Method for producing packaging paper board and its producing device

A technology for packaging cardboard and production method, which is applied in papermaking, papermaking machine, wet end of paper machine, etc., to achieve the effect of improving efficiency, reducing cost, and improving flat pressing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

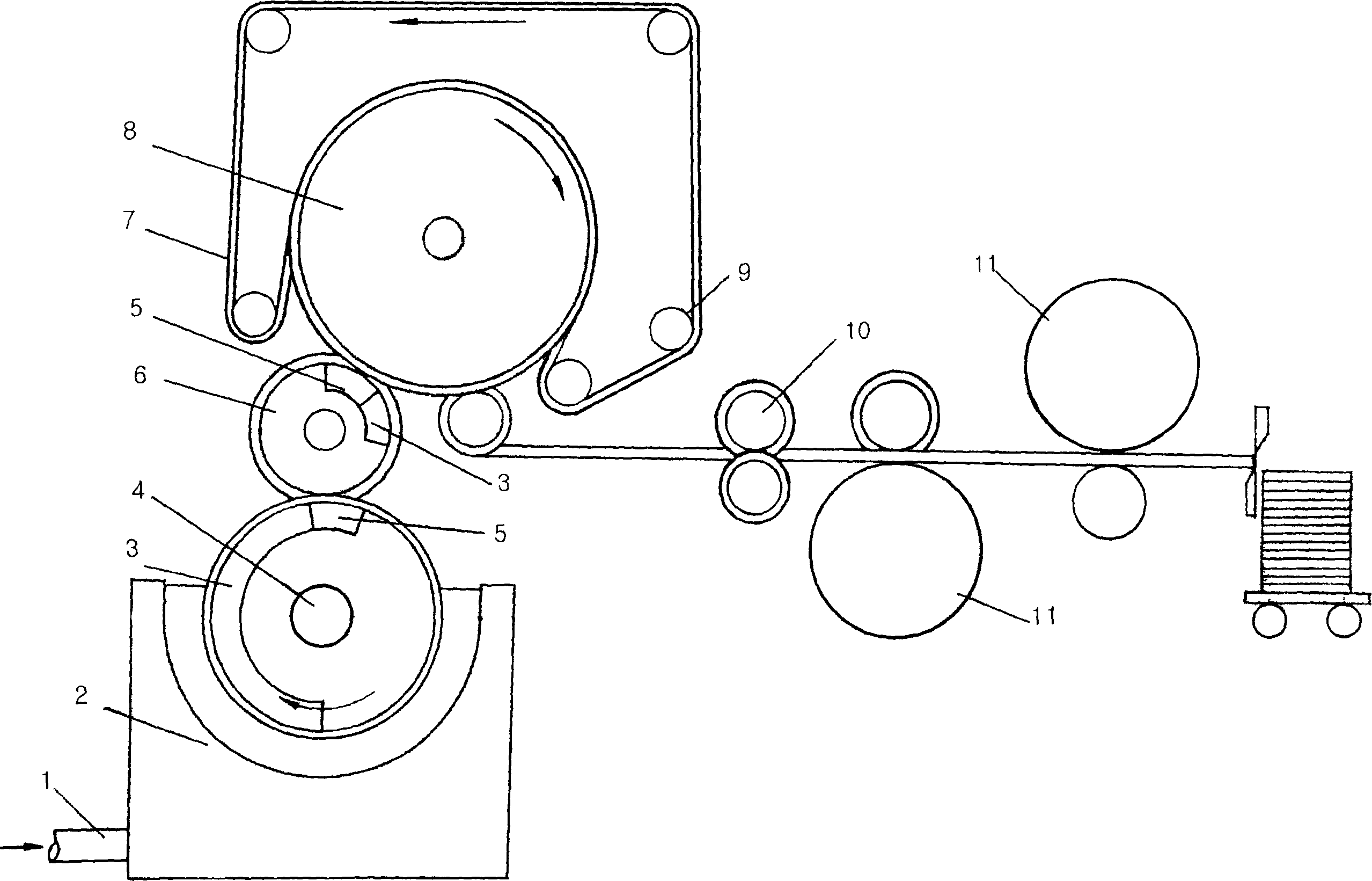

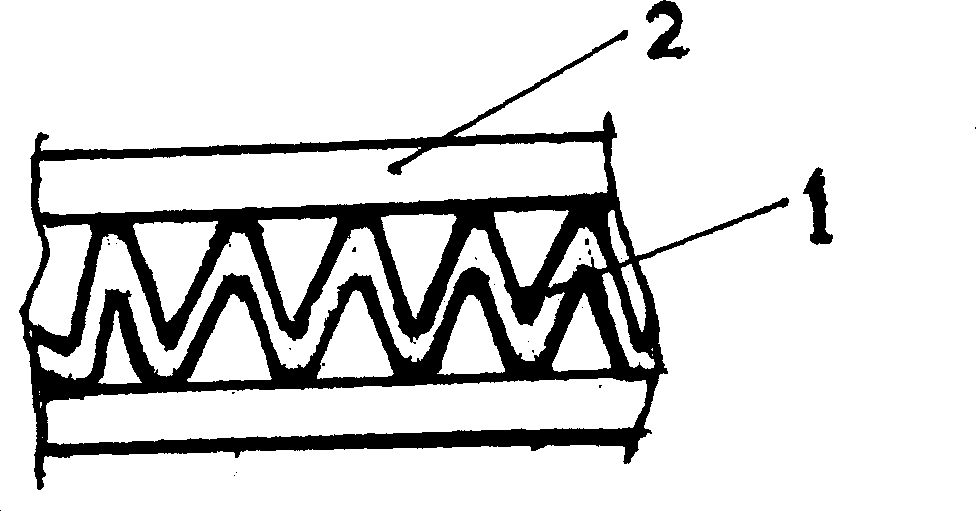

[0026] The object of the present invention is to provide a production method of packaging cardboard and its production equipment. It is characterized in that: the production method of the packaging cardboard is a method for producing corrugated cardboard by molding at one time, and the specific production steps are as follows:

[0027] 1) Molding:

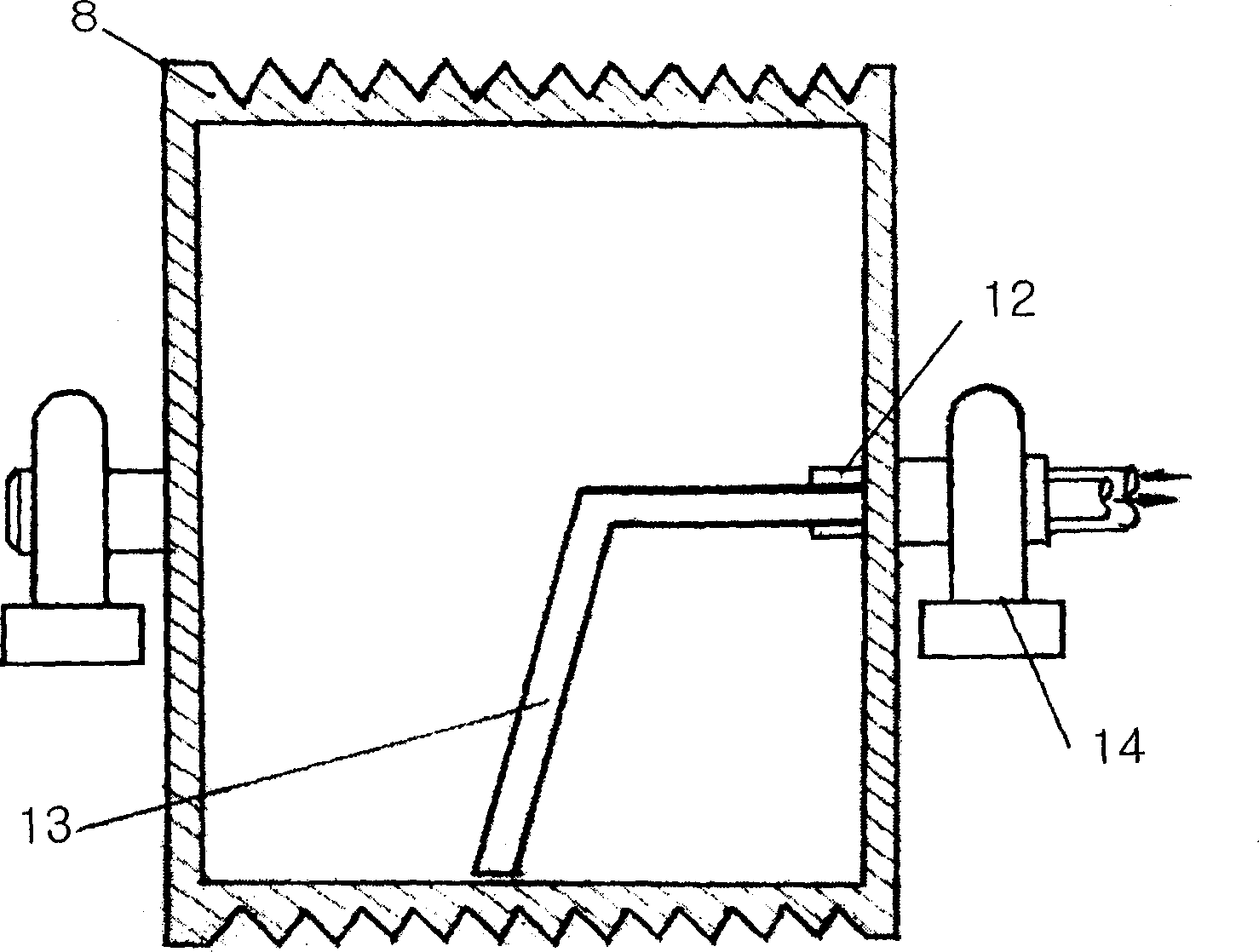

[0028] exist figure 1 In the structural schematic diagram of the one-time forming cardboard equipment shown, the prepared waste paper pulp or straw pulp is adjusted to a concentration of 1% by weight, and is sent from the feed pipe 1 to the slurry tank 2 of the forming part of the production line. Shaper 4 is installed on slurry tank 2 tops, and bearing 14 supports are arranged on both sides (as figure 2 Shown), it is as the criterion that 60~70% of the circumference of the former is submerged in the slurry tank 2. The take-up roller 6 is installed between the former 4 and the drier 8, respectively abutting against them, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com