Method for producing textile cloth and packaging material containing micro-capsule phase change material

A technology for phase change materials and packaging materials, applied in the application field of microcapsule phase change materials, can solve the problems of high cost and complicated application process of microcapsules, and achieve the effects of improving product quality, good endothermic performance and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

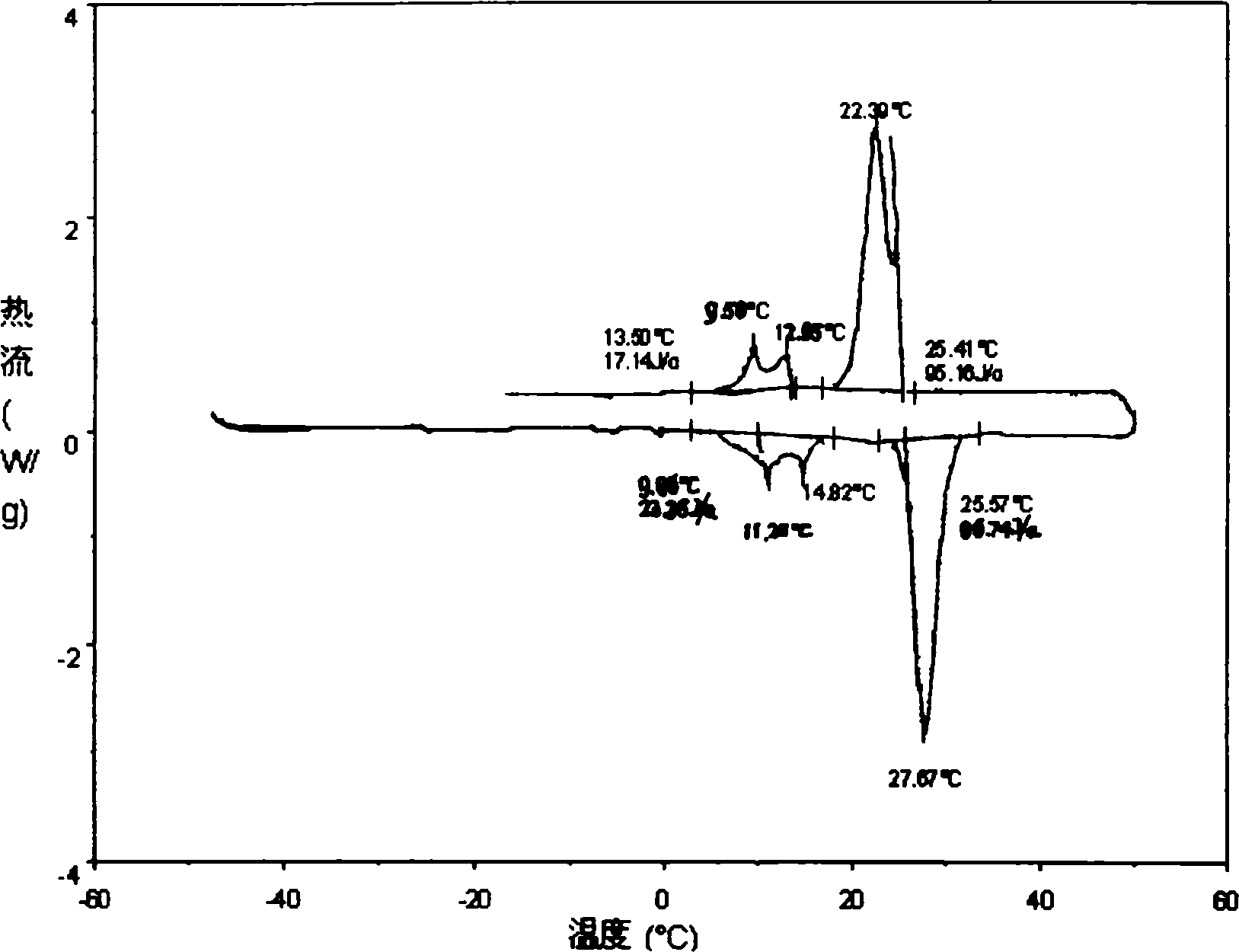

[0021] figure 1 It is a DSC curve diagram of a microcapsule phase change material with a phase transition temperature of 27°C, and its DSC curve is measured by an American MDSC 2910, TA Instruments type DSC tester. Such as figure 1 As shown, the peak endothermic temperature of the microcapsule phase change material is 27.67°C, and the total endothermic value is 96.74J / g, indicating that the material is a microcapsule phase change material with a phase change temperature of 27°C at room temperature. The capsule phase change material is a commercially available product, which is selected according to the phase change temperature. The particle size is selected as 2-7μm, and the endothermic and exothermic properties are as follows: figure 1 The shown aqueous solution containing 35% microcapsule phase change material is mixed with polyurethane screen printing adhesive at a ratio of 1:4, the mixture is dried and solidified at 120°C for 60 minutes, and the microcapsule phase change...

Embodiment 2

[0023] At room temperature, mix the microcapsule phase change material powder with a phase change temperature of 31°C, a particle size of 2-7 μm, and an endothermic heat of 158.7 J / g with an epoxy resin screen printing adhesive at a ratio of 4:5, and the mixture is heated at 230 Dry and solidify at ℃ for 5 minutes, and apply the microcapsule phase change material to the cotton cloth by embellishing silk screen printing technology. 40%.

Embodiment 3

[0025] At room temperature, mix the aqueous emulsion containing 10% microcapsule phase change material with a phase change temperature of 0°C and a particle size of 2 to 7 μm with an acrylic resin screen printing adhesive at a ratio of 1:9, wherein the microcapsule phase change material solution contains 48% aqueous solution of microencapsulated phase change material powder. The mixture was dried and solidified at 30°C for 120 minutes, and the microcapsule phase change material was coated on the packaging plastic cloth by dotted silk screen printing technology, in which the shape surface pattern was a cross star with a length and width of 6 mm and a height of 1 mm, containing micro Capsule Phase Change Material 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com