Support structure for a load-bearing device

一种支承结构、连接机构的技术,应用在测量装置、仪器、科学仪器等方向,能够解决降低、不能缓冲振动吸收能量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

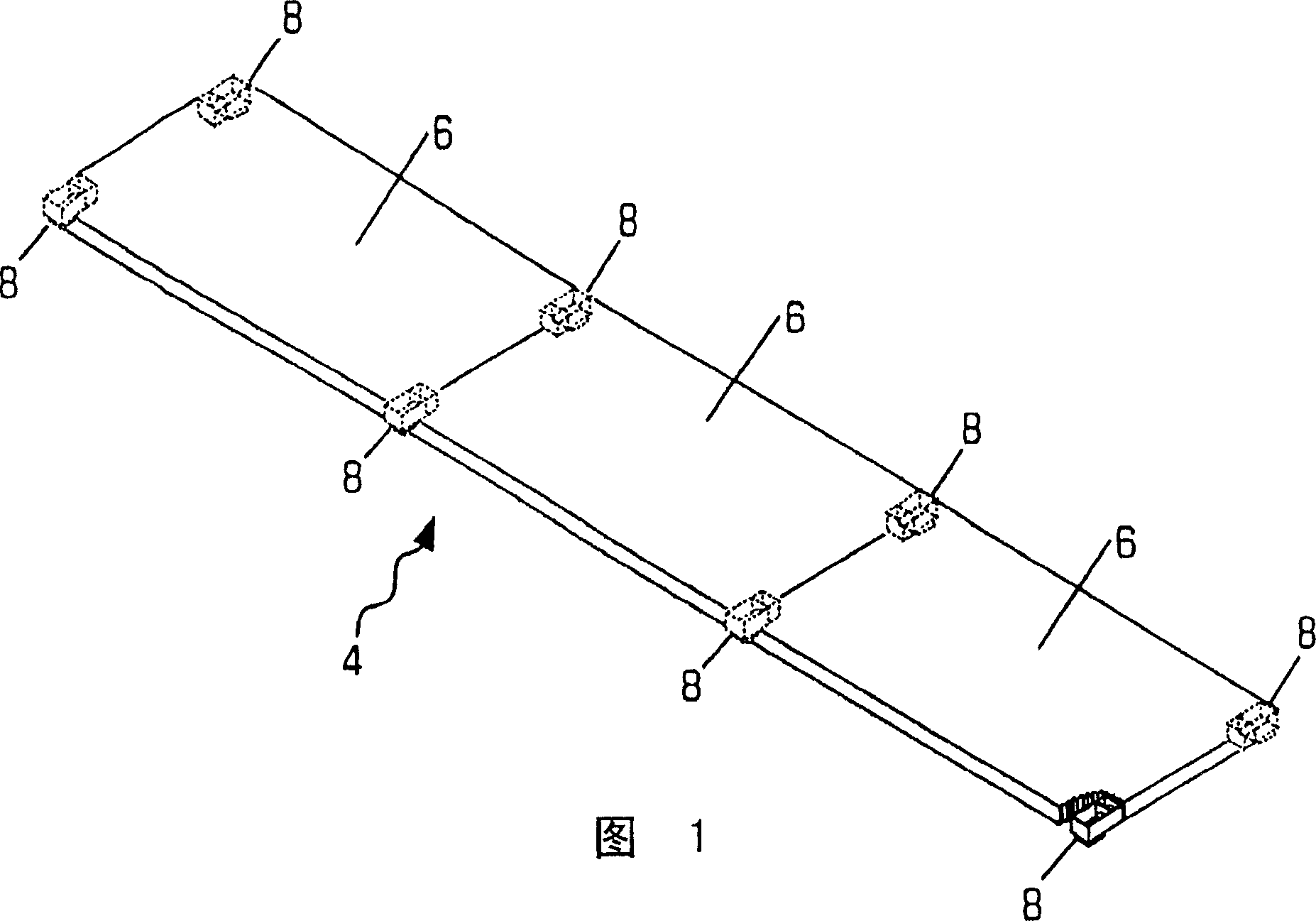

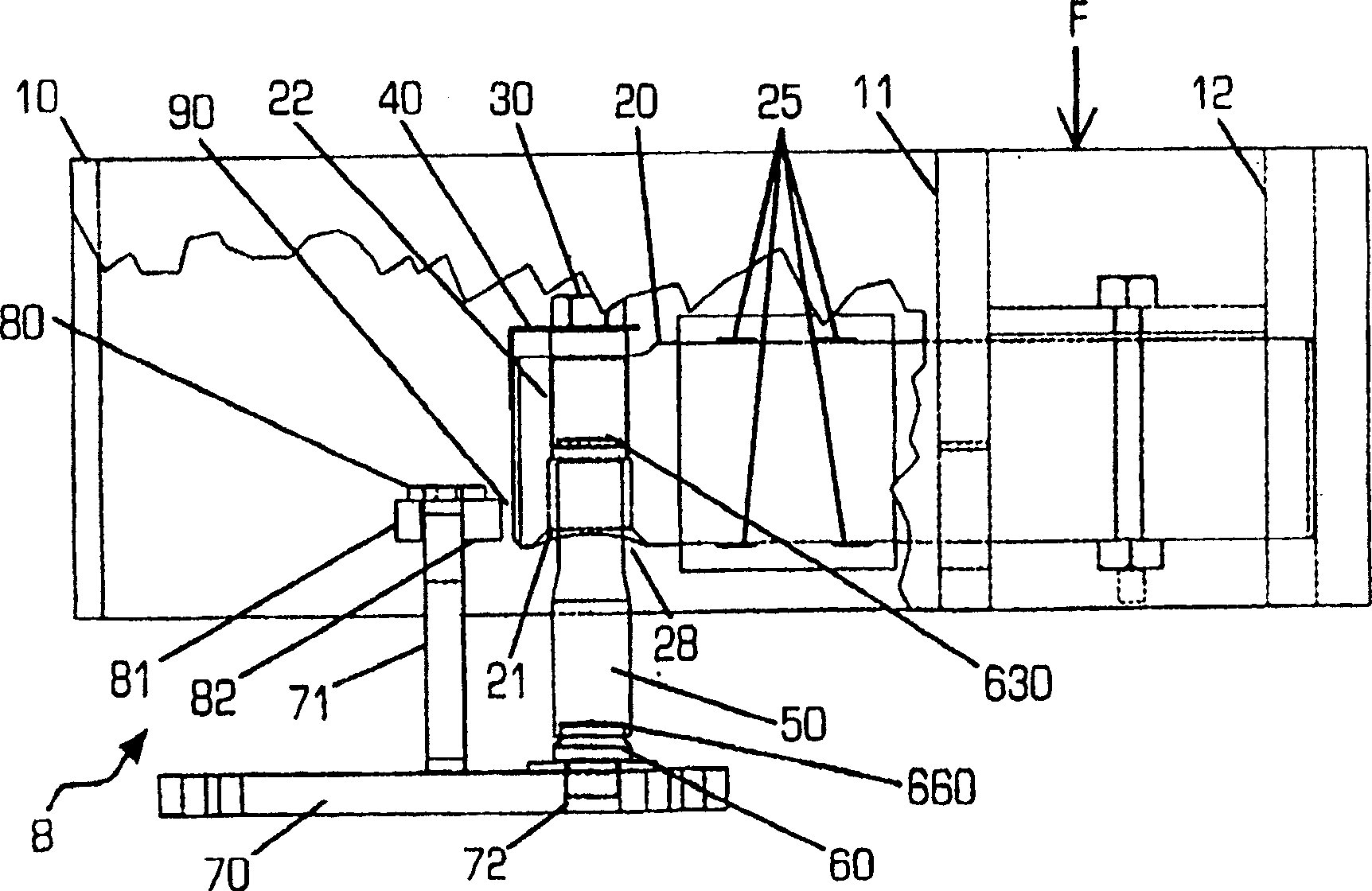

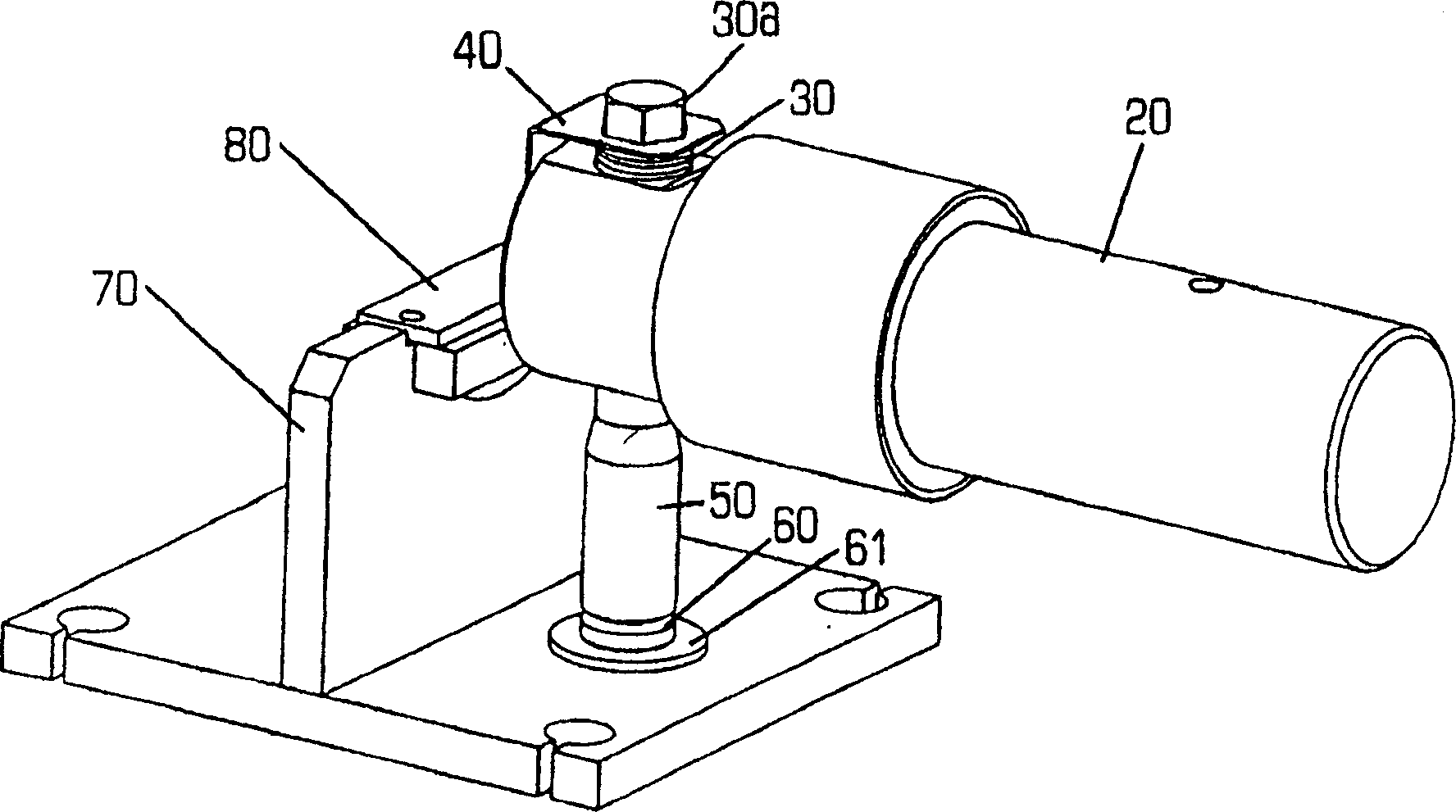

[0030] Embodiments of the invention are described herein in the description of load cells, and in particular in the description of multi-load cell scales. However, it should be understood that the embodiments provided herein are preferred embodiments only, and the scope of the present invention is not limited to the applications or embodiments disclosed herein. For example, the support structure may be used in any application where it is desired to reduce the combined forces acting in directions other than the direction of interest. Also, while a cylindrical embodiment of the support structure is disclosed, the support structure may have any shape suitable for a particular application. While oblate spheroidal surfaces are disclosed, those of ordinary skill in the art will appreciate that any suitable surface of revolution having non-uniform curvature, such as parabolic, hyperbolic, sinusoidal, and exponential surfaces, may be employed with the present invention, depending on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com