Method for producing tissue vegetable protein

A plant protein and material technology, applied in the direction of plant peptides, peptide sources, etc., can solve the problems of increasing process complexity and production cost, reducing flavor consumer acceptance, non-conformity, etc., to solve system instability, strong elasticity and toughness. , The effect of solving the feeding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

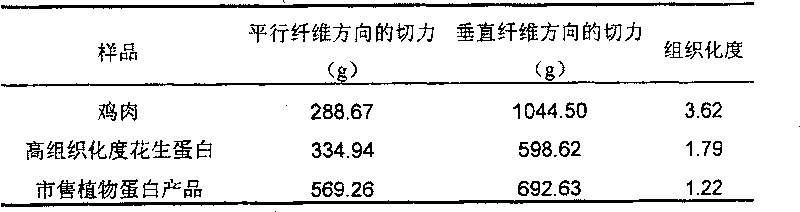

[0019] Embodiment 1, the production of highly textured peanut protein

[0020] 1. Production of highly organized peanut protein

[0021] 1) 1 kg of edible peanut meal is pulverized into coarse powder with a hammer mill;

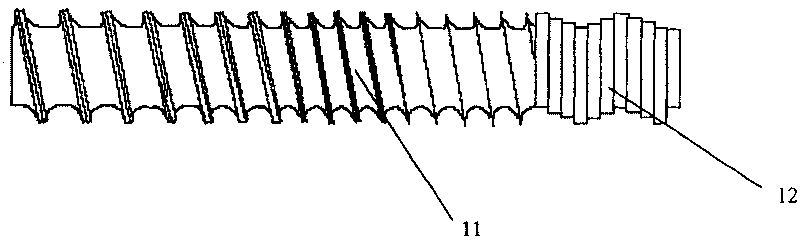

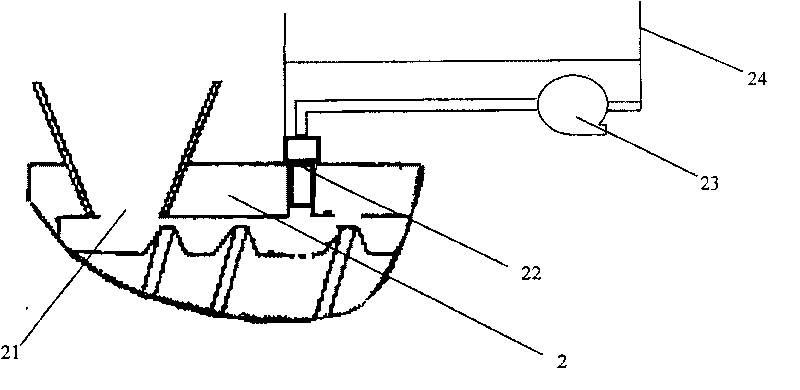

[0022] 2) Preheat the DSE-25 twin-screw extruder produced by Brabender Food Instruments in Germany. The temperature of each zone of the extruder barrel is preset as follows: Zone 1, 70°C; Zone 2, 120°C; Zone 3 zone, 160°C; zone four, 110°C; 2×20mm square die, 70°C;

[0023] 3) After the temperature of the cylinder in each zone of the extruder reaches the preset value, pre-modulate the peanut meal until the moisture content reaches 15%, and then feed the peanut meal, and the feeding speed is set at 25g / min;

[0024] 4) Add water to the material through a twin-screw extruder, and adjust the amount of water added until the final moisture content of the material reaches 50%;

[0025] 5) Carry out extrusion texture processing, the temperature of the die head is...

Embodiment 2

[0048] Embodiment 2, the production of highly textured soybean protein

[0049] 1) 1 kg of edible low-temperature soybean meal is pulverized into coarse powder with a hammer mill;

[0050] 2) Preheat the twin-screw extruder. The temperature of each zone of the extruder barrel is preset as follows: zone 1, 80°C; zone 2, 110°C; zone 3, 150°C; zone 4, 120°C; 1×40mm type Die head, 75°C;

[0051] 3) After the temperature of the cylinder in each zone of the extruder reaches the preset value, add water to the pulverized low-temperature soybean meal until the moisture content reaches 20%, and then feed the material, and the feeding speed is set at 35g / min;

[0052] 4) Add water to the material through a twin-screw extruder, and adjust the amount of water added until the final moisture content of the material reaches 55%;

[0053] 5) Carry out extrusion texture processing, the temperature of the die head is controlled at 75°C, and the screw speed is set at 120rpm to obtain regular, s...

Embodiment 3

[0055] Embodiment 3, the production of highly textured soybean protein

[0056] 1) 1 kg of edible low-temperature soybean meal is pulverized into coarse powder with a hammer mill;

[0057] 2) Preheat the twin-screw extruder. The temperature of each zone of the extruder barrel is preset as follows: zone 1, 90°C; zone 2, 120°C; zone 3, 155°C; zone 4, 120°C; Round die head, 80°C;

[0058] 3) After the temperature of the cylinder in each zone of the extruder reaches the preset value, add water to the pulverized low-temperature soybean meal until the moisture content reaches 15%, and then feed, and the feed speed is set at 35g / min;

[0059] 4) Add water to the material through a twin-screw extruder, and adjust the amount of water added until the final moisture content of the material reaches 55%;

[0060] 5) Carry out extrusion texture processing, the temperature of the die head is controlled at 70°C, and the screw speed is set at 120rpm to obtain a product that is full of elasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

| chewiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com