Evaporator device

A technology for evaporators and distributors, which is applied in the field of vapor deposition devices, can solve the problems of not providing linear distributor orifices, etc., and achieve the effects of low energy loss, improved thermal isolation, and uniform symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

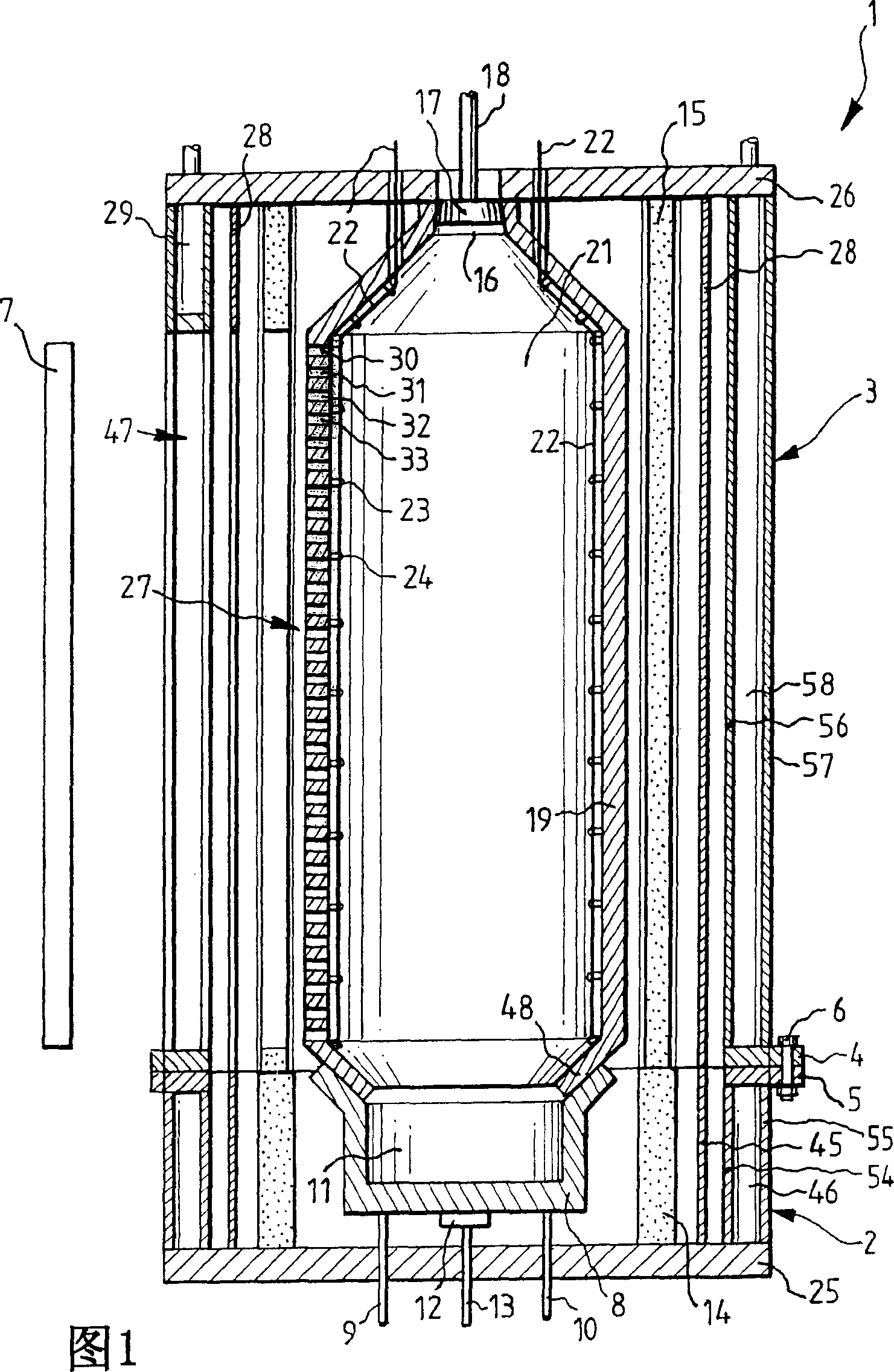

[0017] FIG. 1 shows a longitudinal sectional view of an evaporator device 1 consisting of a lower housing part 2 and an upper housing part 3 . The upper housing part 3 is here placed on the lower housing part 2 . The lower shell part 2 and the upper shell part 3 are fixed together by means of connecting clamps 4 , 5 and connecting pins 6 . When the lower housing part 2 is placed on the base 25 , the upper housing part 3 is closed by the cover 26 . As an alternative to the connecting lugs 4, 5, a simple plug connection can also be provided.

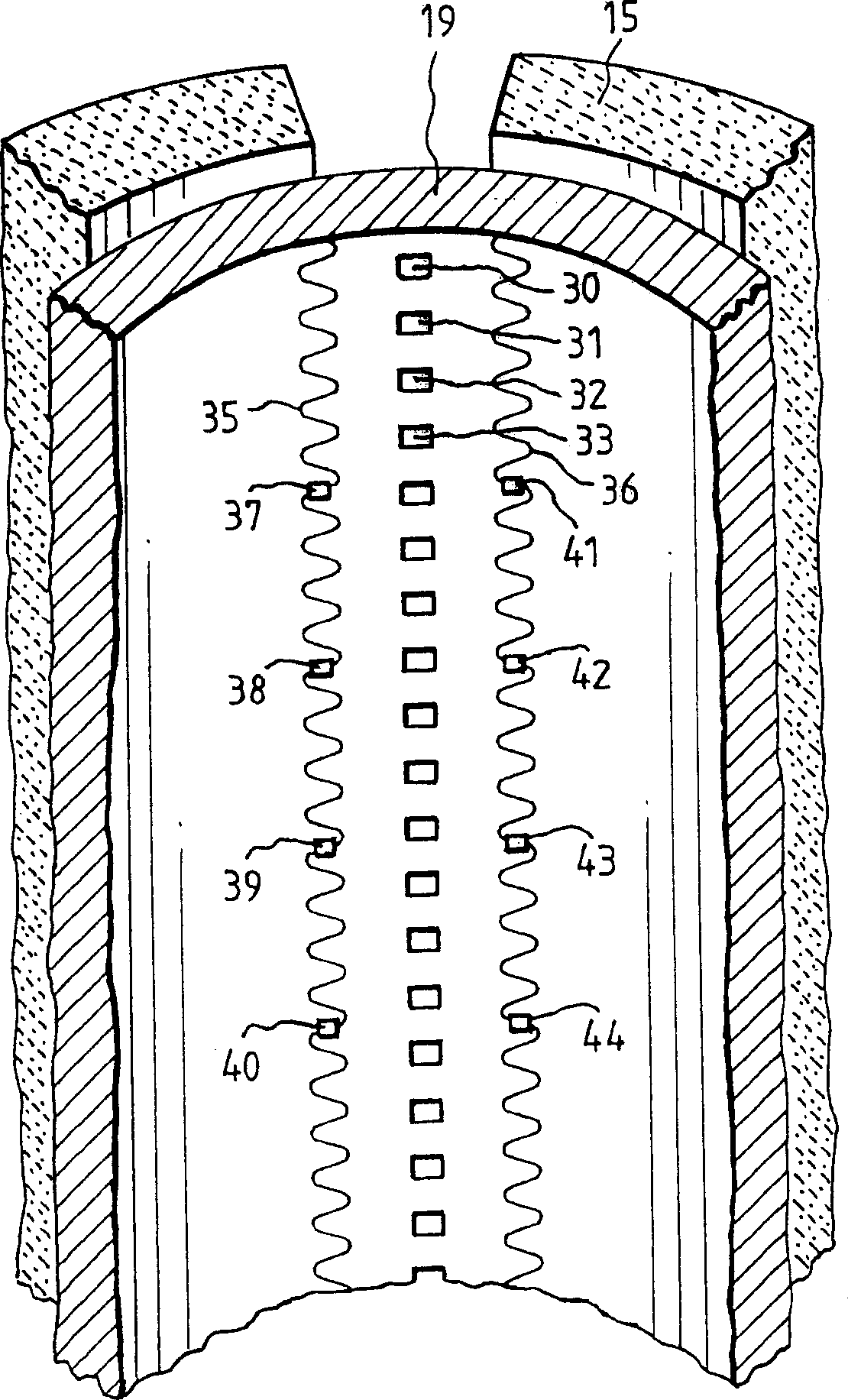

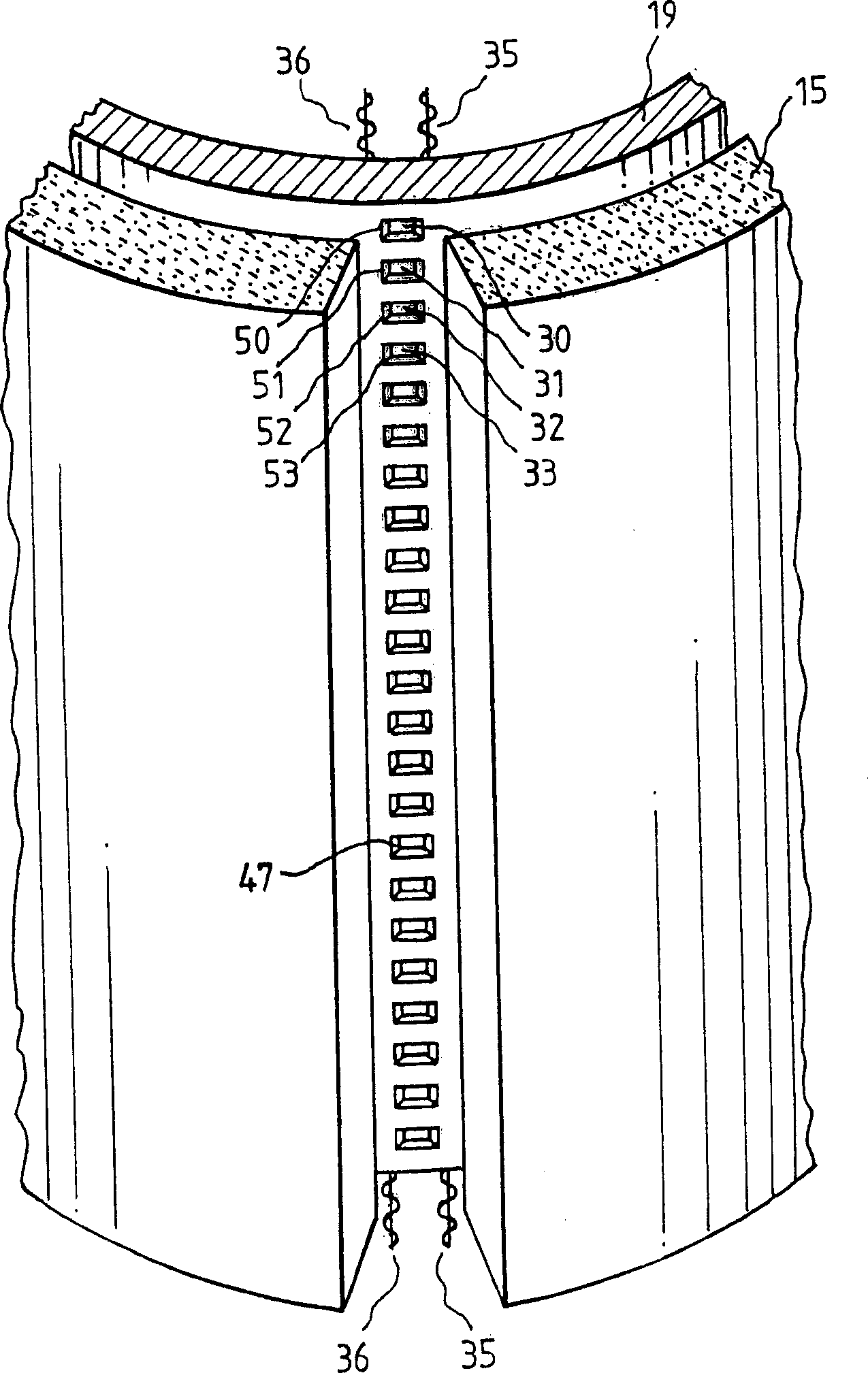

[0018] Inside the upper shell part 3 is provided an evaporator tube 19 comprising a number of nozzles 30, 31, 32, 33 arranged linearly one below the other through which steam can flow from the evaporator tube. escape. This vapor is deposited on the surface of the substrate 7 which can be moved through the evaporator device 1 into the plane of the drawing.

[0019] The crucible 8 is arranged below the evaporator tube 19 which rests on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com