Insulated gate semiconductor device, protection circuit and their manufacturing method

A technology of insulating gate type and manufacturing method, which is used in semiconductor/solid-state device manufacturing, emergency protection circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., can solve problems such as limitations, and achieve high sealing performance, reduce on-resistance, and ensure hermeticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

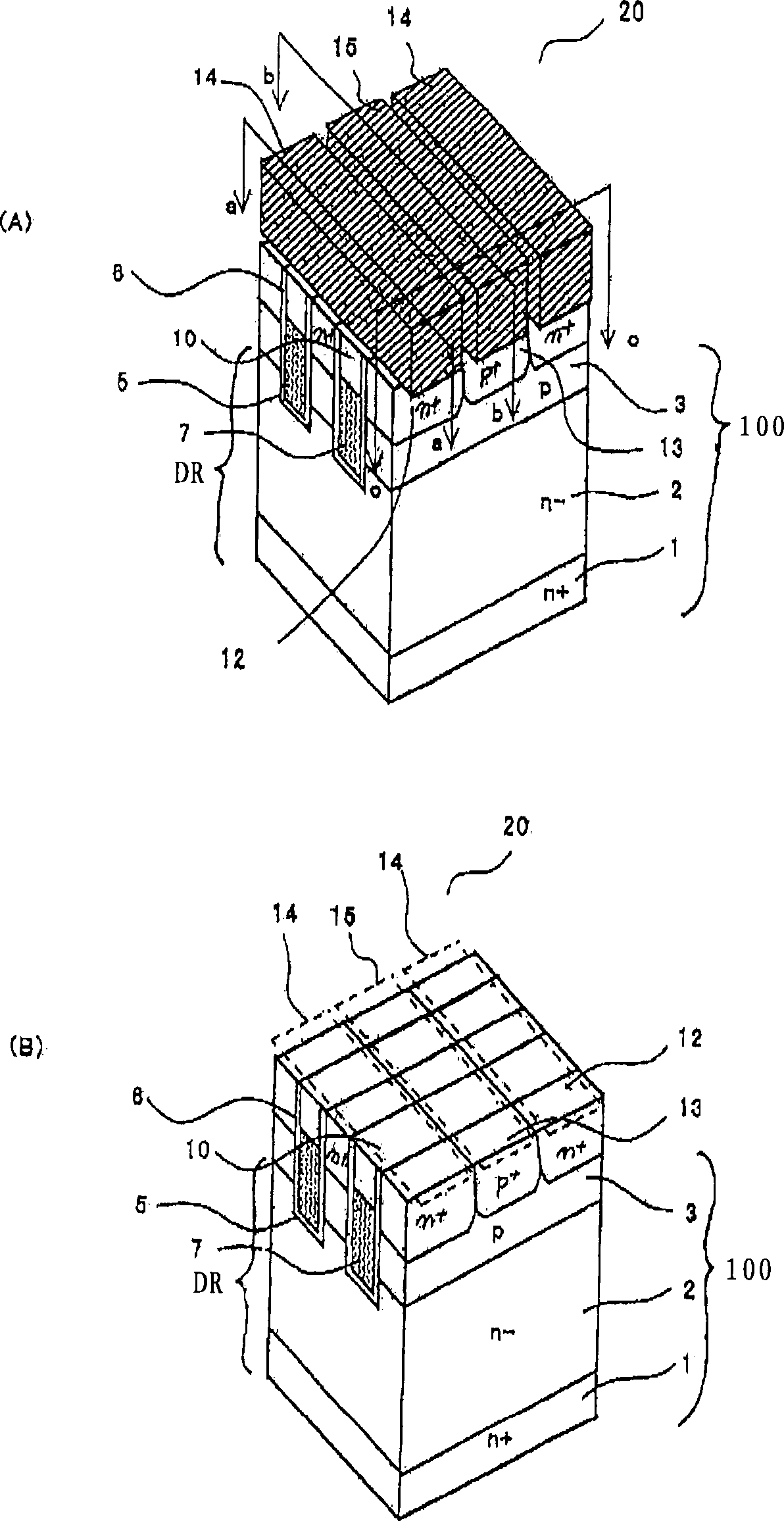

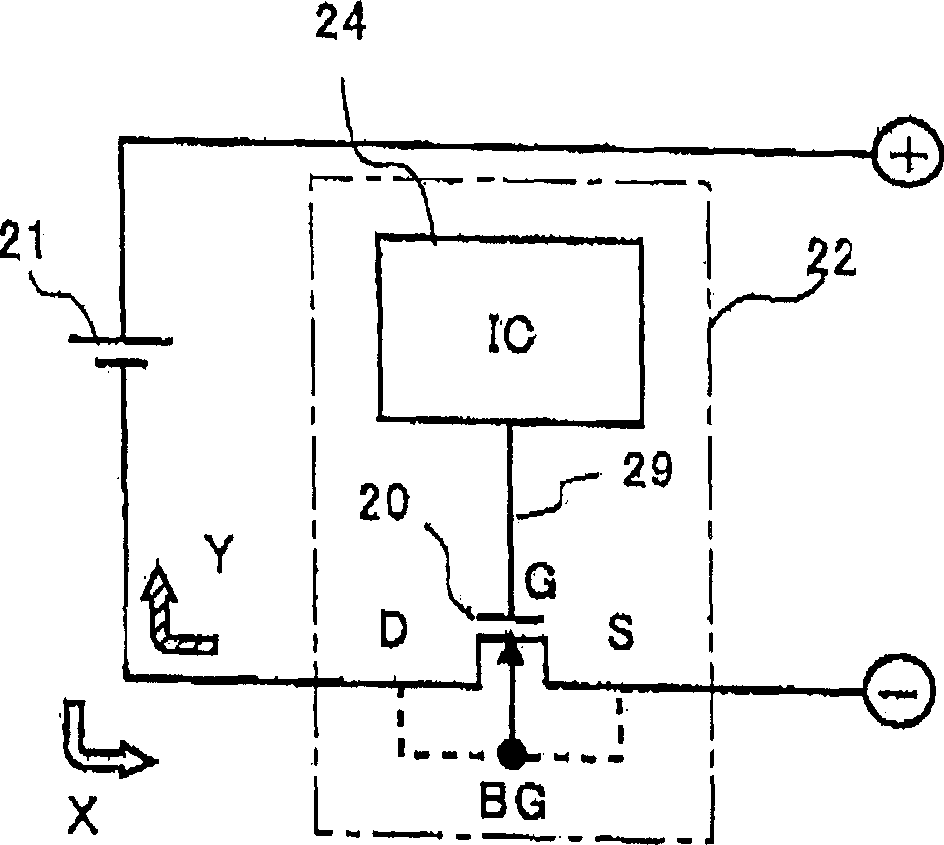

[0087] refer to Figure 1 to Figure 15 , the embodiment of the present invention will be described by taking a MOSFET with an n-channel layer trench structure as an example.

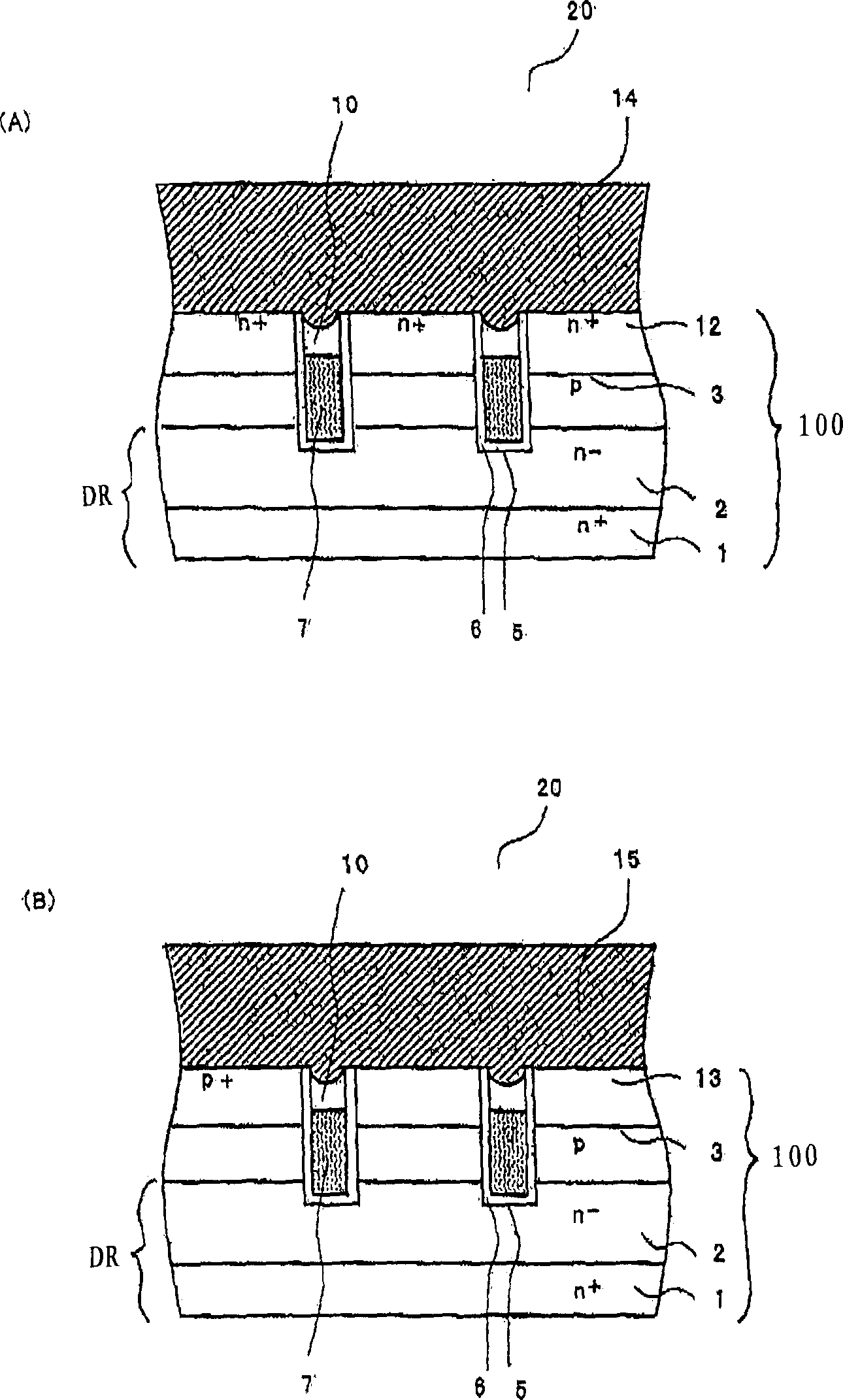

[0088] First, refer to Figure 1 to Figure 11 The first embodiment will be described. figure 1 It is a perspective view showing a MOSFET. figure 1 (A) is a figure in which the first and second electrode layers are arranged, figure 1 (B) is a diagram showing a region where the first and second electrode layers are arranged by dotted lines. in addition, figure 2 is a cross-sectional view, figure 2 (A) is figure 1 (A) a-a line profile, figure 2 (B) is figure 1 (A) The b-b line profile.

[0089] MOSFET20 consists of semiconductor substrate 1, semiconductor layer 2, channel layer 3, trench 5, gate insulating film 6, gate electrode 7, source region 12, body region 13, interlayer insulating film 10, first electrode layer 14. The second electrode layer 15 and the drain electrode 16 are formed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com