Electrospark machining equipment

A processing equipment and EDM technology, which is applied in the field of EDM equipment, can solve the problems of large processing current, small processing aperture, automatic supply mechanism of filament electrodes, etc., so as to improve processing speed and processing accuracy, prevent longitudinal bending and Effects of vibration and reduction of machining preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, in order to explain the present invention in more detail, the best mode for carrying out the present invention will be described with reference to the accompanying drawings.

[0028] Implementation form 1.

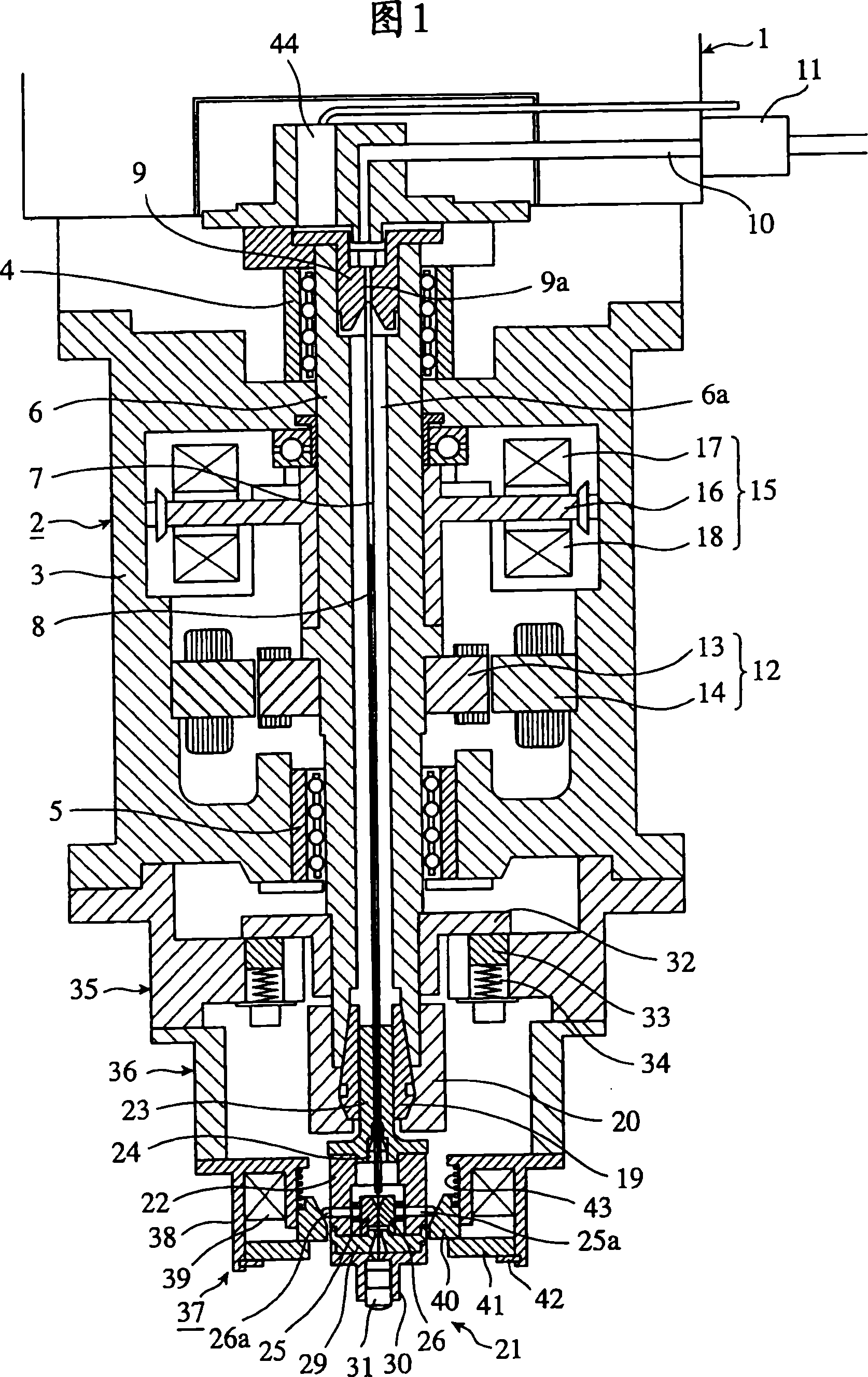

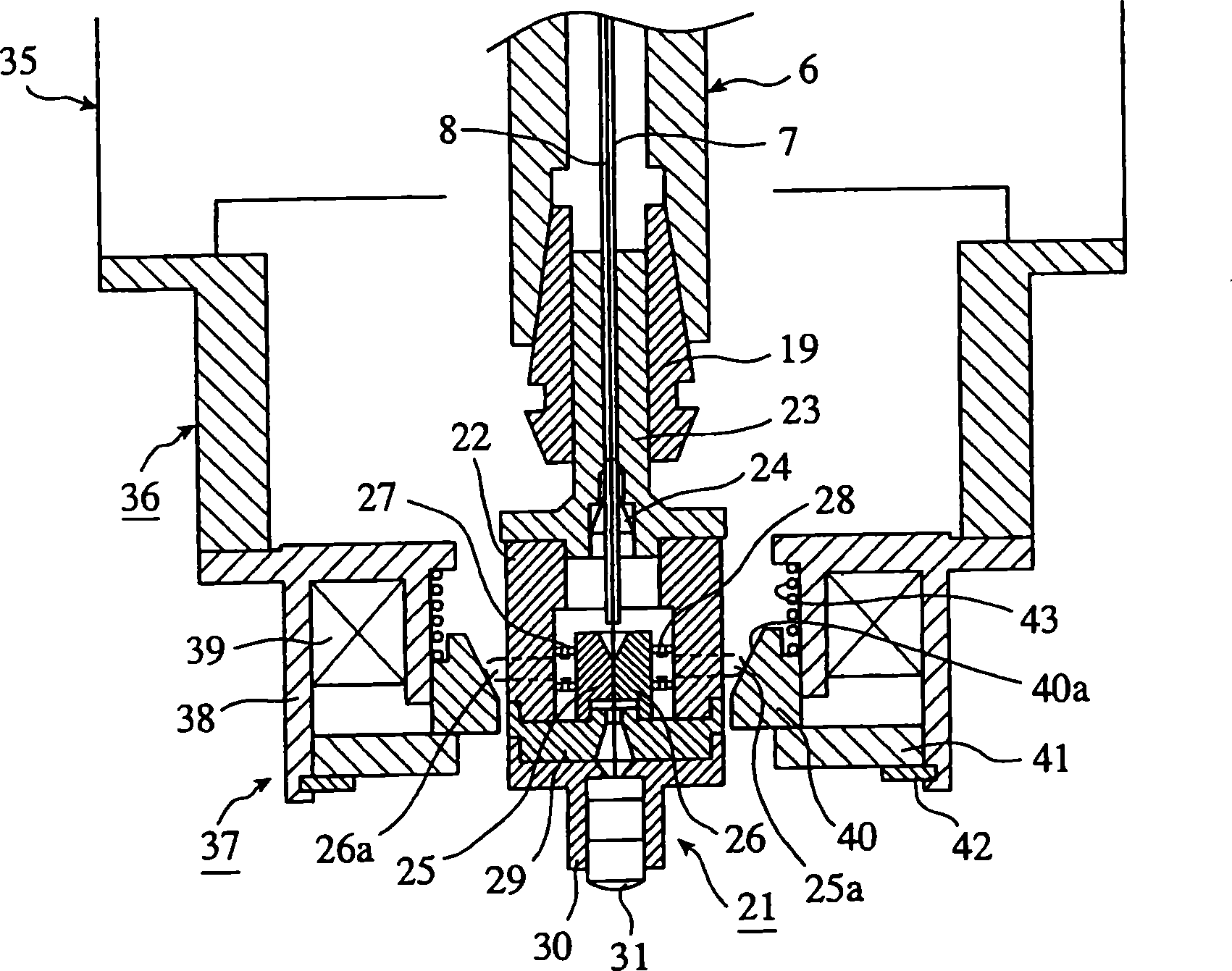

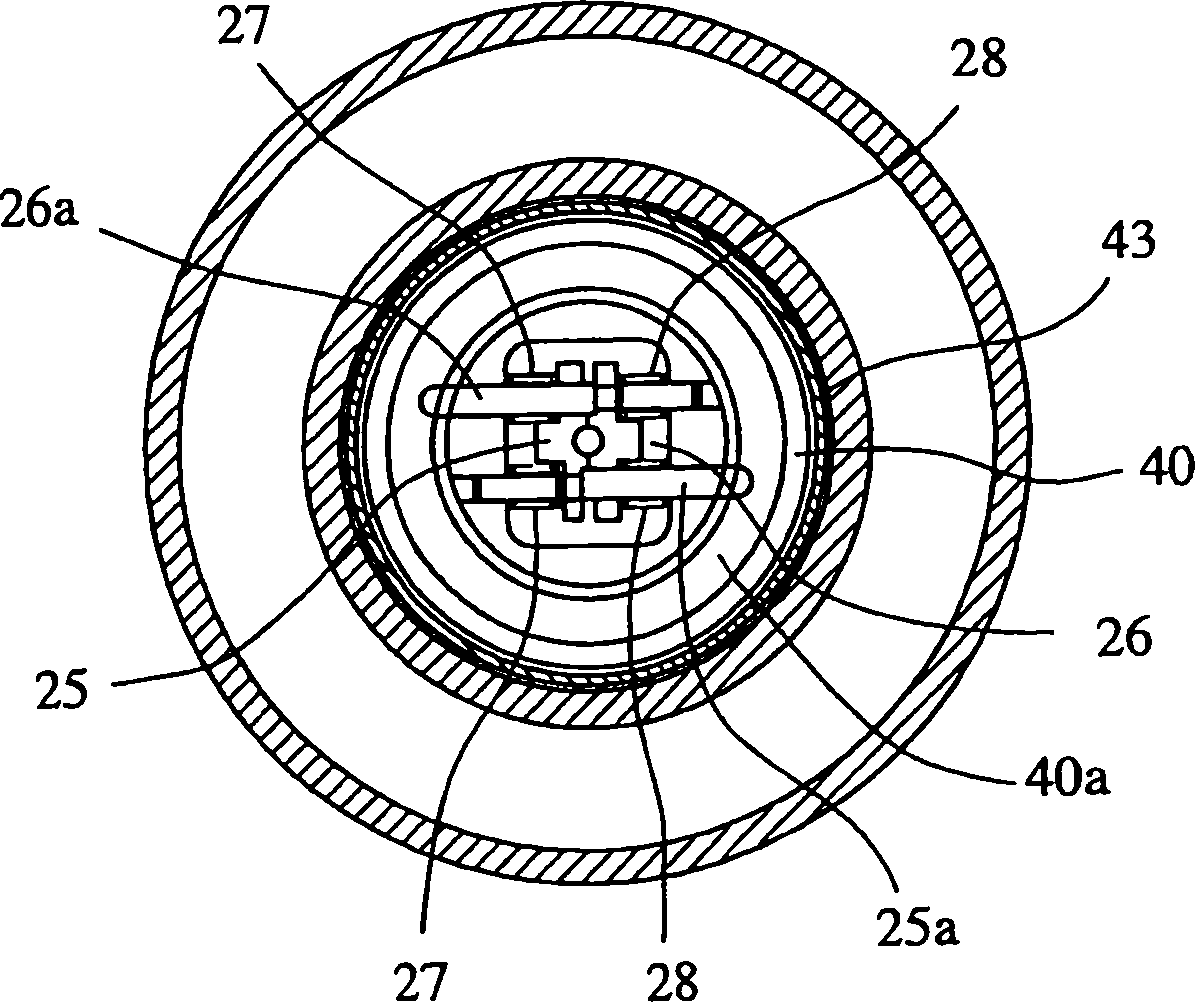

[0029] Fig. 1 shows the electrical discharge machining equipment according to Embodiment 1 of the present invention, figure 2 is an enlarged sectional view of the main part of Fig. 1, image 3 yes figure 2 A cross-sectional view of the main parts.

[0030]In FIG. 1 , a high-speed-response electrode drive device 2 is mounted on a spindle head 1 of an electric discharge machine. This electrode driving device 2 is provided with: a casing 3 which becomes the main body of the device; and a drive shaft 6 which is rotatably mounted on the casing 3 via upper and lower bearings 4, 5 and which can move in the axial direction. inner center. As the bearings 4 and 5, bearings that allow the drive shaft 6 to move in the axial direction (thrust direction), such as a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com