Resonant-type micro-mechanical optic fiber gyroscope

A mechanical gyro and resonance technology, which is applied in the direction of speed measurement, gyroscope/steering sensing equipment, and measuring devices, etc., can solve the problems of micro-mechanical gyro sensitivity and insufficient resolution, and achieve easy digital signal processing and improve sensitivity. , the effect of avoiding the influence of noise interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

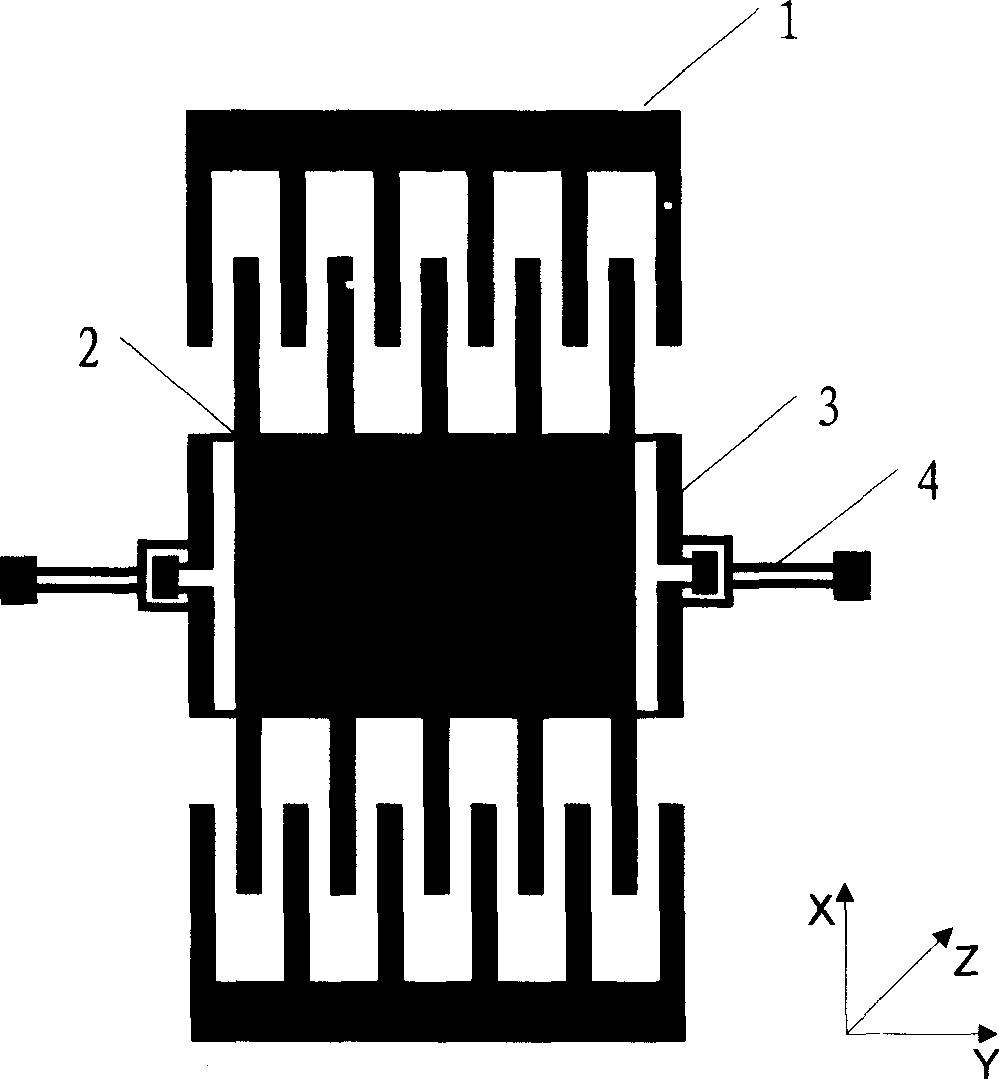

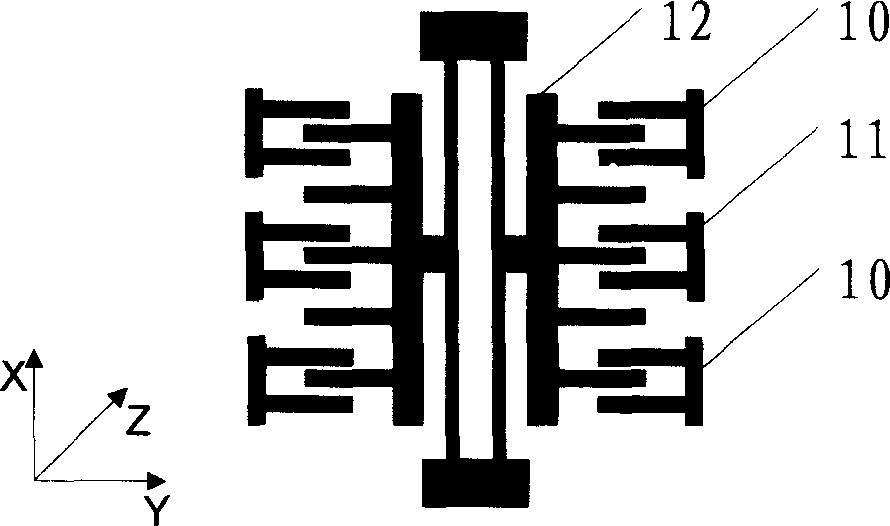

[0016] Such as figure 1 As shown, the present invention is composed of a comb-shaped interdigital driver 1, a flat mass 2, a lever amplification mechanism 3 and a double-ended tuning fork resonator 4. The flat mass 2 is in the middle position and is suspended on the base through a support beam. Its x direction Two comb-shaped interdigital actuators 1 fixed on the base are placed symmetrically on the upper side, and two pairs of lever amplification mechanisms 3 are arranged symmetrically in the y direction, and are connected to two double-ended tuning fork resonators (DETF) 4 on the outside.

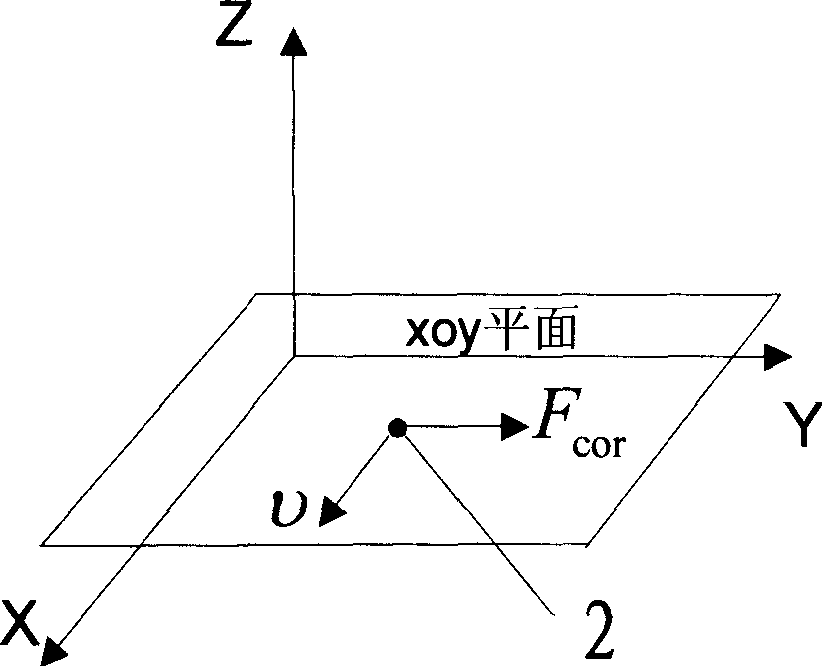

[0017] Such as figure 2 As shown, the flat mass 2 is a thin solid cubic structure with a length and width of 100-1000 μm and a thickness of 70-80 μm, which is fixed on the xoy plane of the rotating coordinate system. After being driven by the electrostatic force, it will move along the x-axis direction at a speed υ relative to the rotating coordinate system, and the rotating coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com