Two-purpose boring bar and hole-protecting casing soil anchor bolt boring technology

A drilling rod and hole forming technology, which is used in the installation of bolts, earthwork drilling, infrastructure engineering, etc., can solve the problems of increasing construction cost and project cost, low efficiency, complicated procedures, etc., and achieves fast hole drilling speed. , the effect of reducing costs and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The soil anchor hole forming process in which the drill pipe doubles as the hole protection casing includes the following steps:

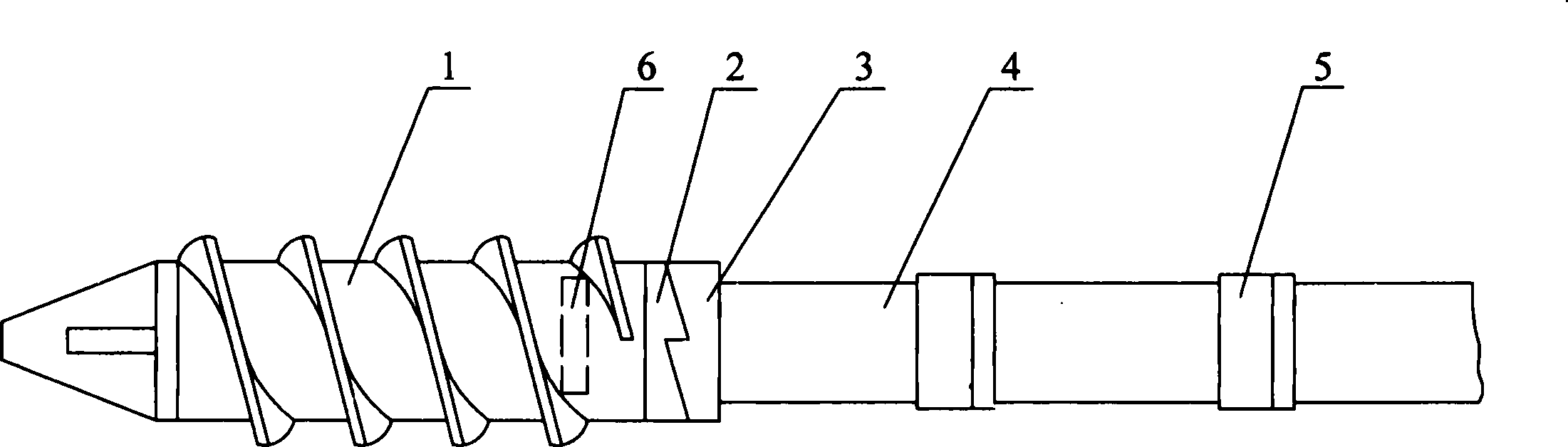

[0020] 1. To drill a hole, use a drilling tool with an auger bit (such as figure 1 As shown), the drilling tool with auger bit is composed of auger bit 1, female easy-reverse handle (or female plug-in handle) 2, male easy-reverse handle (or male plug-in handle) 3, drill pipe 4, drill pipe handle 5 and auger Drill bit 1 inner hole fixes locking sleeve 6 to form. The female easy-reverse handle 2 is fixedly connected to the rear end of the auger bit 1, and the male easy-reverse handle 3 is fixedly connected to the front end of the drill pipe; the male and female easy-reverse handles are screwed together, and the drill pipe 4 is composed of multiple inner flat drill pipes 4. A drill pipe receiver is connected in 5 phases.

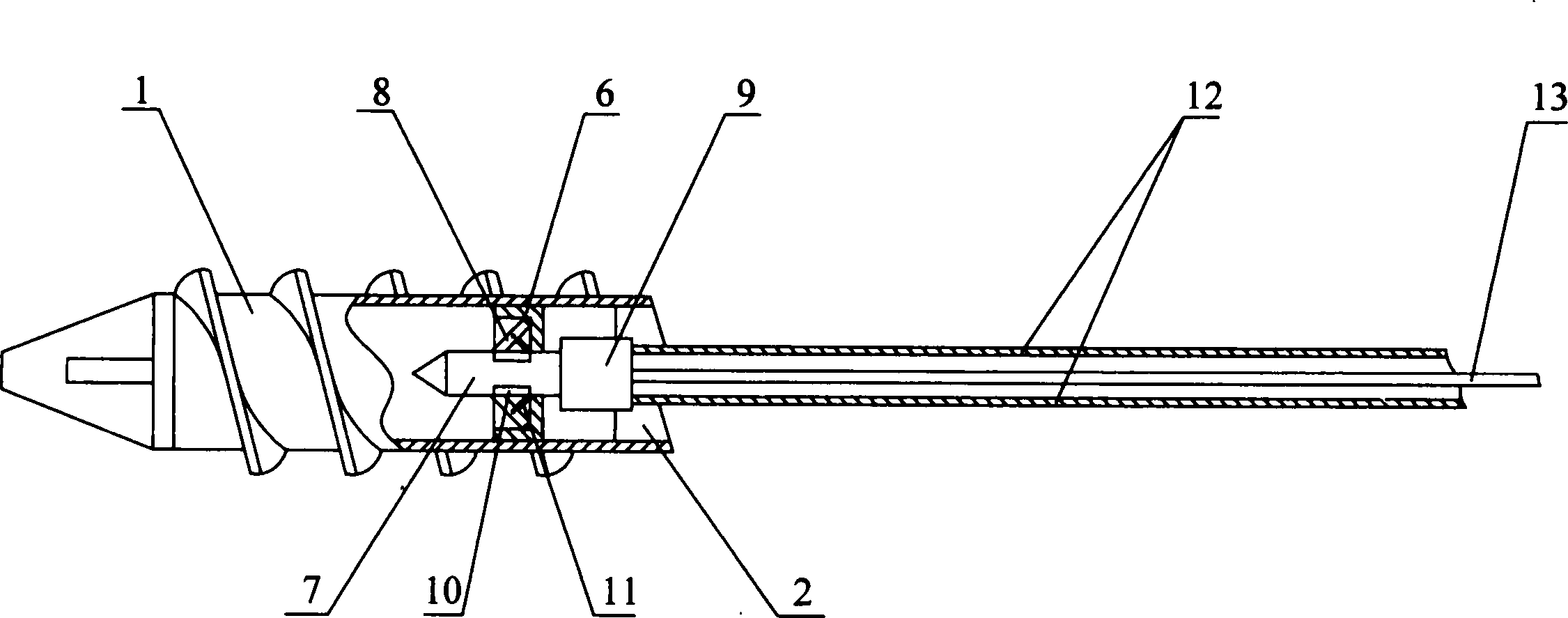

[0021] 2. When the drilling tool with the auger bit is drilled to the set position, the anchor rod (cable) with the docki...

Embodiment 2

[0024] The process steps adopted in embodiment two are basically the same as in embodiment one, except that the anchor rod (cable) 12 is a steel rod or steel strand, and a grouting pipe 13 is installed in the inner hole of the anchor rod (cable) 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com