Steel for forging having excellent hydrogen embrittlement resistance and crankshaft

A hydrogen embrittlement-resistant technology for forging, which is applied in the field of forging steel, can solve the problems that hydrogen embrittlement cannot be completely prevented, it is difficult to expect high purification degree fatigue strength, the degree of purification of finished steel and mechanical properties, fatigue strength deterioration, etc. Achieve high fatigue strength, lightweight fatigue strength, and excellent hydrogen embrittlement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

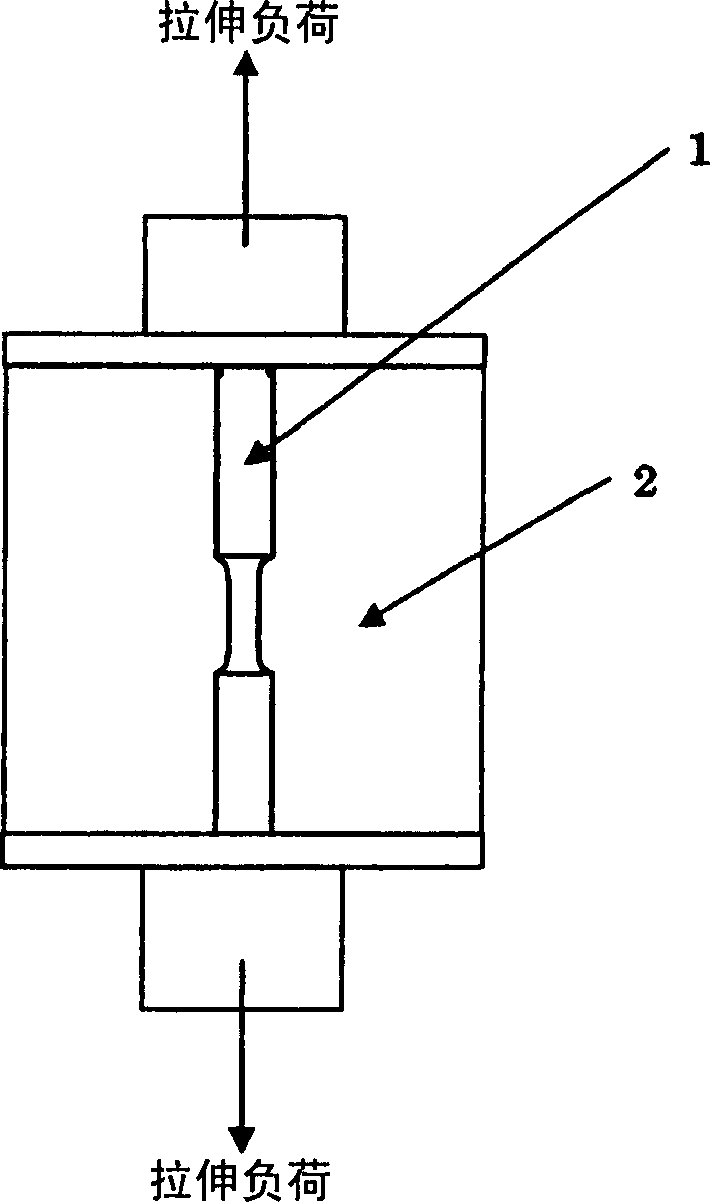

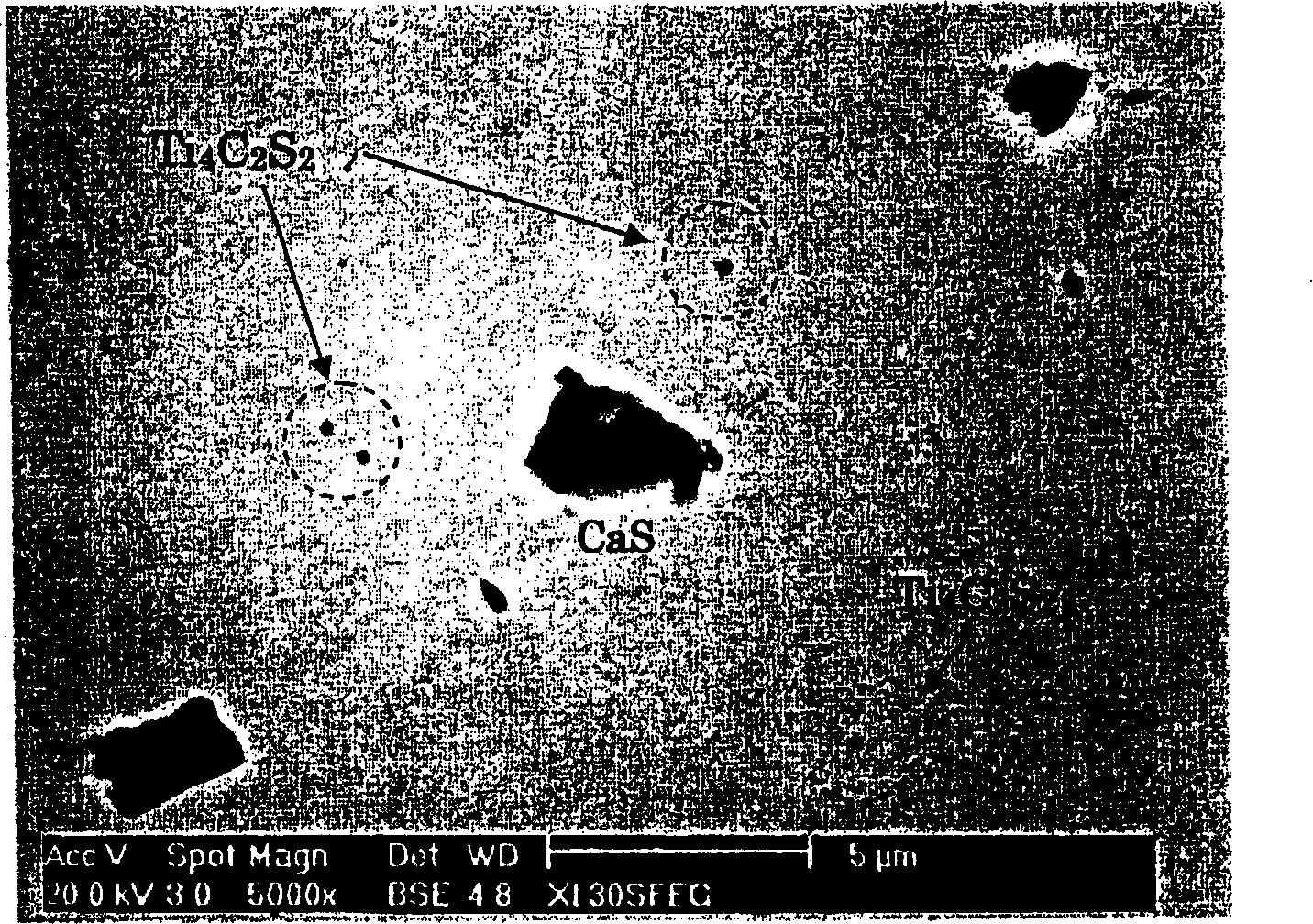

[0026] The steel for forging excellent in hydrogen embrittlement resistance of the present invention is characterized in that the component composition of the steel is limited, and the characteristic values such as the shape, size, and number of inclusions in the steel are relatively adjusted.

[0027] First, the component composition of steel will be described.

[0028] By containing C: 0.2 to 0.6%, the hardenability and strength of the steel can be improved, and 0.2% or more is necessary for this, but if it is more than 0.6%, the toughness of the steel deteriorates and V segregation is promoted on the contrary. It may be more preferably in the range of 0.3 to 0.5%.

[0029] Containing Si: 0.1 to 0.4% is to expect the strength improvement effect of the steel. In order to ensure sufficient strength, 0.1% or more is required. If it is too much, V segregation will become prominent instead, hindering the purification of steel, so it is 0.4% or less , more preferably 0.3% or le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com