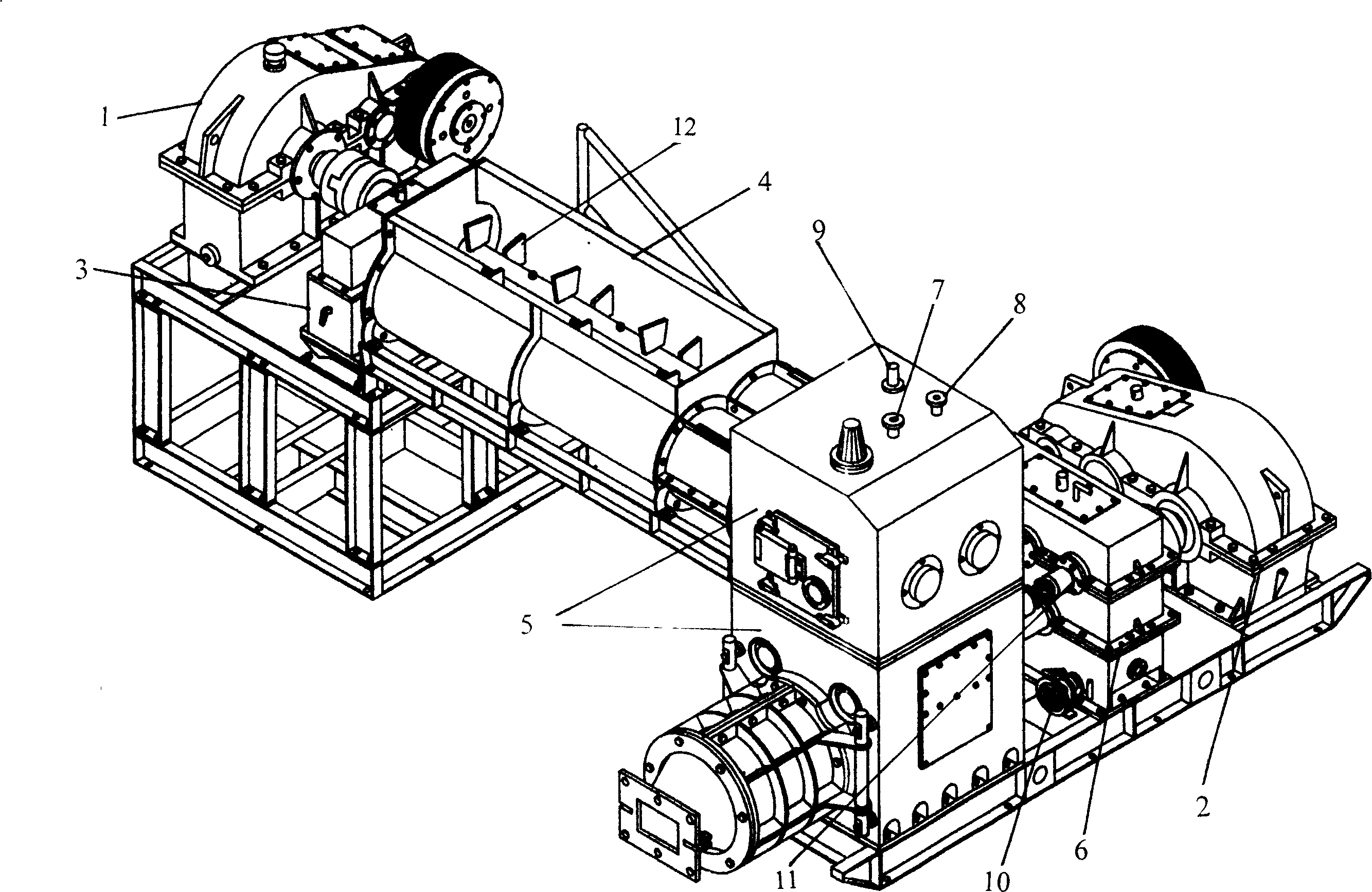

Two-stage vacuum brick and tile extruding machine

A technology of vacuum machine and extruder, which is applied in the improvement field of brick extruder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] It can be seen from the figure that this two-stage vacuum tile extruder is driven by two motors through an axial pneumatic clutch to drive the split reducers (1) and (2), and the horizontal reducer (1) directly passes through the transmission box (3) Drive the rotating shaft in the mixing tank (4) for mixing and extruding. The first stage of this large two-stage vacuum machine (5) is connected to the mixing tank (4). It is also arranged horizontally and a longitudinal reducer (2) The transmission box (6) is equipped with a universal joint (11) mechanism. Behind them is connected the other stage of the two-stage vacuum machine (5), which is arranged in the longitudinal direction. They drive the forming and extruding devices, and the mixing barrel ( 4) The stirring knife (12) inside is made by 16 manganese casting process, and the spiral is also made by 16 manganese casting process, and through special mechanical elongation treatment, the wear resistance is effectively increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com