Permanent magnetism synchrounous electromotor control device

A permanent magnet synchronous control device technology, applied in the direction of motor generator control, AC motor control, electronic commutation motor control, etc., can solve the problems of torque characteristic deterioration, permanent magnet synchronous motor influence, and no record of synchronous operation load fluctuation Countermeasures and other problems to achieve the effect of suppressing speed fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

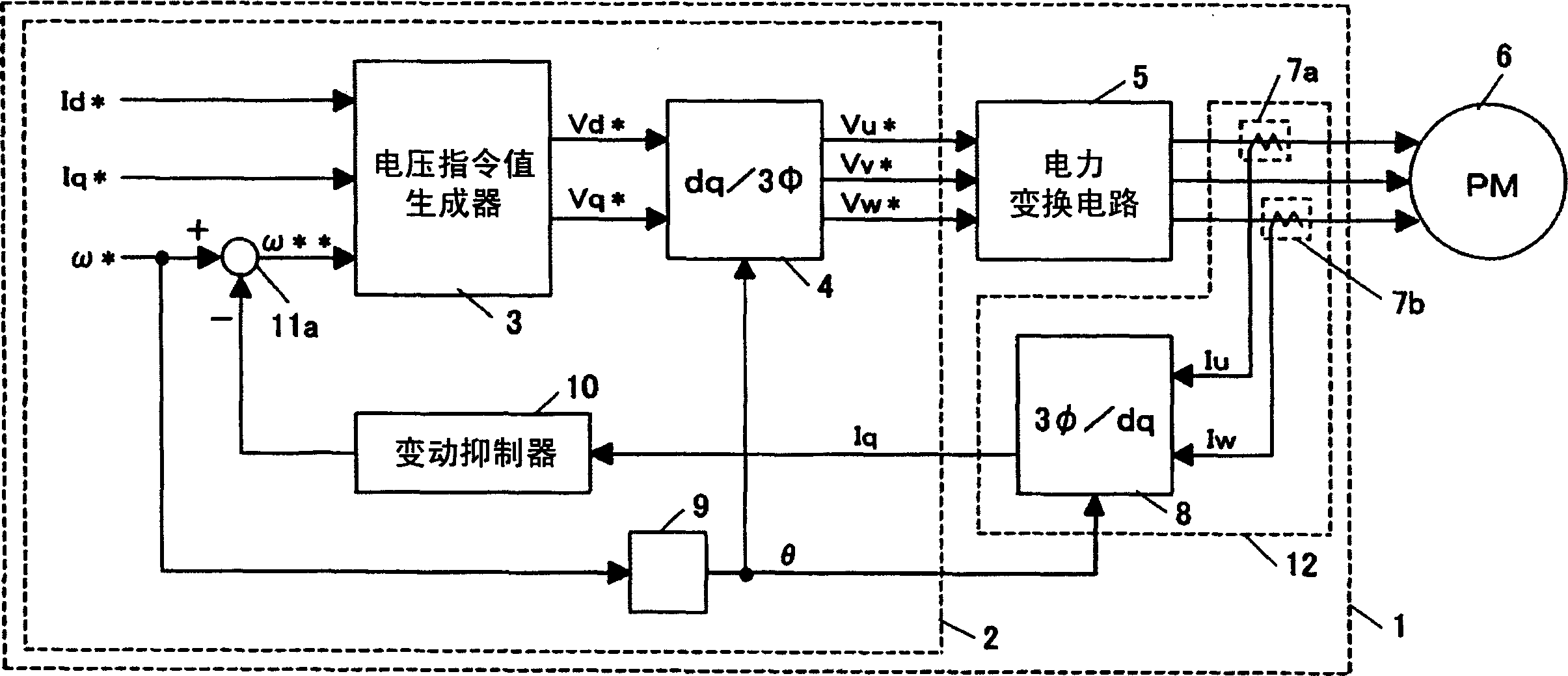

[0035] Embodiment 1 of the related permanent magnet synchronous motor of the present invention will be described.

[0036] First compare figure 1 , the current detection means 12 for obtaining the q-axis current flowing in the permanent magnet synchronous motor will be described.

[0037] The current detection means 12 is composed of a detection means for detecting the three-phase alternating current, and a means for converting the three-phase axes into dq axes and obtaining the d-axis and q-axis currents. As detection means for detecting 3-phase alternating current, current detecting circuits (7a and 7b) are used in the present invention to detect U-phase and W-phase in the 3-phase alternating current flowing through the permanent magnet synchronous motor.

[0038] Since the permanent magnet synchronous motor 6 is Y-connected, it is only necessary to detect two or more phases of the alternating current flowing through the permanent magnet synchronous motor. In addition, any...

Embodiment 2

[0068] control Figure 5 ~ Figure 8 Embodiment 2 of the related permanent magnet synchronous motor of the present invention will be described.

[0069] The current detection mechanism 12a that detects the d-axis and q-axis currents flowing in the permanent magnet synchronous motor, and inputs the current detected by the current detection mechanism 12a and outputs the 3-phase voltage command value that is finally applied to the permanent magnet synchronous motor 6 (Vu * 、Vv * 、Vw * ) is different from Embodiment 1 in the configuration of the control unit 2a. In this embodiment, using the detection values of the d-axis and q-axis currents, the three-phase voltage command values (Vu * 、Vv * 、Vw * ).

[0070] First, the current detection mechanism 12a that detects the d-axis and q-axis currents flowing through the motor will be described.

[0071] Such as Figure 6 As shown, the current detection mechanism 12a is composed of the current detection circuit 7c and the cu...

Embodiment 3

[0102] control Figure 9 Embodiment 3 of the control device for the related permanent magnet synchronous motor of the present invention will be described.

[0103] Figure 9 It is a schematic diagram illustrating the washing machine 200 when the control device 201 for the permanent magnet synchronous motor of the present invention is applied to the drive system of the washing machine.

[0104] The washing machine 200 is provided with a washing tank 206 and an agitating blade (vibrator) 205 in a water tank 208 , and the washing tank 206 and the agitating blade 205 are driven by a motor 203 . Which one of the washing tub 206 and the stirring blade 205 is driven is switched by the clutch unit 204 in the washing step.

[0105] In addition, the clutch unit 204 may also be provided with a reduction mechanism. The control device 201 of the permanent magnet synchronous motor applies an AC voltage to the permanent magnet synchronous motor 203 through the wiring 202 for driving.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com