A kind of preparation method of homogeneous membrane

A technology of porous membrane and solution, applied in the field of preparation of phenolic resin homoporous membrane, can solve the problems of incomplete removal of template agent, need special equipment, limited application scope, etc. good order effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 0.10g of sodium hydroxide aqueous solution to 0.47g of molten phenol and stir evenly, add 0.81g of formaldehyde solution and react the solution at 60°C for 2h, adjust the solution to be neutral with hydrochloric acid solution; after drying, the phenolic resin prepolymer will be obtained Dissolve 1.26g of block copolymer F127 in 10.0g of water to obtain a solution; transfer the solution to a petri dish, and after the solvent is completely evaporated, heat and cure for 1 hour to obtain a composite film of phenolic resin and block copolymer; The composite membrane was placed in a 1,2-dichloroethane solution with a molar concentration of 0.5% of 1,4-p-dichlorobenzyl and a molar concentration of anhydrous ferric chloride of 1.0%, and was heated to 40°C for 24 hours.

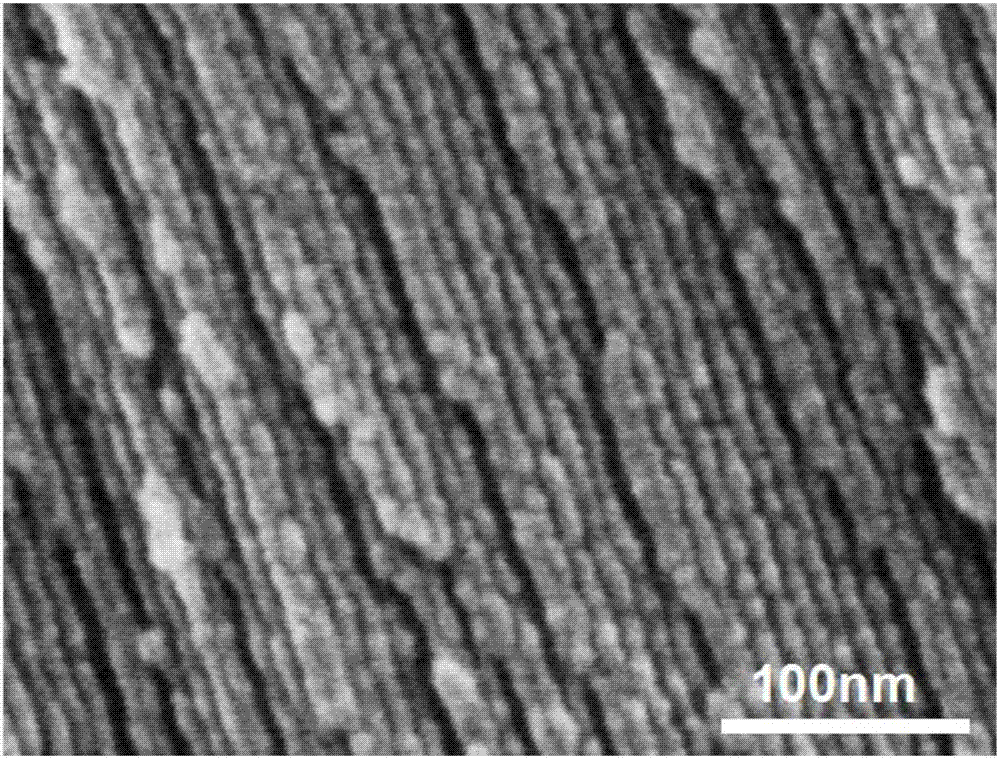

[0039] figure 1 It is the SEM picture of the phenolic resin homoporous membrane prepared in this example. It can be seen from the figure that the membrane prepared in this example has an ordered two-dimens...

Embodiment 2

[0047]Add 0.10g of sodium hydroxide aqueous solution into 0.47g of molten phenol and stir evenly, add 0.81g of formaldehyde solution and react the solution at 70°C for 1.25h, adjust the solution to be neutral with hydrochloric acid solution; after drying, the prepolymerized phenolic resin will be obtained The body and 0.58g block copolymer P123 were dissolved in 10.0g methanol to obtain a solution; the solution was transferred to a petri dish, and after the solvent was completely volatilized, it was heated and solidified for 12 hours to obtain a composite film of phenolic resin and block copolymer; The obtained composite membrane was placed in a dimethylformamide solution with a molar concentration of 1,4-dibromobutane of 1.5% and anhydrous aluminum chloride of 5.0%, and was heated to 60°C for 12 hours.

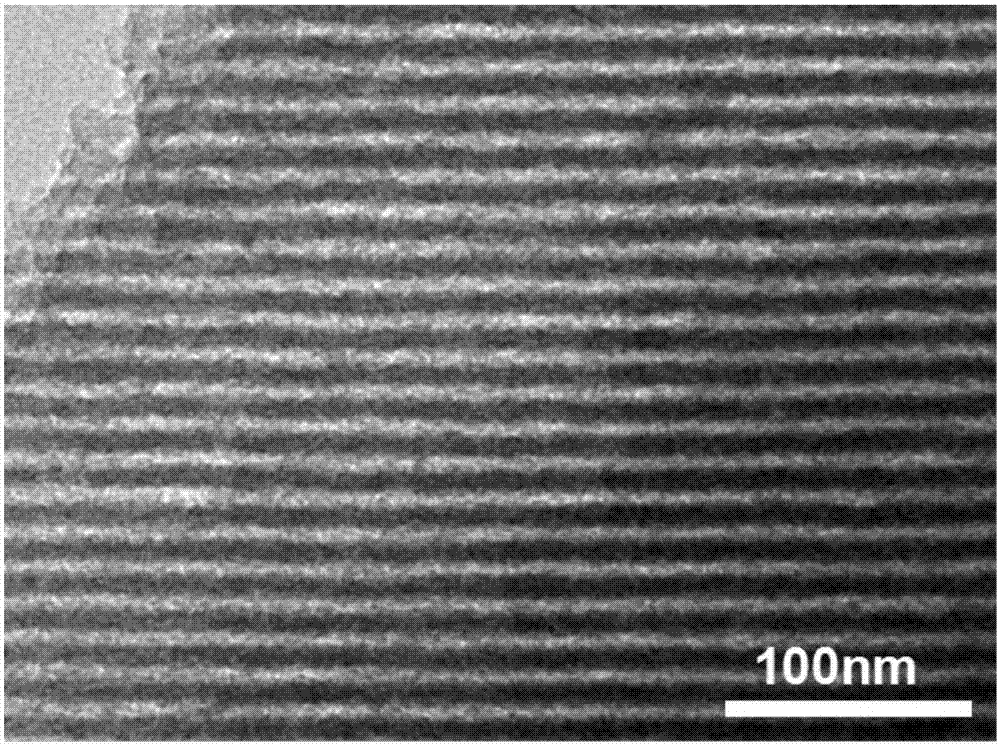

[0048] Figure 7 It is the SEM image of the phenolic resin homoporous membrane prepared in this example. It can be seen from the figure that the homoporous membrane prepared...

Embodiment 3

[0055] Add 0.10g of sodium hydroxide aqueous solution into 0.47g of molten phenol and stir evenly, add 0.81g of formaldehyde solution and react the solution at 90°C for 2 hours, adjust the solution to be neutral with hydrochloric acid solution; after drying, the phenolic resin prepolymer will be obtained Dissolve 1.10 g of block copolymer F108 in 10.0 g of ethanol to obtain a solution; transfer the solution to a petri dish, and after the solvent is completely volatilized, heat and cure for 24 hours to obtain a composite film of phenolic resin and block copolymer; The obtained composite membrane was placed in a dimethyl sulfoxide solution with a molar concentration of 1,4-terephthaloyl chloride of 2.5% and anhydrous tin tetrachloride of a molar concentration of 3.0%, and was heated to 80°C for 5 hours.

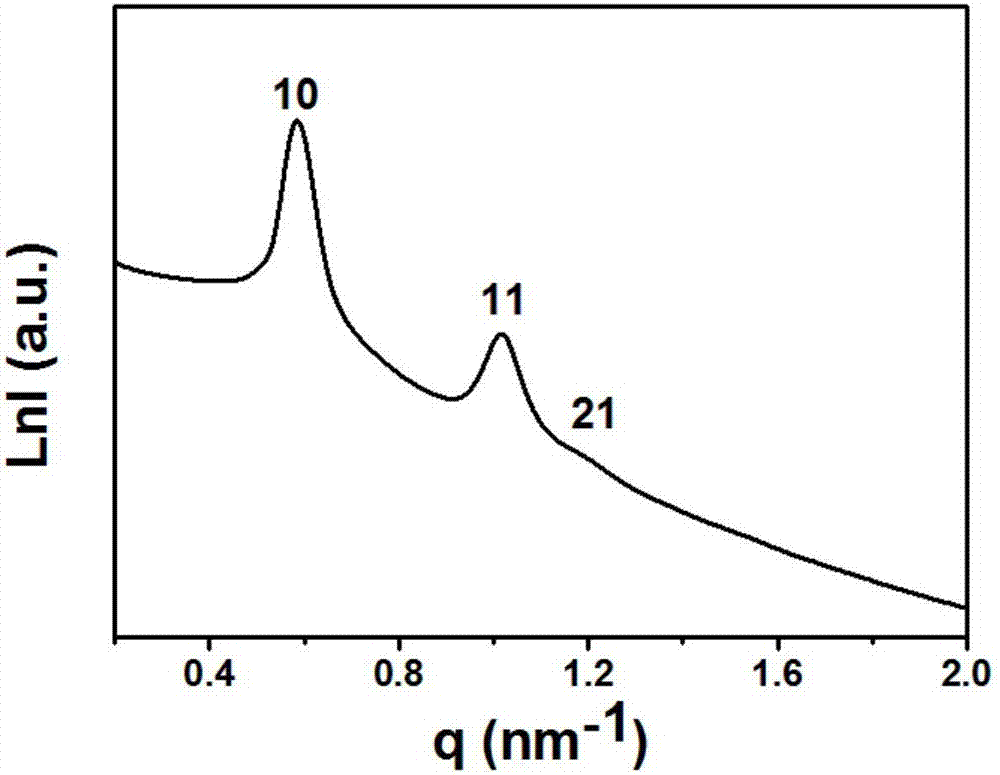

[0056] SEM figure, TEM figure, SAXS spectrogram, N 2 The analysis results of the adsorption-desorption isotherm diagram, pore size distribution curve diagram and FT-IR diagram ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com