Heat-shrinkable polyester film and heat-shrinkable polyester film roll

A heat shrinkable, polyester technology, applied in the field of film rolls, can solve the problems of large changes in heat shrinkage characteristics, pattern deformation, increase in defect rate, etc., and achieve the effect of excellent heat shrinkage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0256] 100 mol% of dimethyl terephthalate is used as polycarboxylic acids, and 100 mol% of ethylene glycol, which is 2.2 times (molar ratio) relative to polycarboxylic acids, is used as polyhydric alcohols, and is added to the esterification reaction tank, while adding As a catalyst, 0.04 mol% of antimony trioxide with respect to the polycarboxylic acid and 81 ppm of magnesium acetate tetrahydrate with respect to the formed polyester in terms of magnesium atoms were heated to 230°C while stirring, and the ester was carried out under normal pressure. The exchange reaction lasted for 120 minutes, and the end point of the transesterification reaction was defined as the point at which a predetermined amount of methanol was distilled off. After the transesterification reaction was completed, 58 ppm of trimethyl phosphate was added in terms of P atom conversion relative to the formed polyester, and the temperature was raised to 280° C. while depressurizing for 85 minutes, and the pol...

Synthetic example 2~7

[0258] Polyesters B to G shown in Table 1 were synthesized in the same manner as in Synthesis Example 1. In Synthesis Example 2 and Synthesis Example 3, polyesters B and C were obtained using antimony trioxide in which the amount of Sb atoms relative to the polyester was 160 ppm as a polymerization catalyst. On the other hand, in Synthesis Example 4, polyester D was obtained by using tetrabutoxytitanium having 90 ppm of Ti atoms relative to the polyester as a polymerization catalyst. In Synthesis Example 6, polyester F was obtained by using cobalt acetate tetrahydrate having 20 ppm of Mg atoms relative to the polyester and tetrabutoxytitanium having 15 ppm of Ti atoms relative to the polyester as a polymerization catalyst. In Synthesis Example 7, polyester G was obtained using the same polymerization catalyst as in Synthesis Example 1.

[0259] As for the lubricant, 0.7% by mass of silica with an average particle diameter of 1.8 μm (“Sysilia 350” manufactured by Fuji Silysia ...

Synthetic example 8~14

[0278] Polyesters A to G were synthesized in the same manner as in Synthesis Example 1 except that polyester A and polyester E were not blended with silica. The compositions of these polyesters are the same as polyesters A to G in Table 1.

[0279] Experiment 12

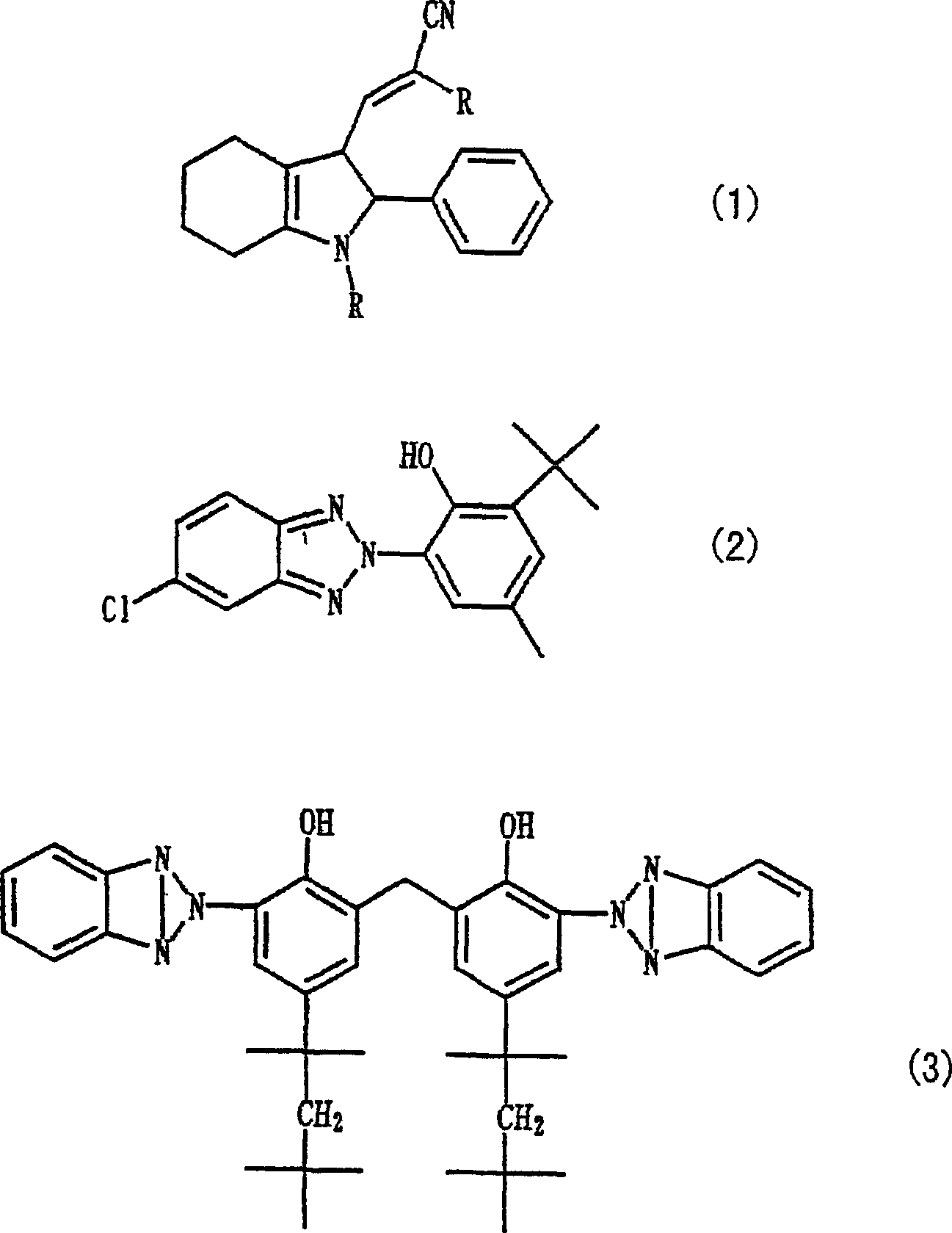

[0280] A 3-layer laminated polyester-based film No. 12 consisting of two outer layers and a center layer was produced. In the center layer, each tablet of polyester A, polyester B and polyester D which were pre-dried respectively was mixed in the ratio shown in Table 6, and an ultraviolet ray blocking agent (Ciba Specialty Chemicals Inc. "チヌビン (registered trademark) 326" manufactured by the U.S. Co., Ltd. Co., Ltd. Co., Ltd. Co., Ltd. Co., Ltd. Co., Ltd. Co., Ltd. Co., Ltd.) Co., Ltd.) made the ultraviolet blocking agent account for 1% by mass in the total of 100% by mass of the mixed polyester and the ultraviolet blocking agent. In addition, the two outer layers also use a mixture of mixed polyester and UV blockin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com