Realtime monitor device for granular articles

A technology for real-time monitoring and particulate matter, which is applied to the analysis of materials and instruments, can solve problems such as large air resistance, waste, and increased resistance, and achieve the effects of improved accuracy, shortened time, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

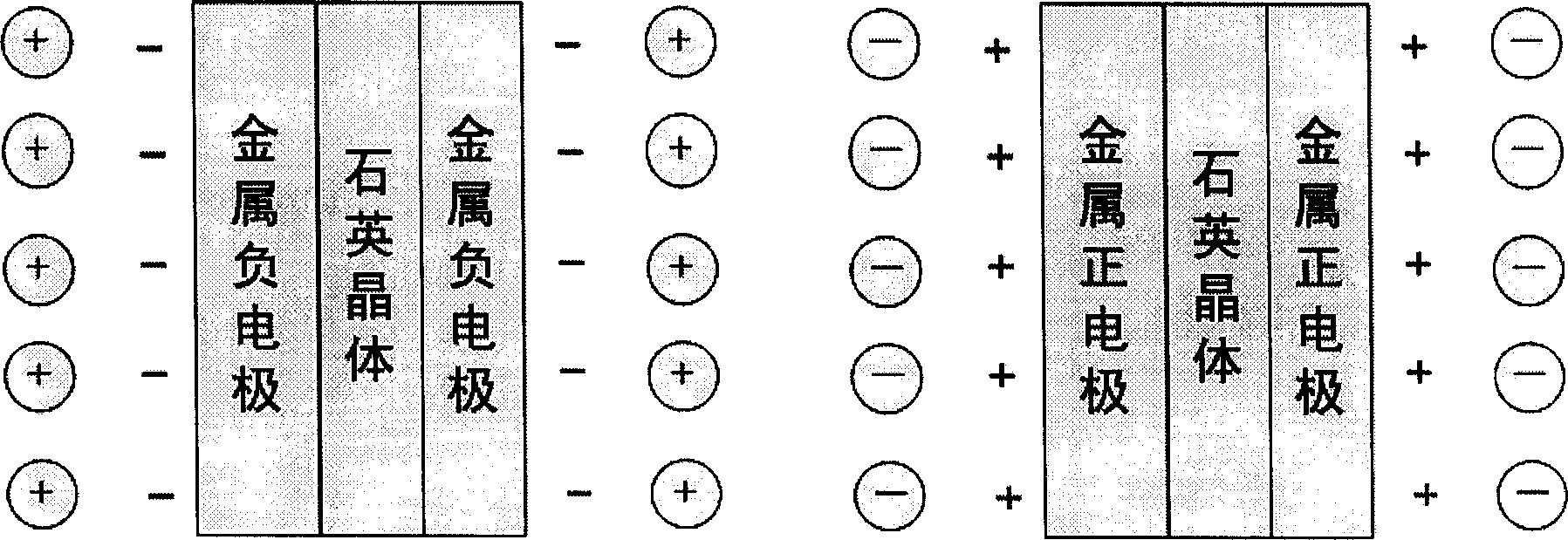

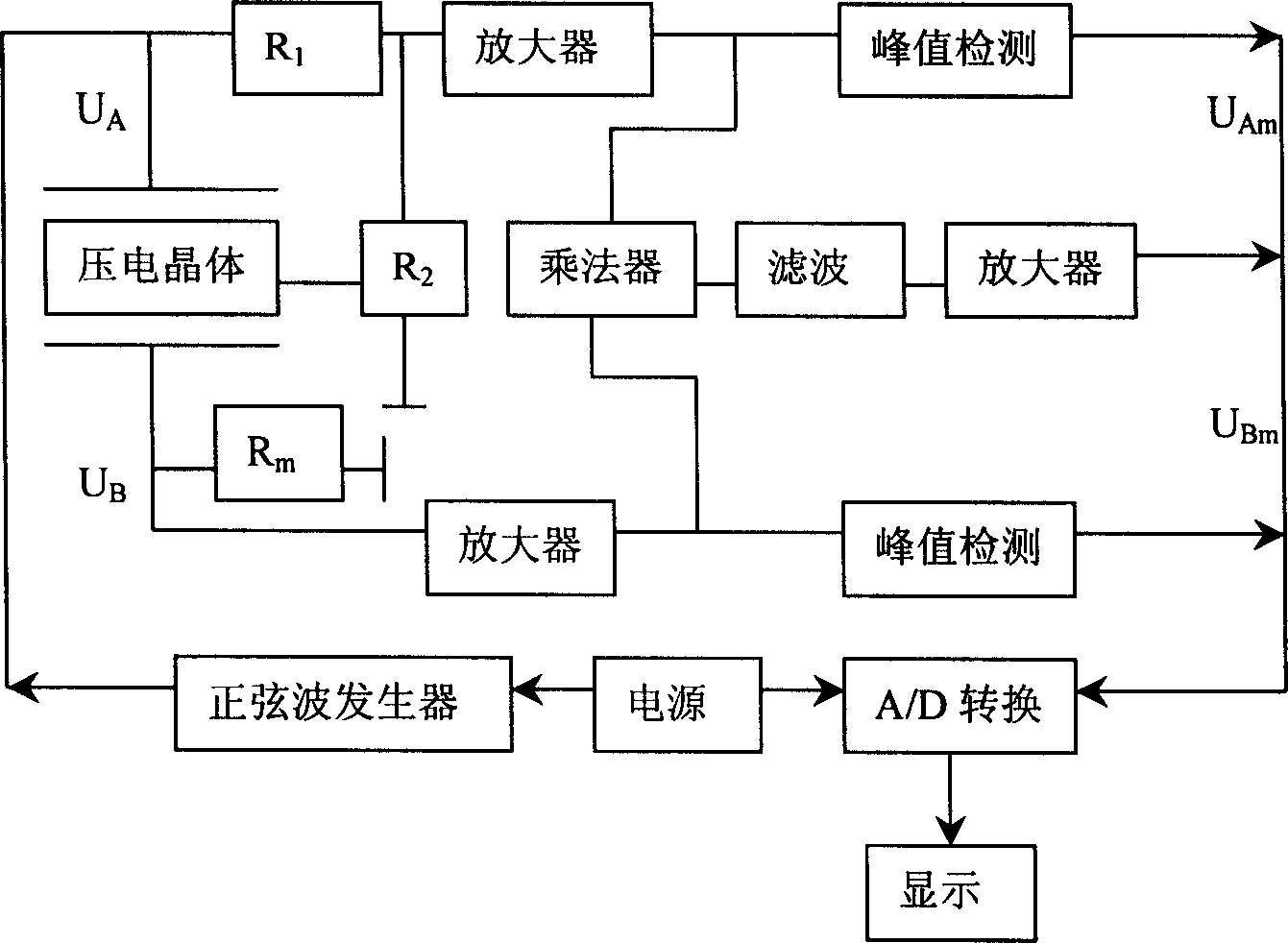

Method used

Image

Examples

Embodiment 1

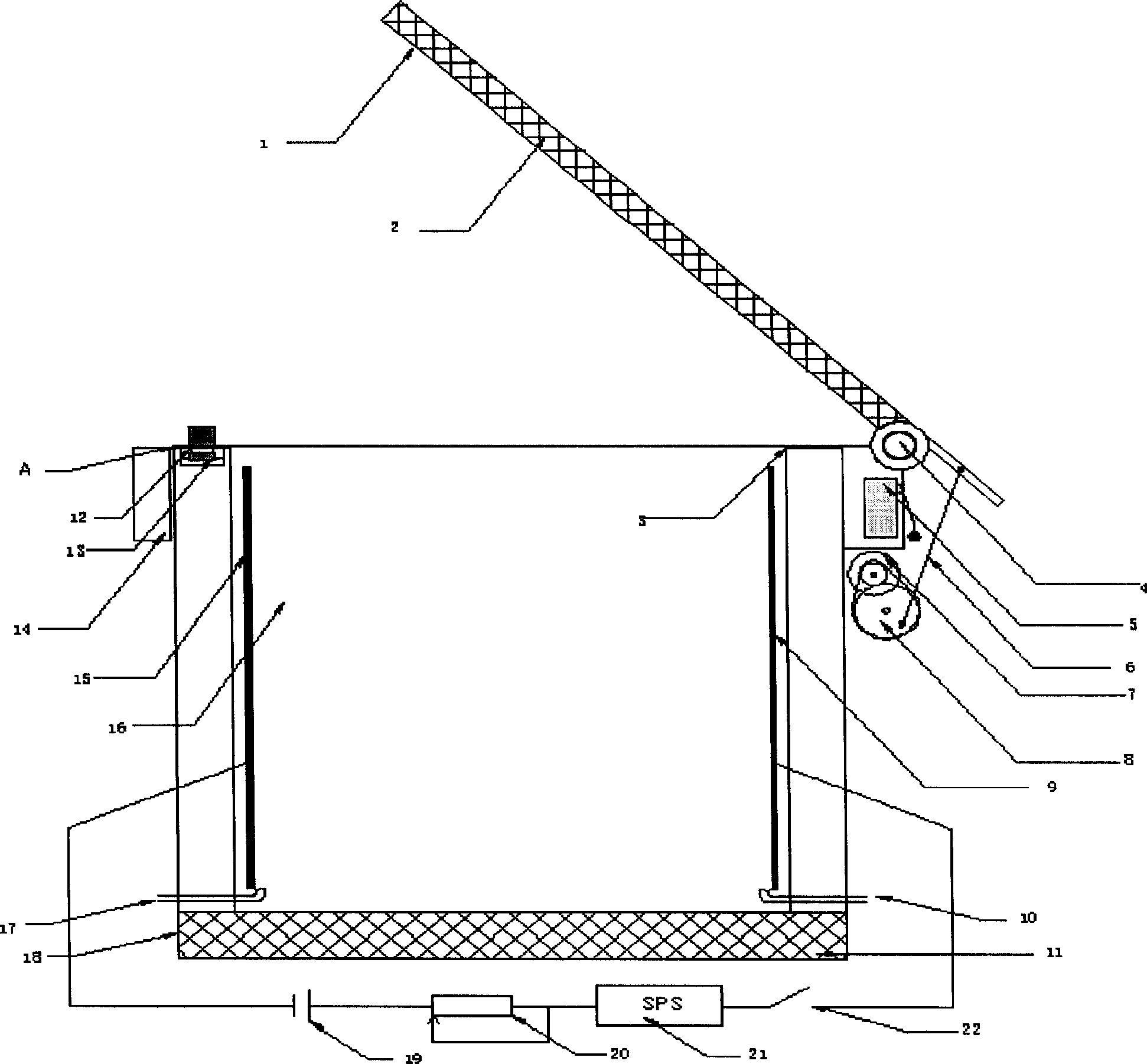

[0048] The particle real-time collection device in embodiment 1 is as image 3 and Figure 4 shown.

[0049] The particulate matter real-time monitoring device includes a monitor casing 18 of the device and a monitoring chamber 16 formed by an inner cavity of the casing. The inner wall of the monitoring chamber 16 is covered with desiccant layers 2 and 11 . There is a sampling port baffle 1 at the sampling port on the shell, and the baffle of the sampling port is automatically opened and closed by the baffle hinge 4, the baffle push rod 6, the baffle drive motor 7, and the reducer 8, and the limit switch is opened. 5 is used to open the baffle 1, and the closing limit switch 13 is used to close the baffle 1. After the baffle is closed, the monitoring chamber is closed by the sealing rubber pads 3, 12 and the baffle to close the electromagnetic lock 14. There are two sampling and weighing electrodes 9 and 15 in the monitoring room 2. The sampling and weighing electrodes 9 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com