Plasma processing apparatus and method

A plasma and processing device technology, applied in the field of plasma processing devices, can solve the problems of high manufacturing cost, hindering uniform electromagnetic field, uneven plasma, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

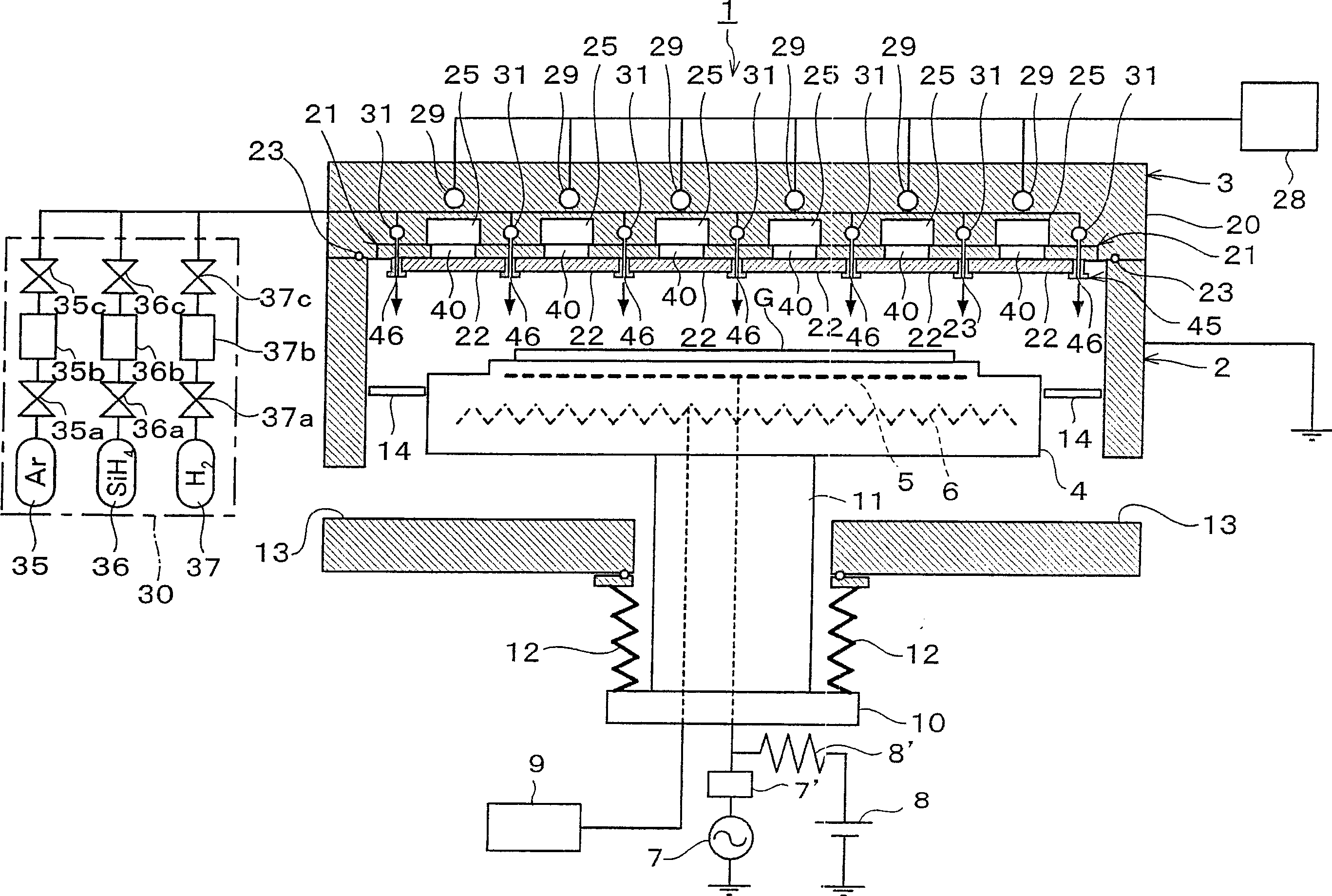

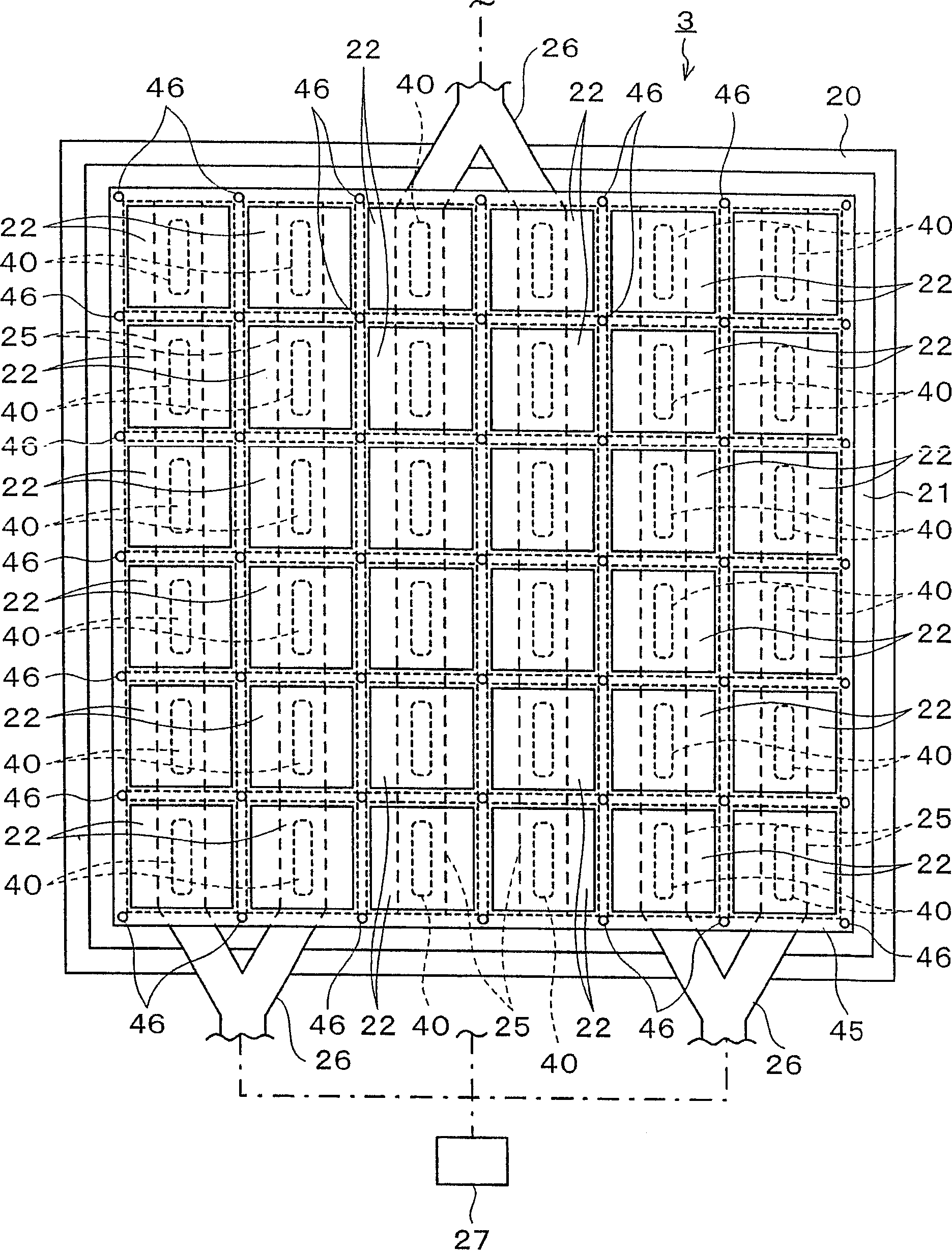

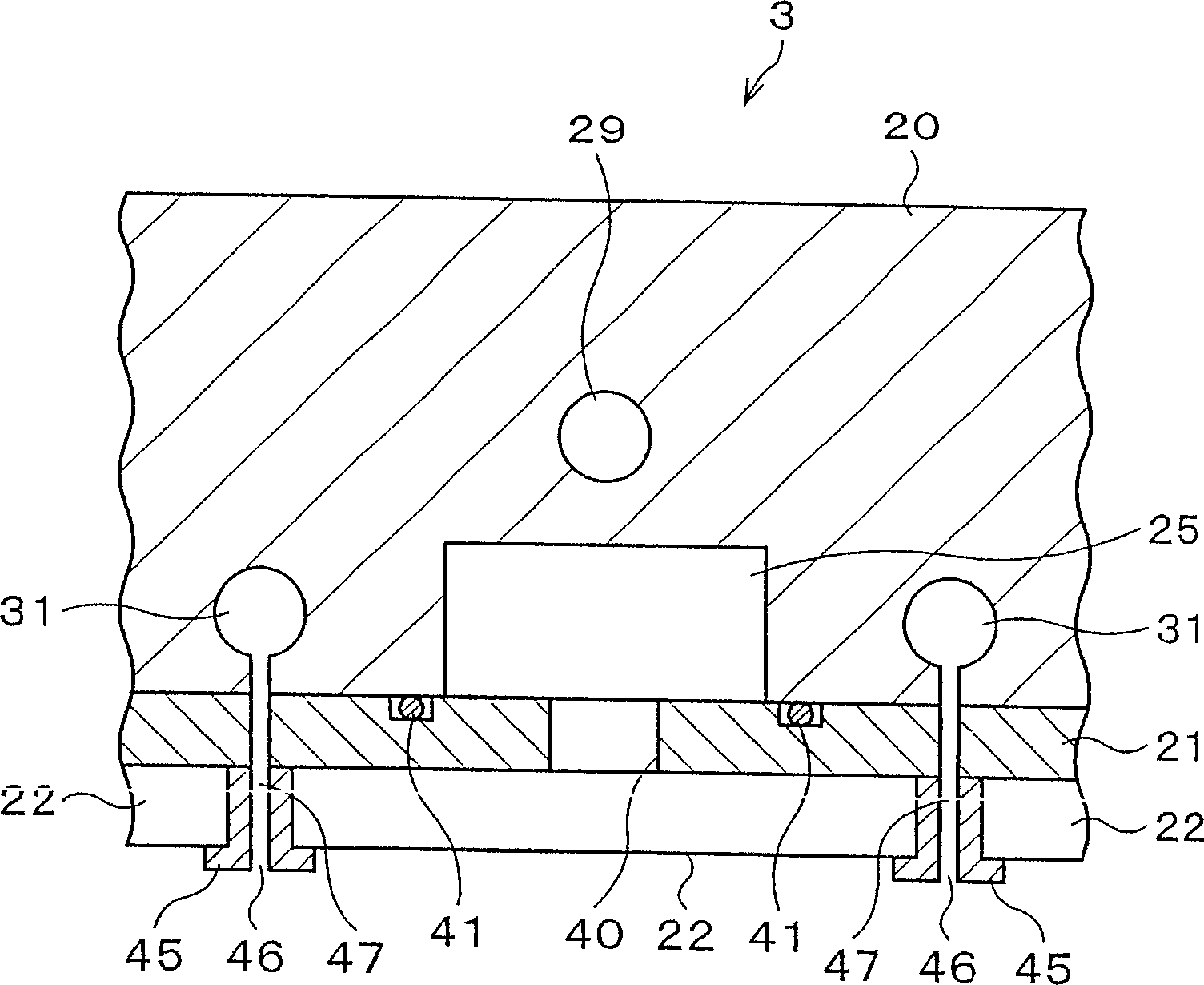

[0019] Hereinafter, an embodiment of the present invention will be described based on a plasma processing apparatus 1 that performs CVD (Chemical Vapor Deposition) processing as an example of plasma processing. figure 1 It is a vertical cross-sectional view showing a schematic configuration of the plasma processing apparatus 1 according to the embodiment of the present invention. figure 2 It is a bottom view showing the arrangement of a plurality of dielectric bodies 22 supported on the lower surface of the lid body 3 included in the plasma processing apparatus 1 . image 3 It is a partially enlarged longitudinal sectional view of the cover body 3 .

[0020] The plasma processing apparatus 1 includes a bottomed cuboid processing container 2 with an open top, and a cover 3 that closes the processing container 2 . The processing container 2 and the cover body 3 are made of aluminum, and both are grounded.

[0021] A susceptor 4 is provided inside the processing container 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com