa, and the reaction liquid overflowing from the upper part of the second reactor enters the third reactor, and then passes through the fourth, fifth and sixth reactors in sequence. Control the cyclohexane flow rate to make the residence time 45 minutes, and control the air flow rate to make the tail oxygen content not exceed 5%. The oxidized liquid is decomposed after being flashed, and the cyclohexane is recovered through ...

Embodiment 3

[0015] The reaction equipment includes two tank reactors with agitator and a tubular reactor connected in series. Production process flow: the catalyst is a metalloporphyrin with structural formula (I), R 1 = R 2 =C 2 h 5 , R 3 =Br, M=Fe, the oxidant is 0.6MPa air containing 25% oxygen. The cyclohexane containing 20PPM catalyst is passed into the bottom of the first tank reactor through the air of the gas distributor, and the reaction liquid overflows from the upper part of the first tank reactor into the bottom of the second tank reactor, and the reaction The temperature was 160°C. The reaction solution overflowed from the upper part of the second tank reactor was mixed with air by a Venturi mixer and then entered the tubular reactor, and the flow rate of toluene was controlled so that the residence time was 90 minutes. The oxidized liquid coming out of the tubular reactor is cooled and separated to obtain benzoic acid crystals, the filtrate is decomposed after being fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com