Housing cup for an electronic component with integrated cooling body

A technology for electronic components and cooling bodies, applied in electrical components, resistor parts, capacitor parts and other directions, can solve the problems of high installation costs of cooling bodies, increase in volume of electronic devices, high installation costs, etc., and achieve higher manufacturing costs. The effect of eliminating additional costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

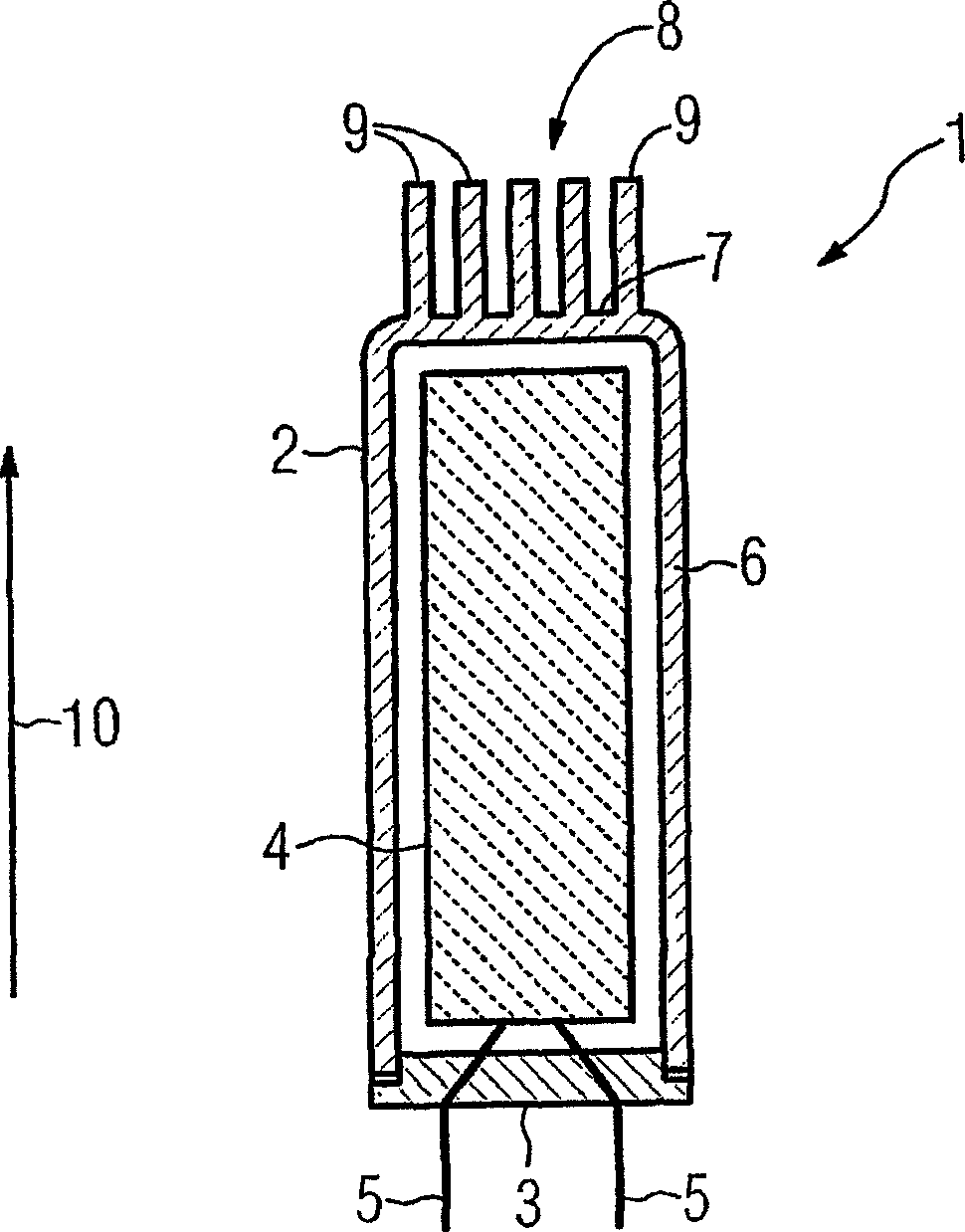

[0029] figure 1 The housing of the electronic device 1 is shown schematically, which comprises a cylindrical cup 2 closed by a housing cover 3 . Inside the housing formed by the cup 2 and the housing cover 3 is an electronic component 4 , which is contactable via two contacts 5 in the form of wires leading out through the housing cover 3 .

[0030] The cup 2 has a tubular side wall 6 which is closed on the front side opposite the housing cover 3 by a cup base 7 integral with the side wall 6 . The cup bottom 7 forms the basic surface of the heat sink 8 integrated with the cup 2 . The heat sink 8 also includes a number of projections 9 which stand up on the outer surface of the cup base 7 in the axial direction 10 of the cup 2 and are at a certain distance from one another.

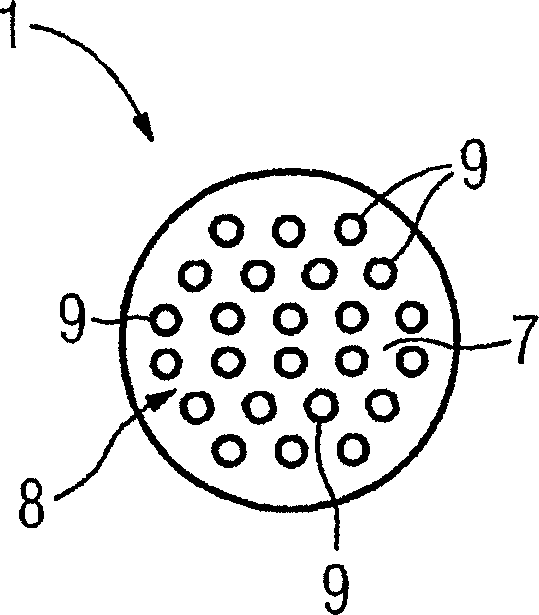

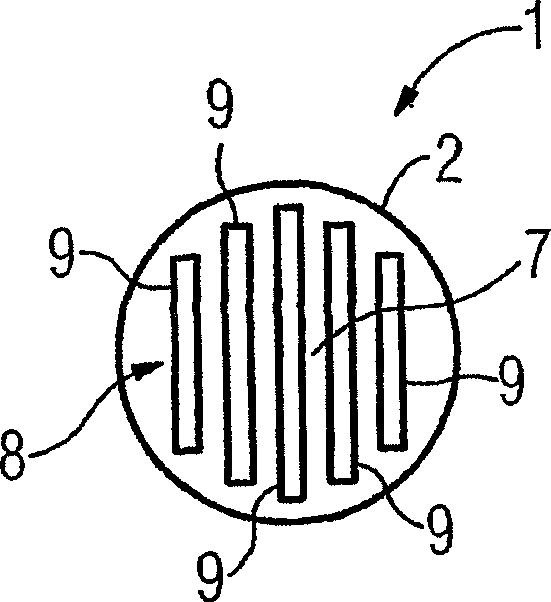

[0031] figure 2 and 3 Two different configurations of the projections 9 of the cup bottom 7 as viewed towards the axial direction 10 are shown. according to figure 2 The protrusions 9 are configured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com