Electron emitting element, electron emitting device, display and light source

A technology of electron injection and components, applied in the field of light sources, can solve the problems of high manufacturing cost and complicated panel manufacturing process, and achieve the effects of reducing product cost, improving straightness, and realizing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

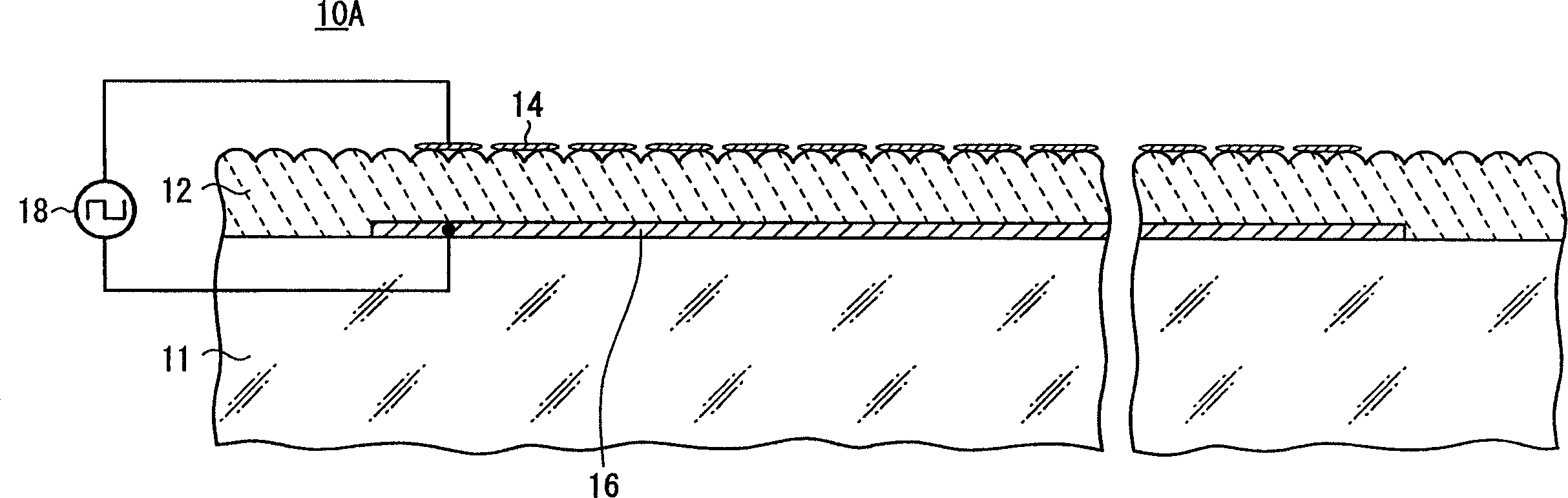

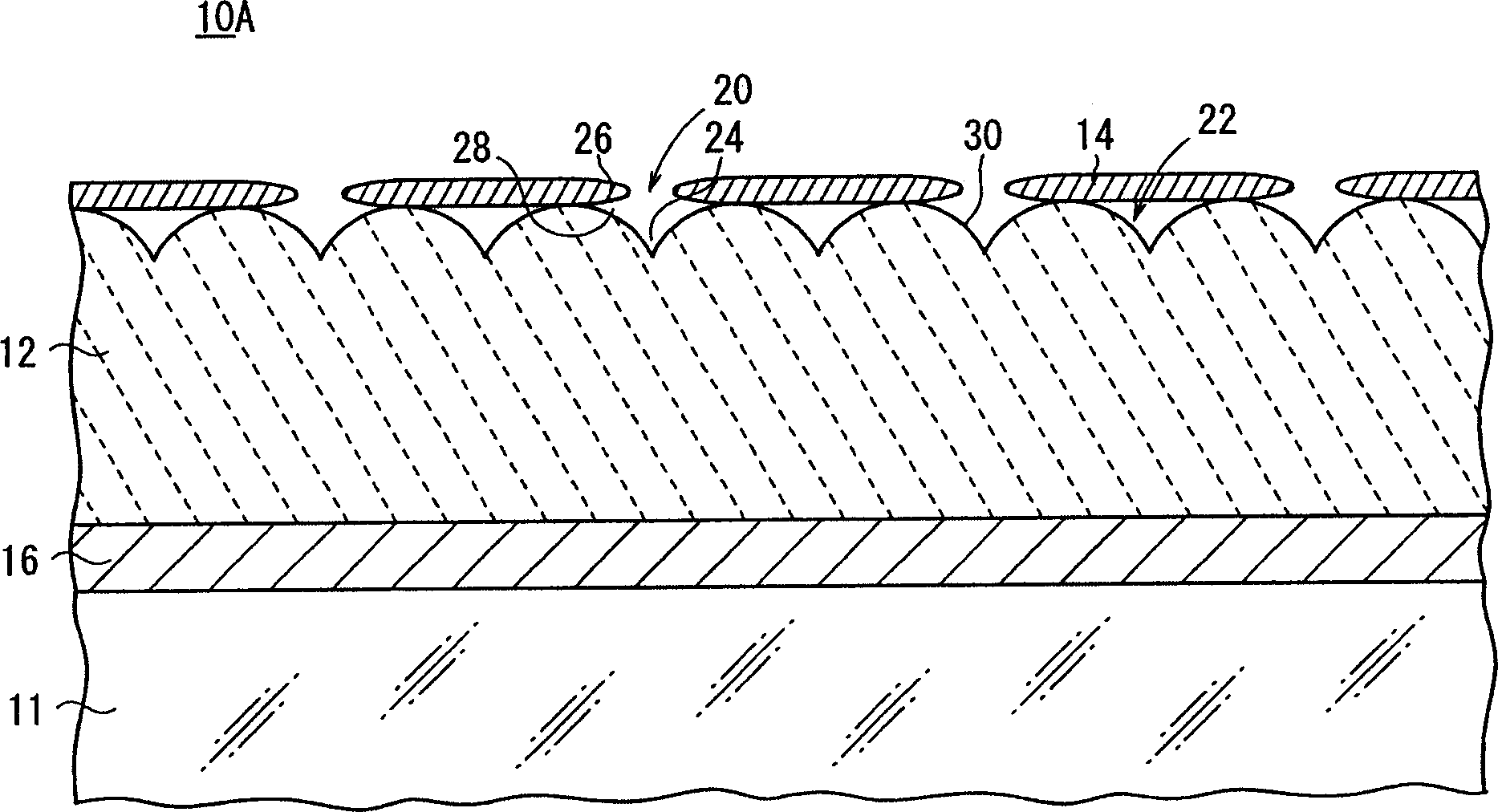

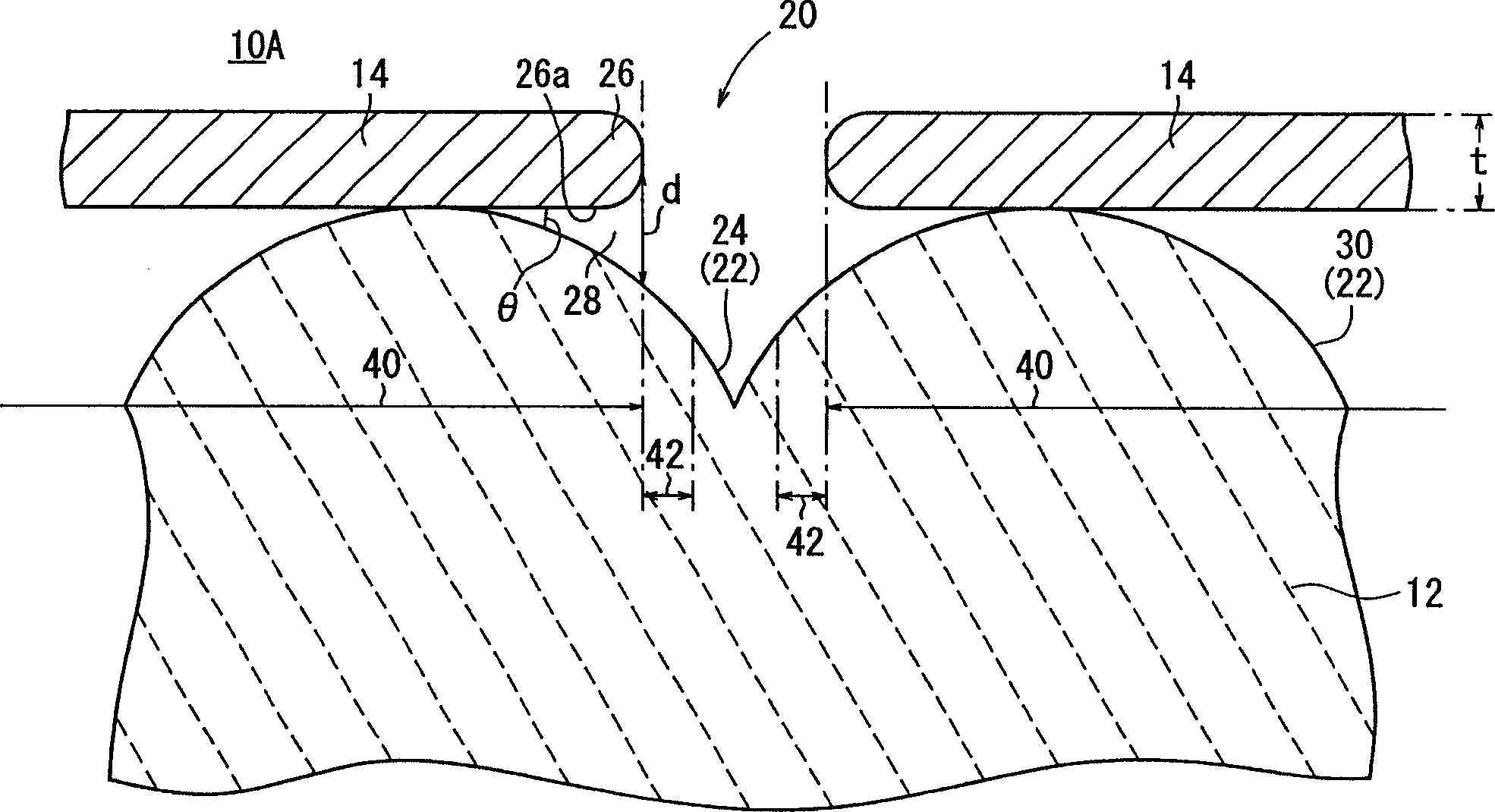

[0076] Refer below Figure 1 to Figure 40 Embodiments of the electron emission device of the present invention will be described.

[0077] First, the electron injection device of this embodiment can be applied to an electron beam irradiation device, a light source, use in place of LEDs, an electronic component manufacturing device, and an electronic circuit component in addition to the use as a display.

[0078]The electron beam in the electron beam irradiation device is superior in absorbing performance at high energy compared with the ultraviolet rays in the ultraviolet irradiation device which is widely used at present. Examples of use include curing insulating films when superimposing wafers in semiconductor devices, uniformly hardening printing inks during printing and drying, and packaging medical devices in boxes for sterilization.

[0079] Applications of light sources include planar light sources such as backlights for liquid crystal displays, and light sources for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com