Gear shift actuator for mechanical automatic speed transmission

A technology for automatic transmissions and actuators, applied to mechanical equipment, transmission control, and components with teeth, etc., can solve problems such as poor maintainability and assembly, high labor intensity, frequent manipulation, etc., to achieve convenient maintenance and reduce labor Strength, easy operation and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

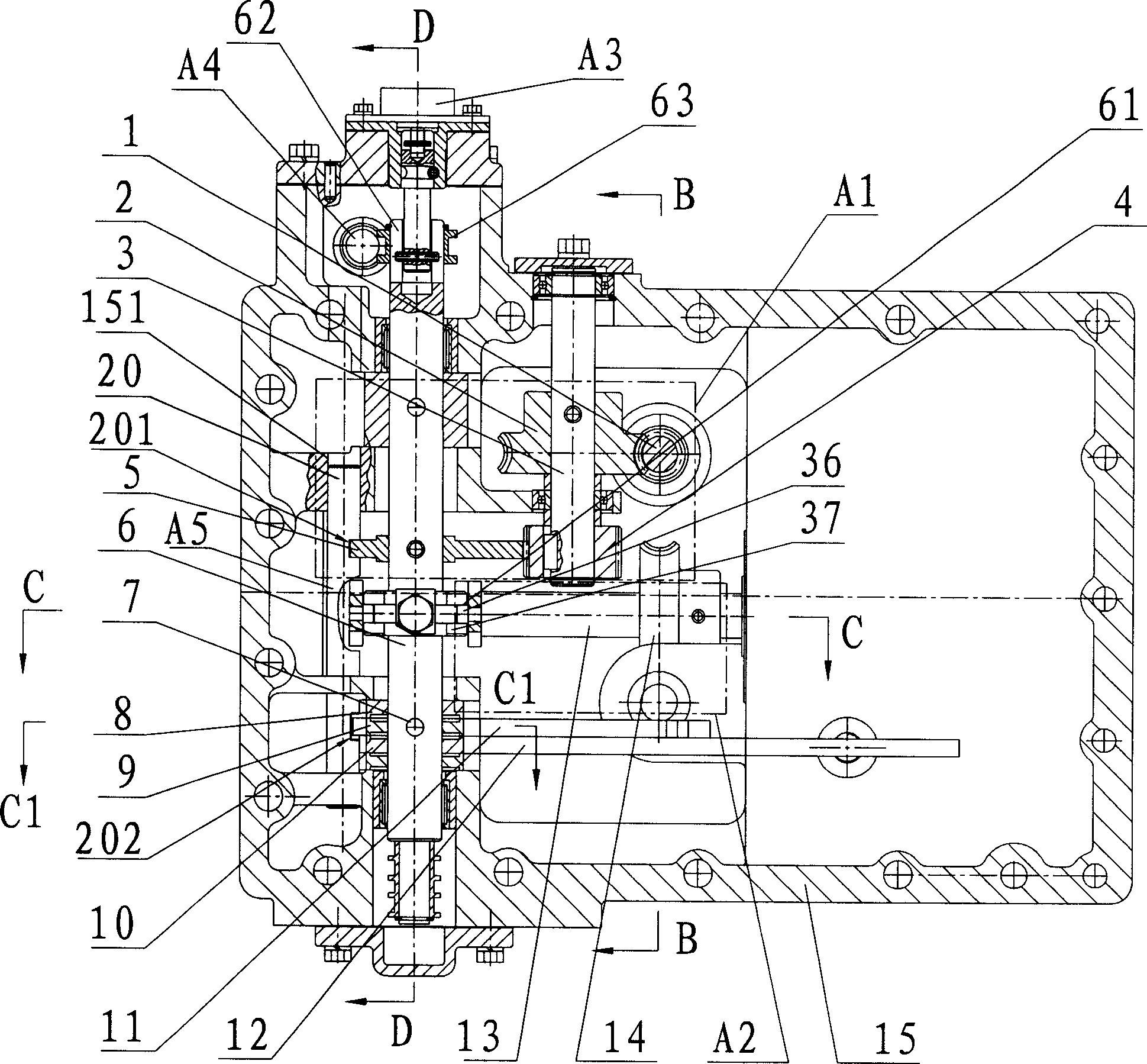

[0019] Taking the transmission of six gears as an example below, the present invention will be further described. Wherein the intermediate gear shifting block and the intermediate gear connecting rod have only one piece each, which are respectively two / three speed shifting blocks 9 and two / three speed connecting rods 11.

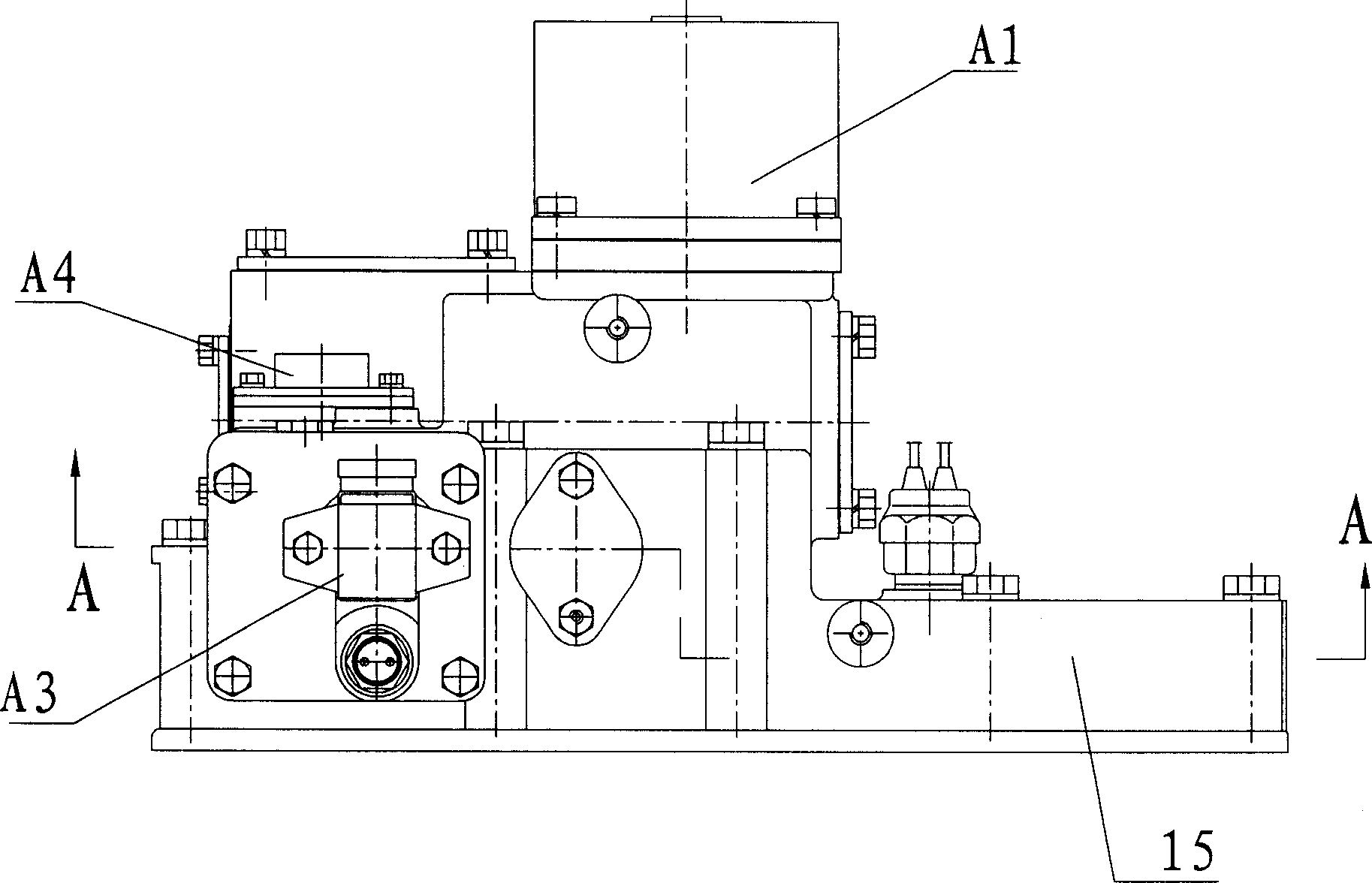

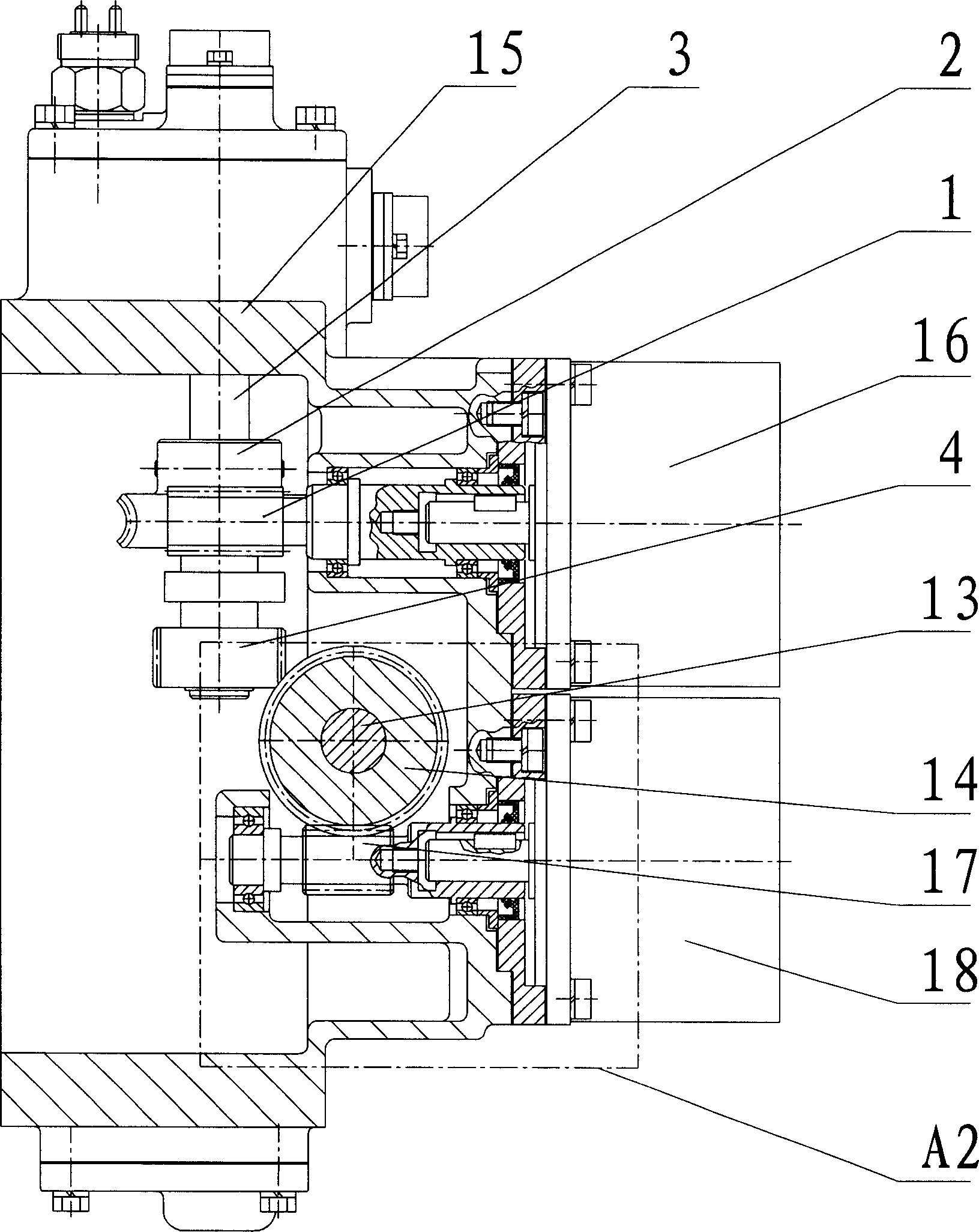

[0020] Such as figure 1 , 2 , 9, the mechanical automatic transmission shift actuator of the present invention includes a casing 15 and a joystick 6 installed in the casing 15, and the joystick 6 is connected with a motor-driven motor that can make the joystick 6 swing. The joystick swing transmission mechanism A1, the joystick movement transmission mechanism A2 driven by the motor that can make the joystick 6 move, the joystick swing position detection mechanism A3, the joystick movement position detection mechanism A4 and the gear interlock mechanism A5, in the operation The driven gear 5 is fixed on the rod 6 by an elastic cylindrical pin, and the joyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com