Vortex compressor and its vacuum preventer

A scroll compressor and vacuum technology, applied in the direction of rotary piston machinery, rotary piston pumps, components of pumping devices for elastic fluids, etc., can solve the problem of reducing compressor compression efficiency, inconvenience, and lubricating oil residue and other issues to achieve the effect of improving production efficiency, reducing costs, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and structure of the vacuum prevention device for scroll compressors proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail below.

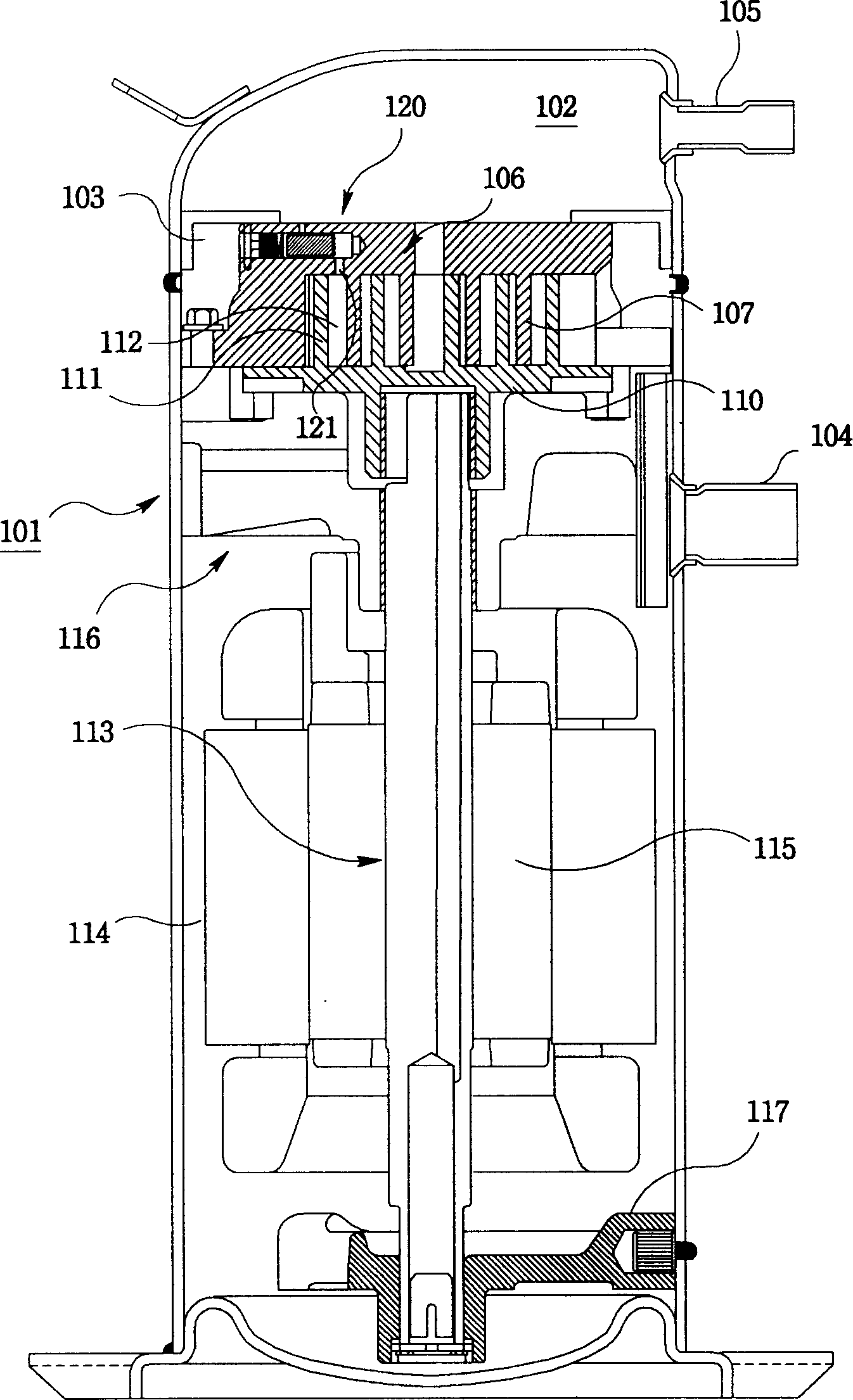

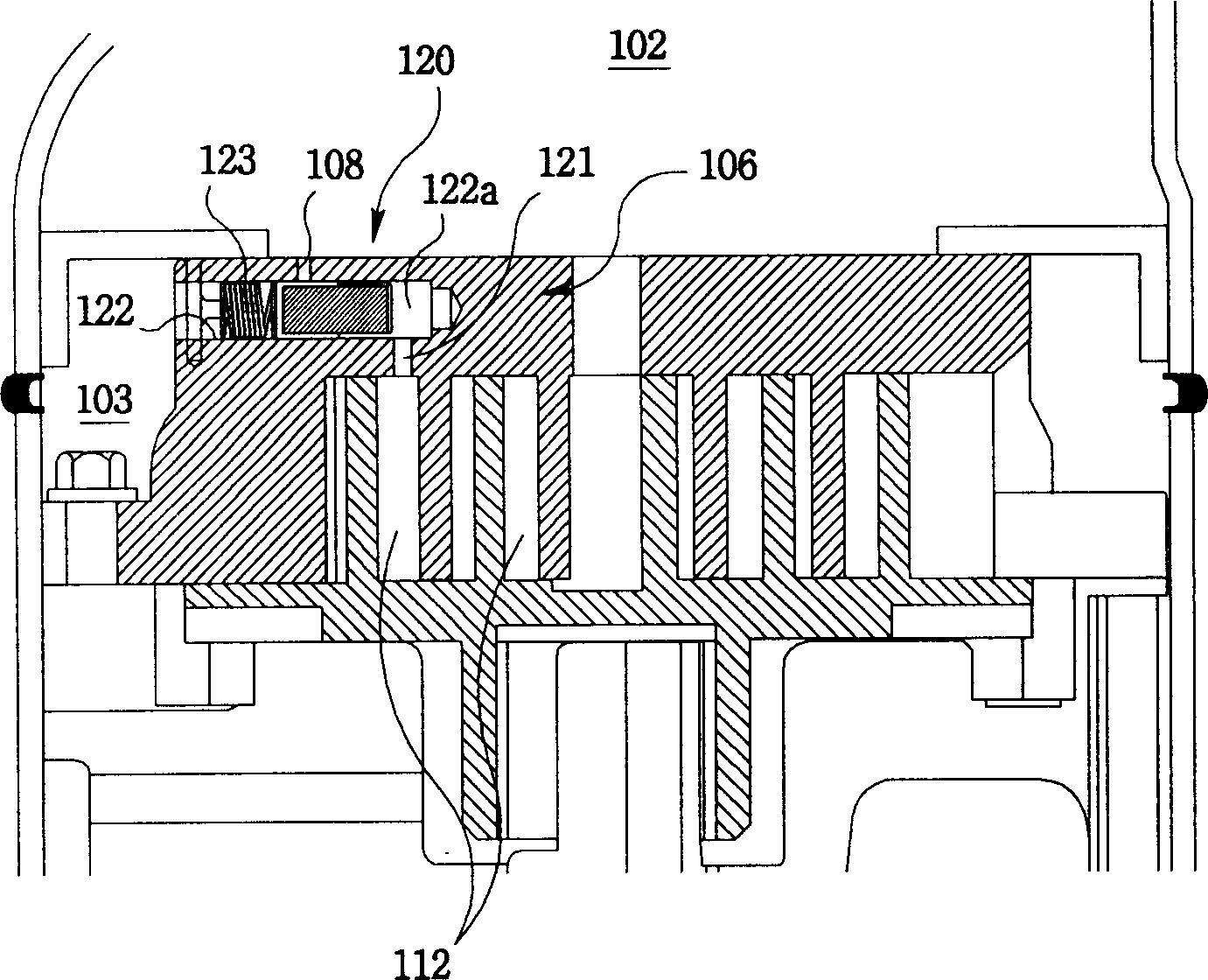

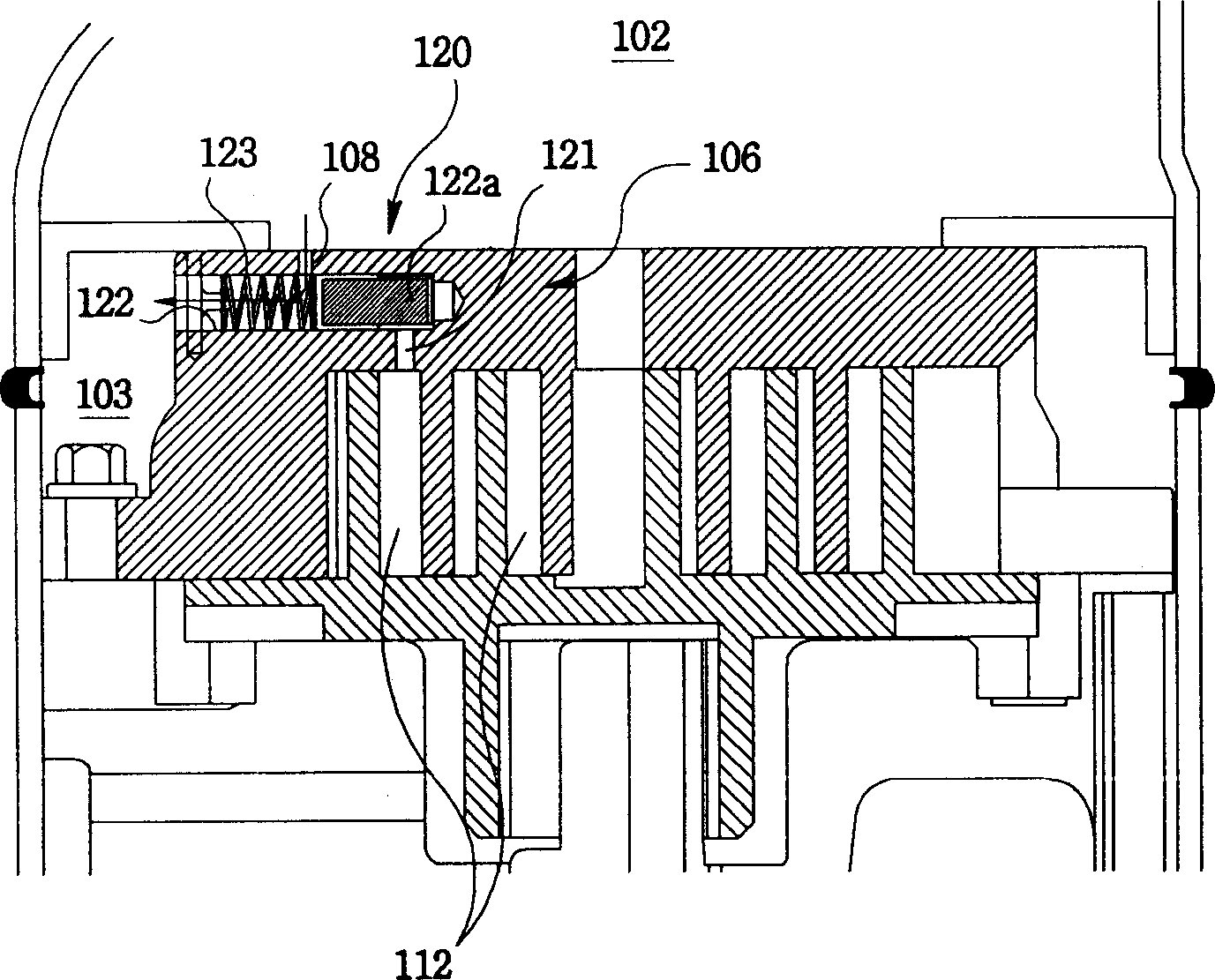

[0061] see Figure 4 Shown is a longitudinal sectional view of a scroll compressor using the first embodiment of the vacuum preventing device of the present invention. The scroll compressor of the present invention includes: a cylindrical casing 1 divided into a low-pressure chamber 2 having a suction pipe 3 for sucking in refrigerant from the outside and a high-pressure chamber 4 having a discharge pipe 5 for discharging high-pressure refrigerant; Equipped with an involute-shaped compression chamber 23, the low-pressure refrigerant in the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com