Method for preparing adipate

A technology for adipic acid and cyclohexane, which is applied in the field of one-step preparation of adipic acid by catalytic oxidation of cyclohexane, can solve the problem of high cost, and achieve the effects of low cost, low reaction temperature and pressure, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Nitrogen-doped activated carbon preparation method, the specific steps are as follows:

[0040] (1) Activated carbon is first soaked in 2mol / L hydrochloric acid at 80°C for 2 hours, then soaked in 1mol / L hydrofluoric acid at room temperature for 24 hours, then washed with distilled water until neutral, dried and heat-treated at 1000°C in Ar atmosphere for 2 hours, After natural cooling, screen out activated carbon with a diameter of 40-60 mesh;

[0041] (2) The activated carbon treated in step (1) was heated to 500 °C in an Ar atmosphere, and then NH 3 , NH 3 Flow accounted for NH 3 and 20% of the total flow of Ar, was treated at a constant temperature for 1 h, and cooled to room temperature in an Ar atmosphere to obtain nitrogen-doped activated carbon. The doping amount of nitrogen is about 2% (mass fraction).

[0042] Preparation method of nitrogen-doped carbon nanotubes:

[0043] (1) Preparation of Fe-Mo / Al by co-precipitation method 2 o 3 Catalyst: Ferric nit...

Embodiment 1

[0048] 94g of cyclohexane, 2.7g of cyclohexanone, 62.6g of acetone, and 0.2g of nitrogen-doped activated carbon were added into a closed reaction kettle and mixed to form a mixed suspension. The mixed suspension was heated to 125°C under stirring, and oxygen was fed to 1.5Mpa, and the temperature and pressure were kept constant. After 8 hours of reaction, it was cooled to room temperature, and the liquid-solid phase mixture was taken out, and it was filtered to obtain a solid catalyst (nitrogen doped activated carbon) and a liquid phase mixture containing unreacted reactants and reaction products.

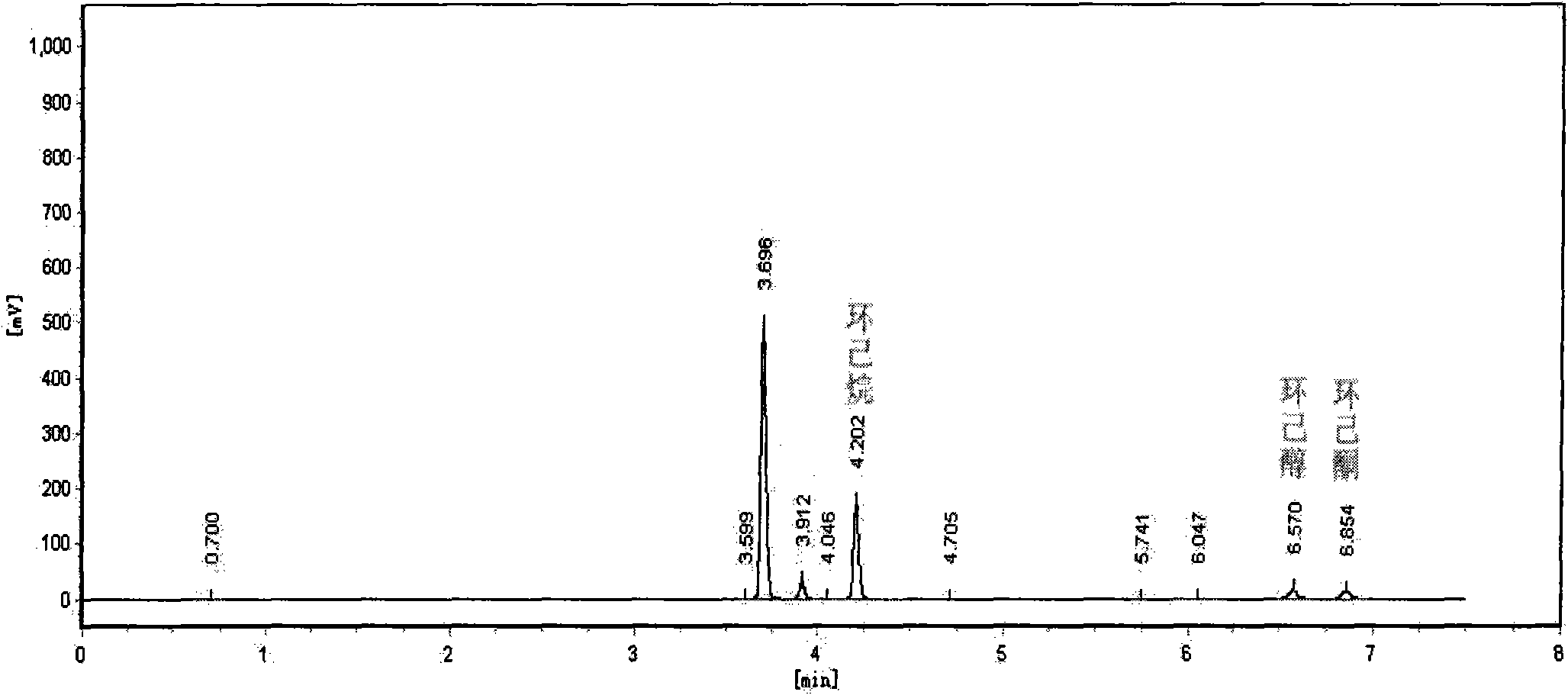

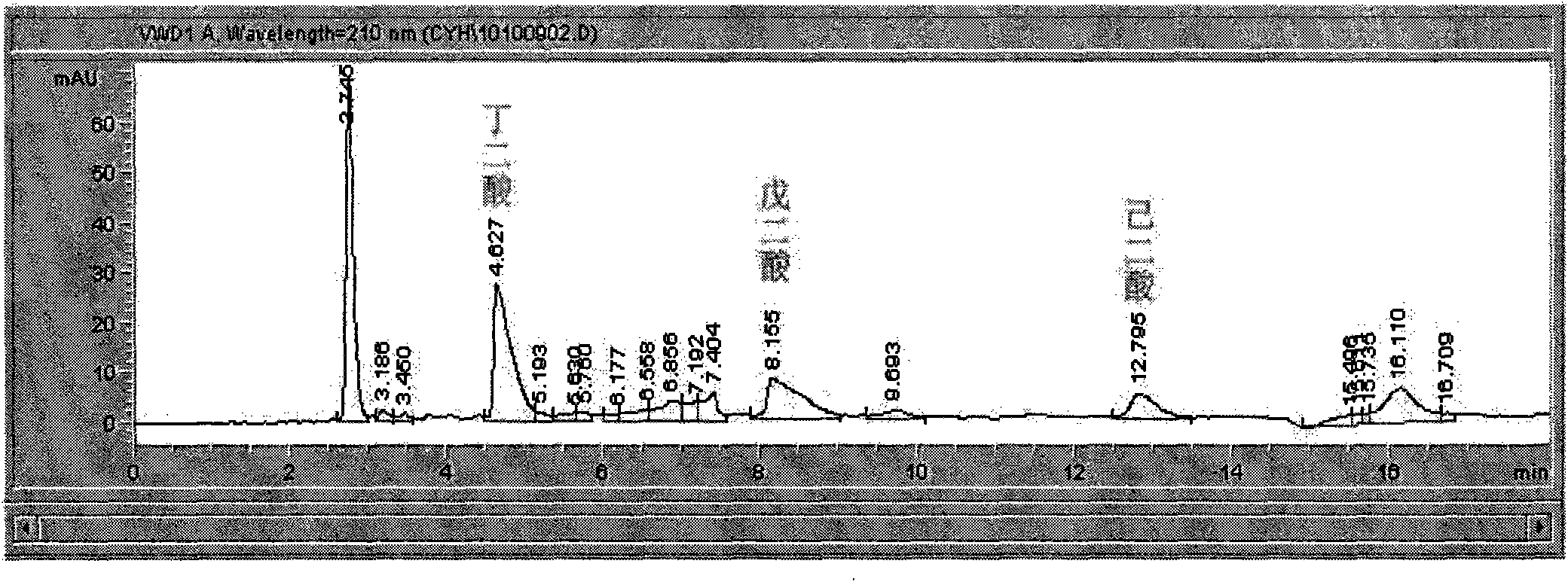

[0049] The above liquid phase mixture was analyzed to determine the conversion and selectivity of the reaction. The analysis method is carried out according to the method disclosed in the patent CN1936586A, wherein the analysis of cyclohexane, cyclohexanone and cyclohexanol is carried out on the Agilent 6820 gas chromatograph equipped with a capillary column, and the analysis of ad...

Embodiment 2

[0051] 94g of cyclohexane, 9.4g of cyclohexanone, 62.6g of acetone, and 9.4g of nitrogen-doped activated carbon were added into a closed reaction kettle and mixed to form a mixed suspension. The mixed suspension was heated to 200°C under stirring, and oxygen was fed to 5Mpa, and the temperature and pressure were kept constant. After 8 hours of reaction, it was cooled to room temperature, the liquid-solid phase mixture was taken out, and it was filtered to obtain a solid catalyst (nitrogen doped heterogeneous activated carbon) and a liquid phase mixture containing unreacted reactants and reaction products.

[0052] The above liquid phase mixture was analyzed to determine the conversion and selectivity of the reaction. The analysis method is carried out according to the method disclosed in the patent CN1936586A, wherein the analysis of cyclohexane, cyclohexanone and cyclohexanol is carried out on the Agilent 6820 gas chromatograph equipped with a capillary column, and the analys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com