A highly effective plaque-removing whitening toothpaste and method for making same

A toothpaste, high-efficiency technology, applied in high-efficiency stain-removing whitening toothpaste and its manufacturing field, can solve the problems of easy damage to tooth enamel and gums, inability to use frequently, and teeth blackening, etc., to achieve strong stain-removing cleaning power and foaming performance Good, good cleaning and decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] A high-efficiency stain-removing and whitening toothpaste, which is prepared from the following raw materials according to their weight%:

[0098] Nano ultrafine silica 30

[0099] Natural glycerin 10

[0100] Sorbitol 21

[0101] Hydroxymethyl cellulose 1.2

[0102] Hydroxyethyl cellulose 0.2

[0103] Sodium Laurel Sarcosinate 1.8

[0104] Compound enzyme 0.05

[0105] Rice bran wax whitening particles 2.5

[0106] EDTA-2Na 0.1

[0107] Zinc citrate 0.8

[0108] Propolis 0.35

[0111] D-Panthenol 0.5

[0112] Spice 0.8

[0113] Deionized water 30

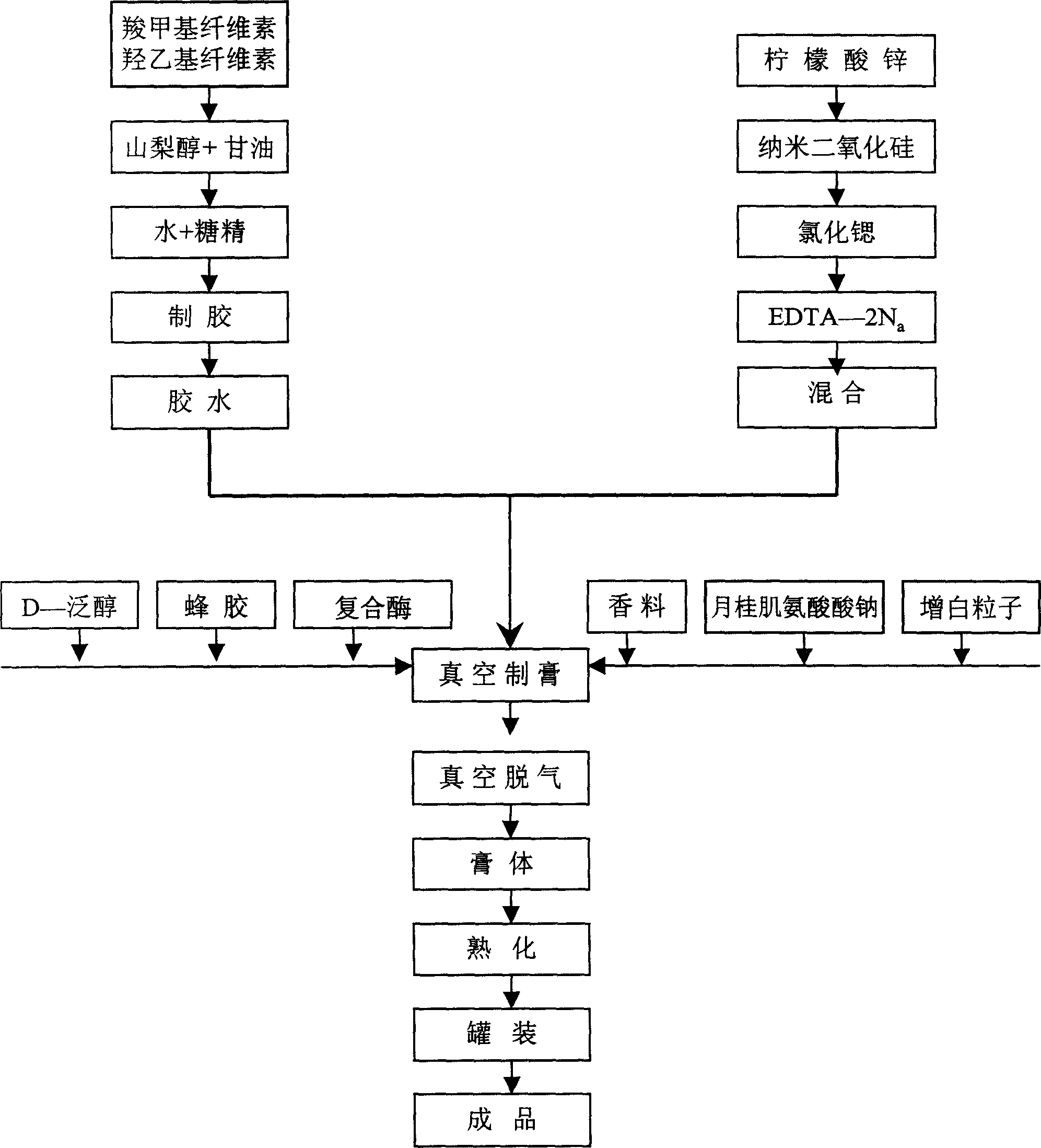

[0114] The present invention adopts advanced three-in-one vacuum paste making equipment and process preparation, and its production process flow chart is as follows figure 1 As shown, the operation steps of this embodiment are as follows:

[0115] First, the above-mentioned raw materials are mixed according to their weight%, and then the carboxymethyl cellulose and hy...

Embodiment 2

[0117] A high-efficiency stain-removing and whitening toothpaste, which is prepared from the following raw materials according to their weight%:

[0118] Nano ultrafine silica 35

[0119] Natural glycerin 12

[0120] Sorbitol 26

[0121] Hydroxymethylcellulose 1.0

[0122] Hydroxyethyl cellulose 0.15

[0123] Sodium Laurel Sarcosinate 2

[0124] Compound enzyme 0.03

[0125] Jojoba wax whitening particles 3

[0126] EDTA-2Na 0.15

[0127] Zinc citrate 1.7

[0128] Propolis 0.5

[0130]Sodium saccharin 0.25

[0131] D-Panthenol 0.6

[0132] Spice 1

[0133] Deionized water 18

[0134] The manufacturing process of this embodiment is the same as that of the first embodiment.

Embodiment 3

[0136] A high-efficiency stain-removing and whitening toothpaste, which is prepared from the following raw materials according to their weight%:

[0137] Nano ultrafine silica 40

[0138] Natural glycerin 15

[0139] Sorbitol 30

[0140] Hydroxymethyl cellulose 0.8

[0141] Hydroxyethyl cellulose 0.1

[0142] Sodium Laurel Sarcosinate 2.5

[0143] Compound enzyme 0.1

[0144] Silica whitening particles 3

[0145] EDTA-2Na 0.2

[0146] Zinc citrate 2.8

[0147] Propolis 1.5

[0148] Strontium chloride 0.8

[0149] Sodium saccharin 0.3

[0150] D-Panthenol 0.8

[0151] Spice 1.2

[0152] Deionized water 3

[0153] The manufacturing process of this embodiment is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com