Prying oil combustion supercritical pressure straight-flow steam boiler

A steam injection boiler and supercritical technology, which is used in steam boilers, water tube steam boilers, steam generation, etc., can solve the problems of supercritical pressure steam injection boilers that have not yet been produced, and can ensure supercritical parameters and prevent flue gas. Dead zone, the effect of saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

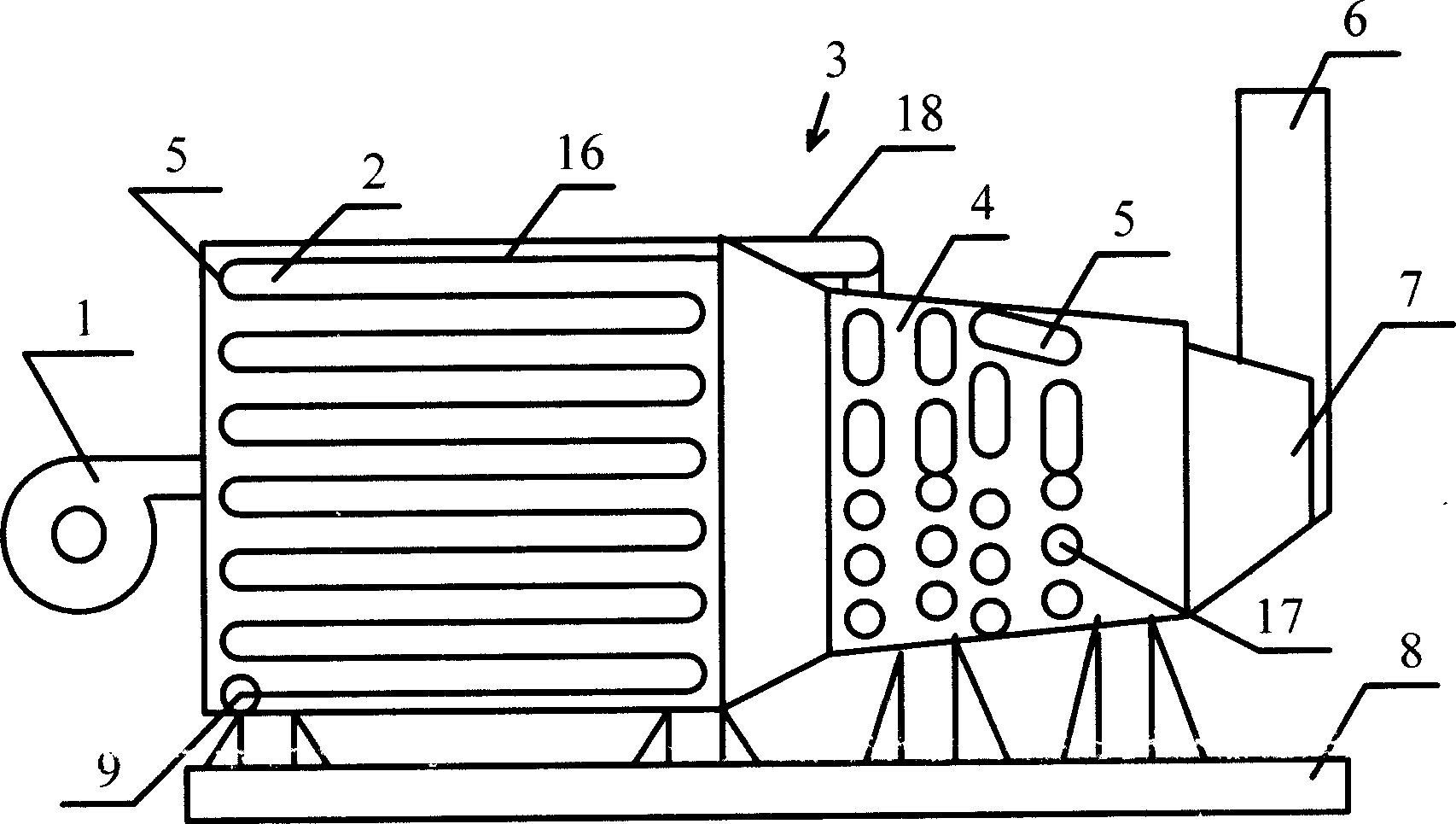

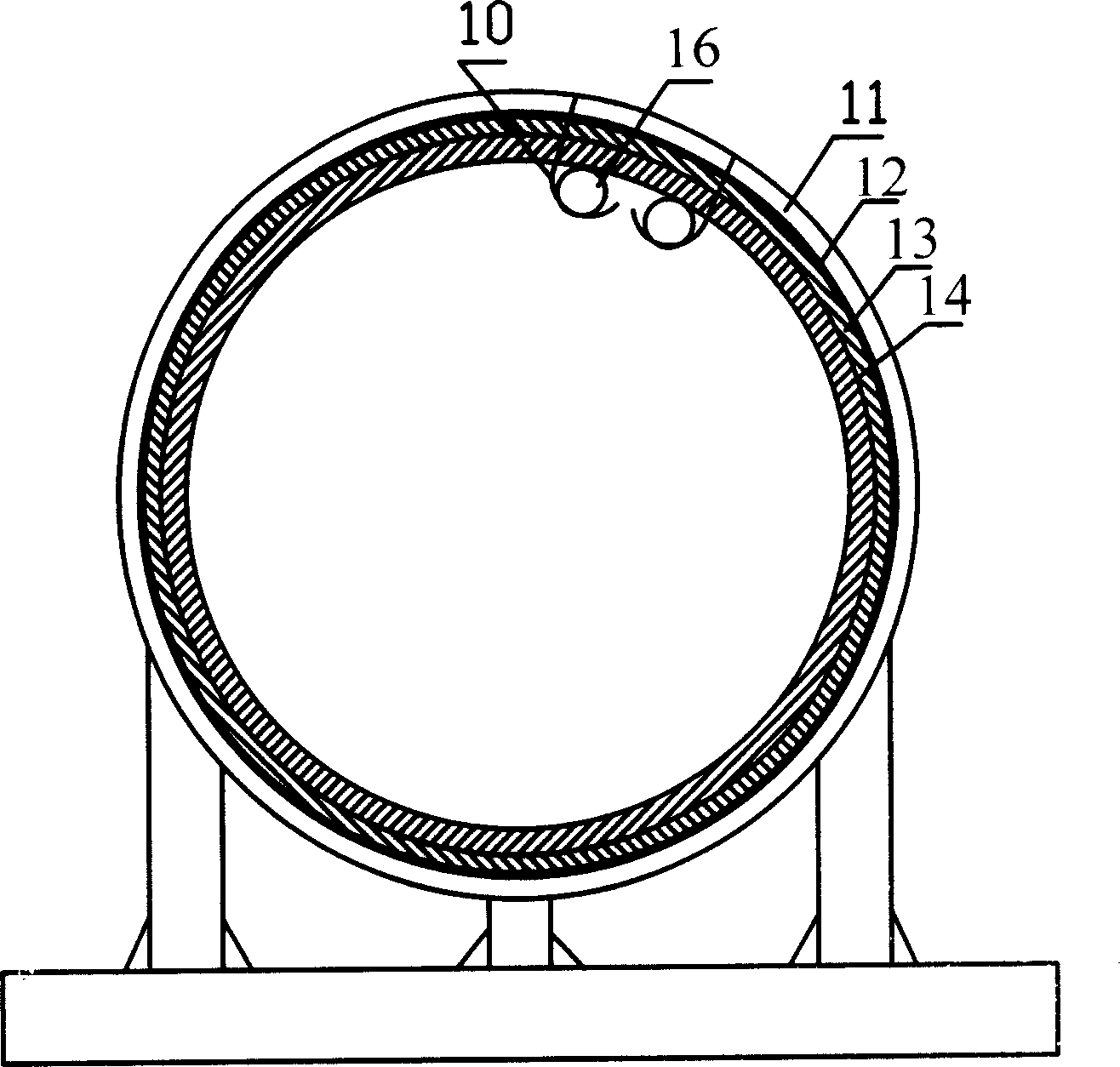

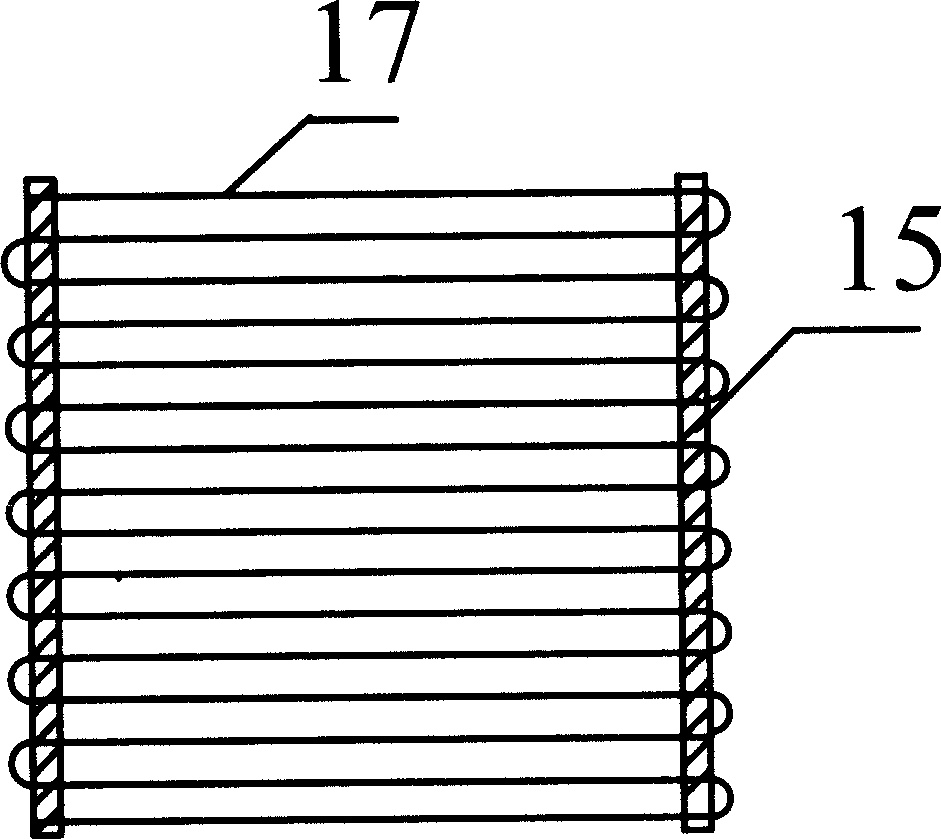

[0020] Such as figure 1 As shown, the boiler body 3 is installed on the boiler base 8 . The boiler body 3 mainly includes two heating surfaces: a radiation heating surface 2 and a convection heating surface 4 . The radiation heating surface is located in the furnace and is formed by coiling a single radiation heating tube 16 . The boiler body 3 is covered by a three-layer furnace wall. From the inside to the outside, there are corrugated plates 14 pressed by aluminum silicate refractory ceramic fibers, a heat insulating layer 13, and an infrared-proof coating layer 12. The burner 1 is installed on the front wall of the furnace wall, and is located on the center line of the cylindrical furnace. The convection heating surface 4 is a serpentine convection tube bundle formed by coiling a single convection heating tube 17 . At the tail of the convection heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com