Constant power control method and device of electronic ballast

A technology of constant power control and electronic ballast, which is applied in the direction of lighting devices, electric light sources, electrical components, etc., and can solve the problems of complex circuits and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

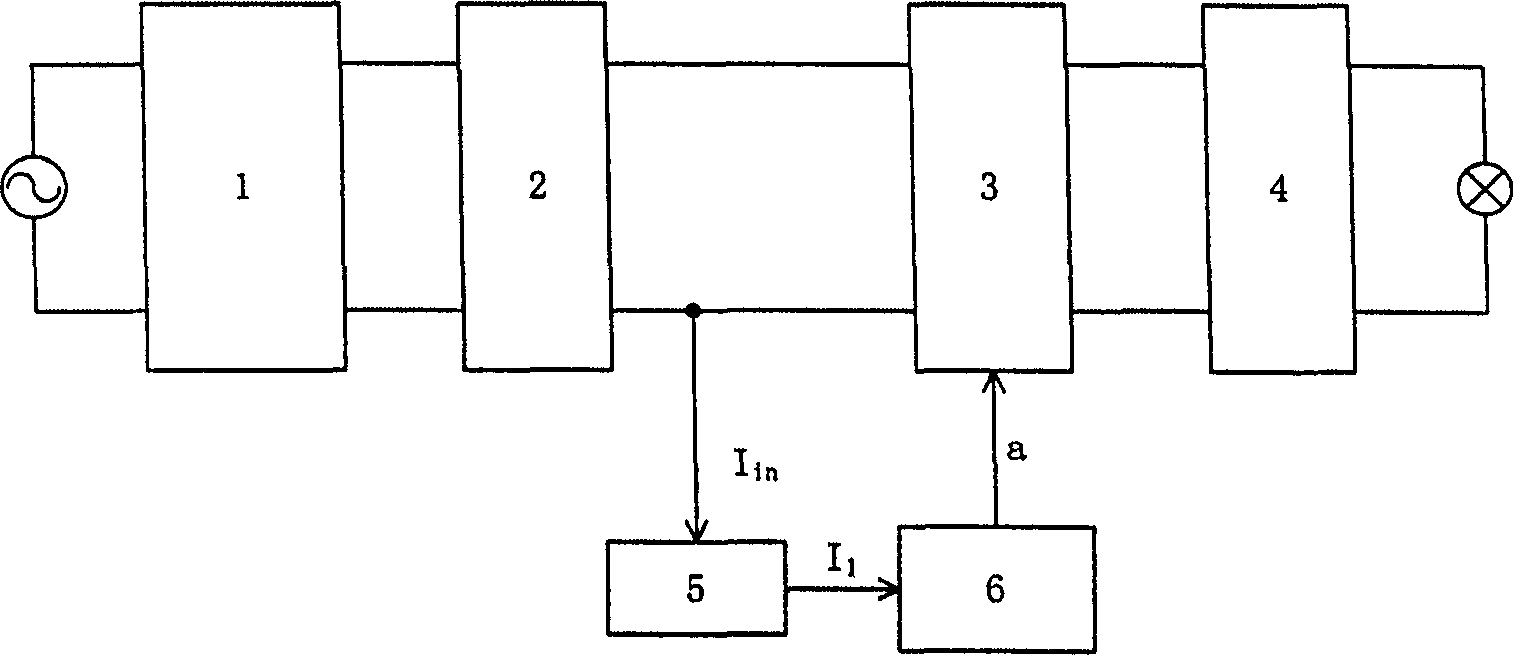

[0024] refer to figure 1 The main power part of the electronic ballast includes an electromagnetic interference (EMI) filter unit 1 , an AC / DC unit 2 , a DC / DC unit 3 and a DC / AC unit 4 . The input is AC power. The DC / DC unit 3 controls the current of the high-intensity gas discharge lamp, and the specific control method is as follows: the current detection unit 5 detects the output current I of the AC / DC unit 2 in , after transformation, the variable current I is obtained 1 ; In the control unit 6, the variable current I 1 Compared with the preset current value, the control signal a of the DC / DC unit 3 is generated; the DC / DC unit 3 generates the driving signal of its switch tube according to the control signal a, and realizes the control of the DC / DC unit 3. The input The current is equal to the preset current value.

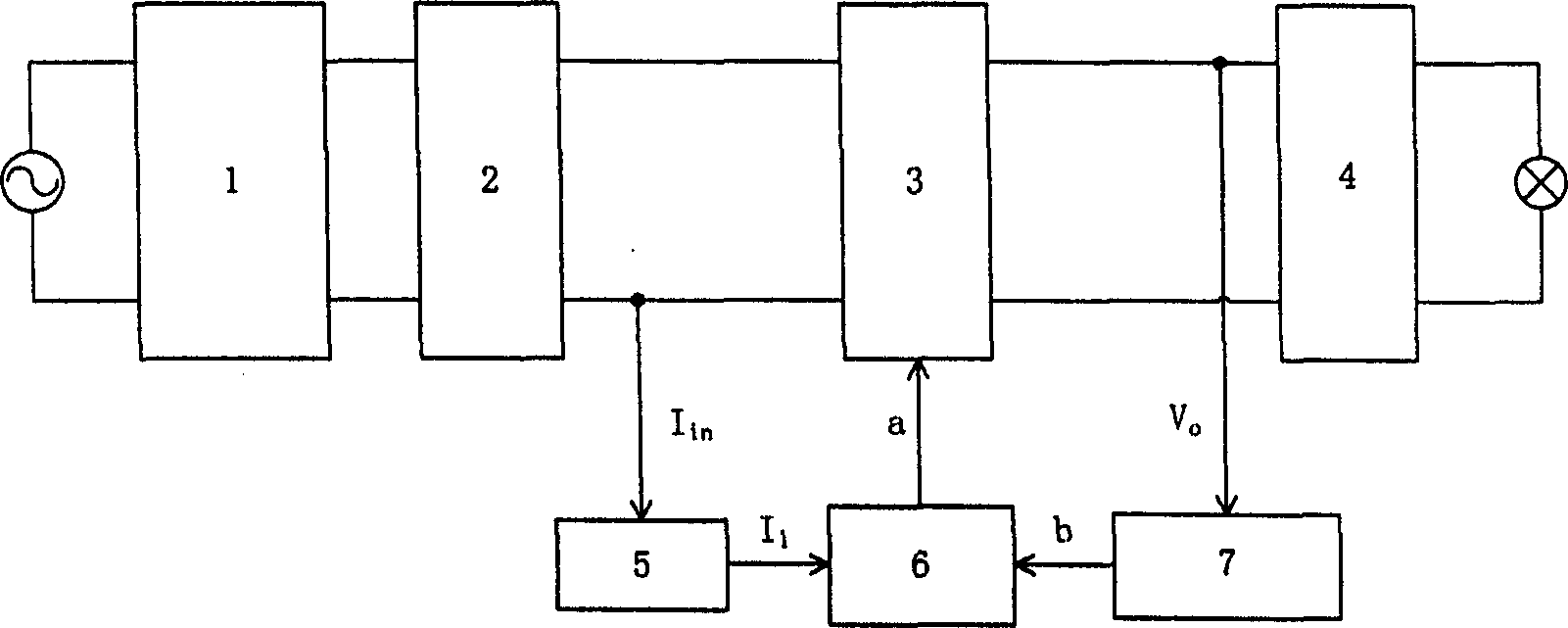

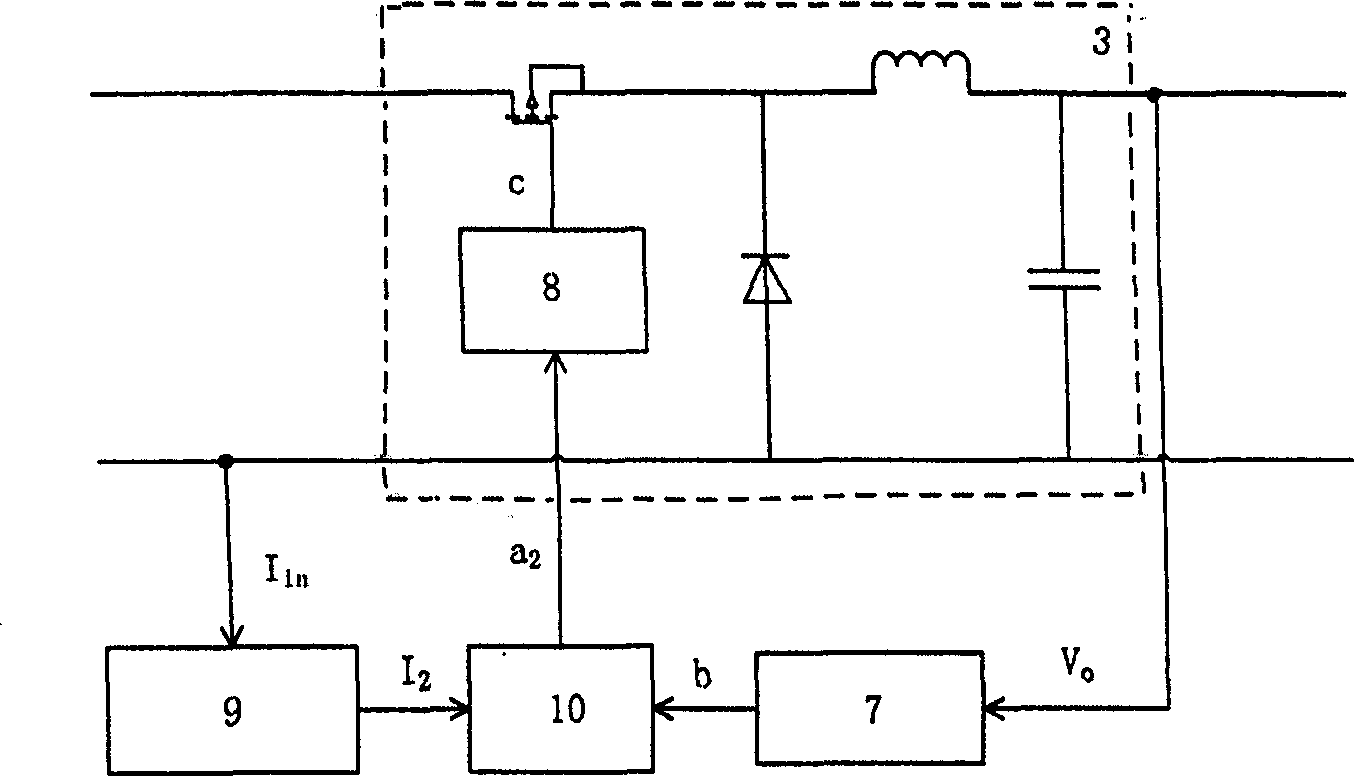

[0025] refer to figure 2 ,and figure 1 Compared with it, an output voltage detection and transformation unit 7 is added, and the purpose of voltage det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com