Capacitance microwave power sensor

A microwave power and sensor technology, applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., can solve the problems of microwave signal consumption, etc., and achieve the effects of improved compatibility and repeatability, good linearity, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

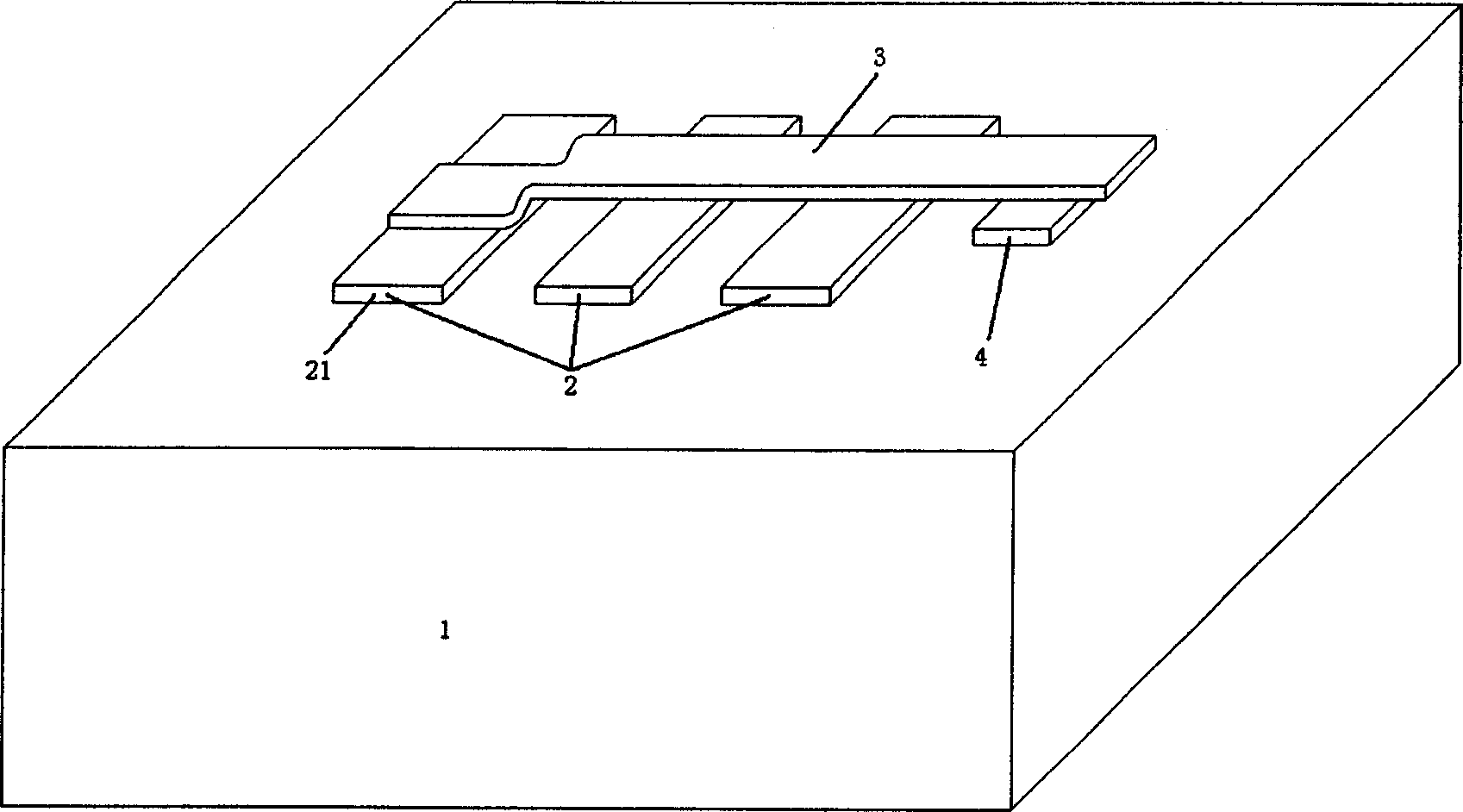

[0012] The capacitive microwave power sensor of the present invention takes GaAs or Si substrate 1 as substrate, is provided with coplanar waveguide 2 on GaAs or Si substrate 1, connects on coplanar waveguide ground wire 21 and is perpendicular to coplanar waveguide 2 A cantilever beam 3 is provided, the cantilever beam 3 is suspended above the coplanar waveguide 2, and a sensing electrode 4 is placed under the end of the cantilever beam 3. The height of the cantilever beam 3 is related to the sensitivity and reflection coefficient of the device, so the height of the cantilever beam 3 is selected to be 1-3 microns.

[0013] The manufacturing process of the capacitive microwave power sensor is fully compatible with the standard Si process or GaAs MMIC process.

[0014] The structure of the capacitive microwave power sensor is different from the previous online microwave power sensor based on MEMS technology. This structure uses the cantilever beam to induce the displacement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com