Hollow ball granular chain of nano-polycrystalline noble-metal and its production

A precious metal, particle chain technology, applied in the field of nanoparticles, can solve the problems of lack of order and difficult manipulation of hollow spherical nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Preparation of polycrystalline Au hollow sphere particle chains with an average size of 50 nanometers

[0028] First configure the precursor colloid solution A for preparing noble metal hollow ball chains. The steps are: under an inert atmosphere—nitrogen gas is used in this example, 200mg of PVP is ultrasonically dissolved in 20ml of water, and then 11.9mg of CoCl is weighed 2 ·6H 2 O dissolves into this solution. This solution is transferred in the three-neck flask of 100ml capacity, inserts the stirring piece of mechanical stirrer from the bottle mouth in the middle, nitrogen is led into from the next bottle mouth, and a dropping funnel is put on the other bottle mouth. The entire reaction system was placed in a uniform magnetic field of 200 mTesla. Hold for 15 minutes at a mechanical stirring speed of 1000 rpm. Another 5mg NaBH 4 Dissolve in 10ml of water and transfer quickly to the dropping funnel. Then within 1 minute this NaBH 4 The aqueous solut...

Embodiment 2

[0033] Example 2: Preparation of polycrystalline Pd hollow sphere particle chains with an average size of 50 nanometers

[0034] Configure palladium source solution D: weigh 88.66mg PdCl 2 , was dissolved in 10 ml of 1M HCl, neutralized to pH=7.0 with 1M KOH solution, and then diluted to 20 ml.

[0035]Using the same operation and method as in Example 1, the configured palladium source solution D was added dropwise to the colloidal precursor A used for the preparation of hollow ball chains, and mechanical stirring was continued for 30 minutes under an inert atmosphere to obtain a black colloidal solution . The purification steps are the same as in Example 1, and finally dissolved in 1 ml of absolute ethanol to form a black colloidal solution.

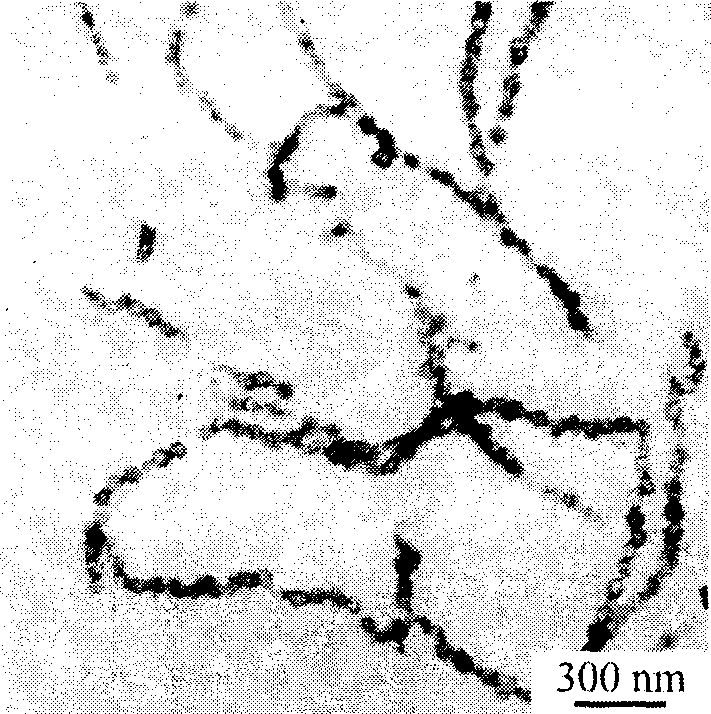

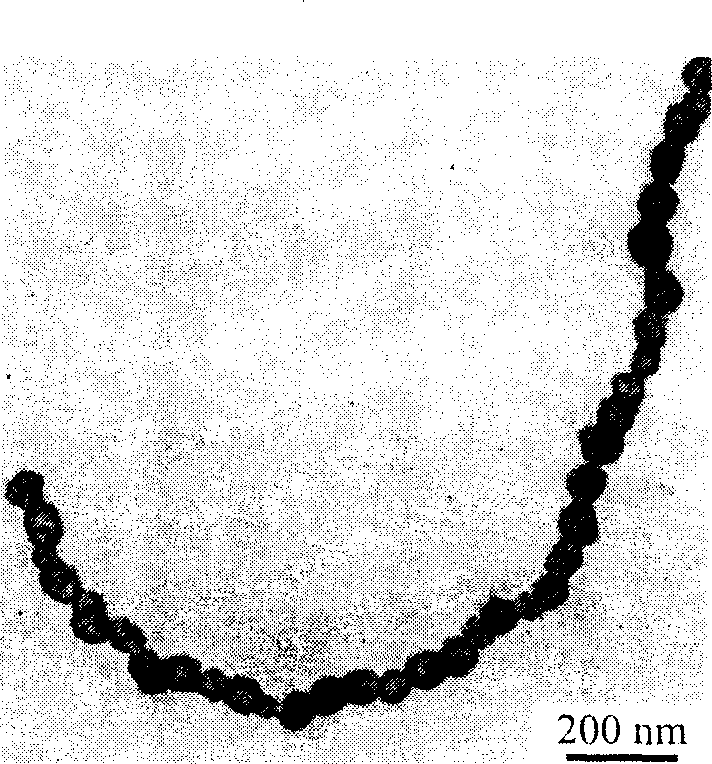

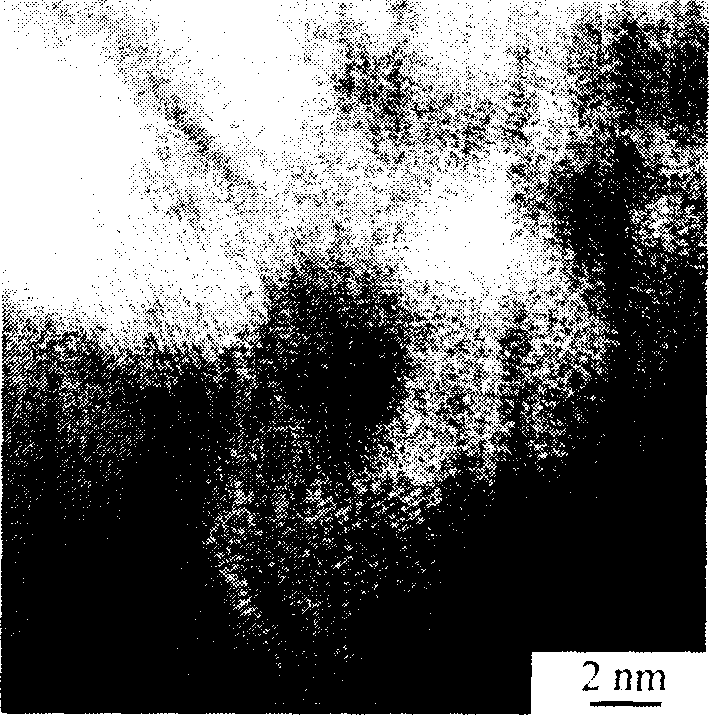

[0036] Sample testing and data processing methods are the same as in Example 1. Image 6 It is a transmission electron microscope photo of a single Pd hollow ball chain. From the photo, it can be seen that the Pd hollow ball particle...

Embodiment 3

[0037] Example 3: Preparation of polycrystalline Pt hollow sphere particle chains with an average size of 40 nanometers

[0038] Configure platinum source solution E: weigh 0.24g H 2 PtCl 6 ·6H 2 O was dissolved in 10ml of water, and 1M KOH solution was added dropwise to neutralize to pH=7.0, and then diluted to 20ml.

[0039] Using the same operation and method as in Example 1, the configured platinum source solution E was added dropwise to the colloidal precursor solution A used for the preparation of hollow ball chains, and mechanical stirring was continued for 30 minutes under an inert atmosphere to obtain a black colloidal solution . The purification method is the same as in Example 1, and finally dissolved in 1 ml of absolute ethanol to form a black colloidal solution.

[0040] Sample testing and data processing methods are the same as in Example 1. Figure 10 It is a transmission electron microscope photo of a single Pd hollow sphere chain. It can be seen from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com